Method for seepage filtration and drainage of deep sand and gravel layer by using seepage filtration and drainage device

A drainage device and seepage technology, applied in soil protection, construction, infrastructure engineering and other directions, can solve the problems of difficult installation, short installation length of water filter pipes, buried sediments, etc., to achieve convenient labor intensity and long service life. , The effect of good all-round water permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

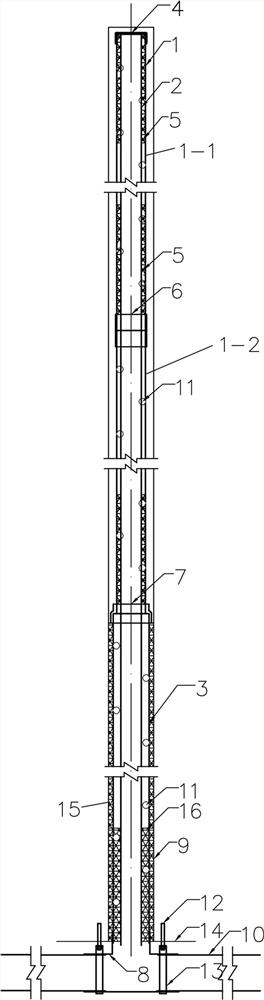

[0036] A seepage, filtration and drainage device for a deep sand and gravel layer, comprising an integral water filtering outer pipe formed by connecting a first water filtering flower tube 1 and a second water filtering flower tube 3, the integral water filtering outer tube is arranged in a drainage hole 9, and the drainage hole 9 Drill upward from the top arch 14 of the drainage hole to the elevation of the seepage gradient line in the sand and gravel layer. The first water filter flower tube 1 is located at the upper part of the second water filter flower tube 3 and its diameter is slightly smaller than that of the second water filter flower tube 3. A plurality of water filtering holes 11 are opened on the pipe walls of the water flower tube 1 and the second water filter flower tube 3;

[0037] The bottom end of the integral water filtering outer pipe is communicated with the drainage pipe 10 buried under the top arch 14 of the drainage hole through the tee joint 8, and the ...

Embodiment 2

[0051] A method of utilizing the above-mentioned seepage, filtration and drainage device to carry out seepage, filtration and drainage of deep sand and gravel layers, the method comprising the following steps:

[0052] Step 1: Use a down-the-hole drilling rig to drill a drainage hole 9 with a diameter of 100 mm on the center line of the top arch 14 of the drainage hole, and drill to the final hole at the elevation position of the seepage gradient line in the sand and gravel layer;

[0053] Step 2: Drill a plurality of water filtering holes 11 in the PVC water supply pipe to make the second water filtering flower tube 3, and wrap the water filtering geotextile outside the second water filtering flower tube 3 to form an externally fixed filtering geotextile layer 15;

[0054] Step 3: Cut out the soft permeable pipe 2 with the same length as the depth of the drainage hole 9;

[0055] Step 4: After wrapping the top section of the soft permeable pipe 2 with a water filter geotextil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com