Thin-wall steel cylinder concrete tower

A steel cylinder concrete and tower technology, applied in the direction of towers, building types, buildings, etc., can solve the problems of complex manufacturing, transportation, installation, and complicated procedures, and achieve the effects of short construction period, easy transportation, and easy assembly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

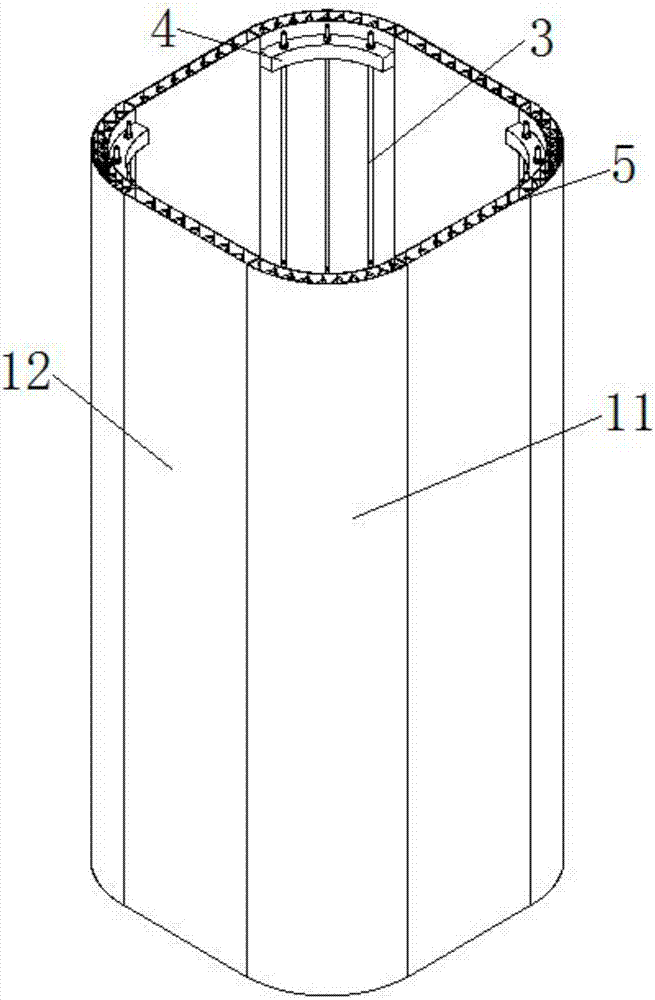

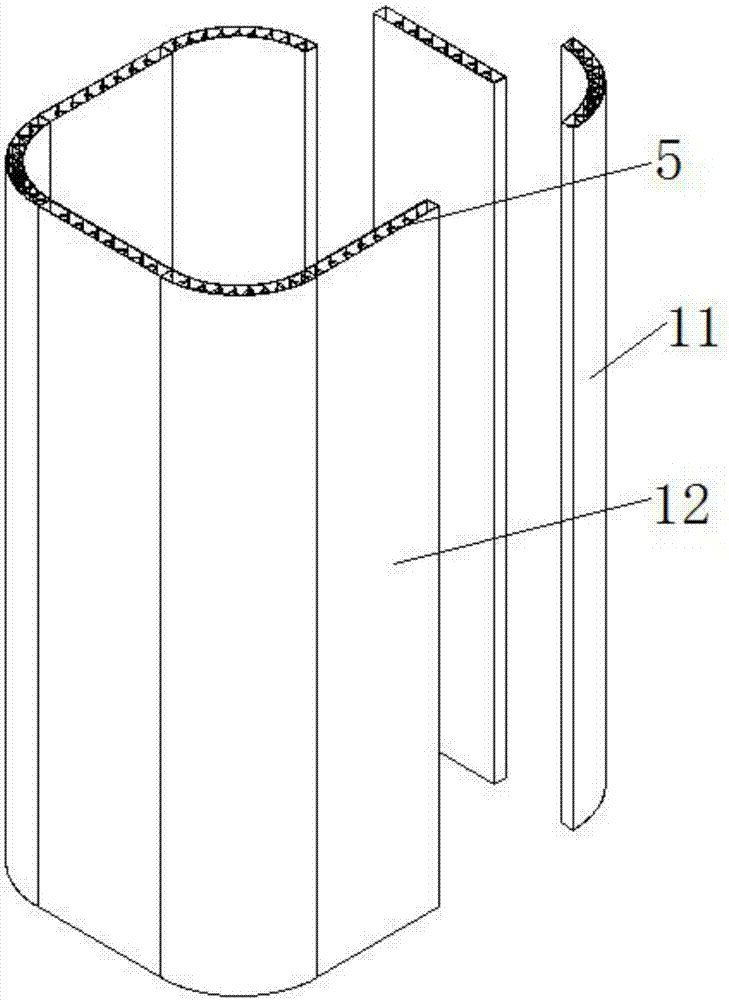

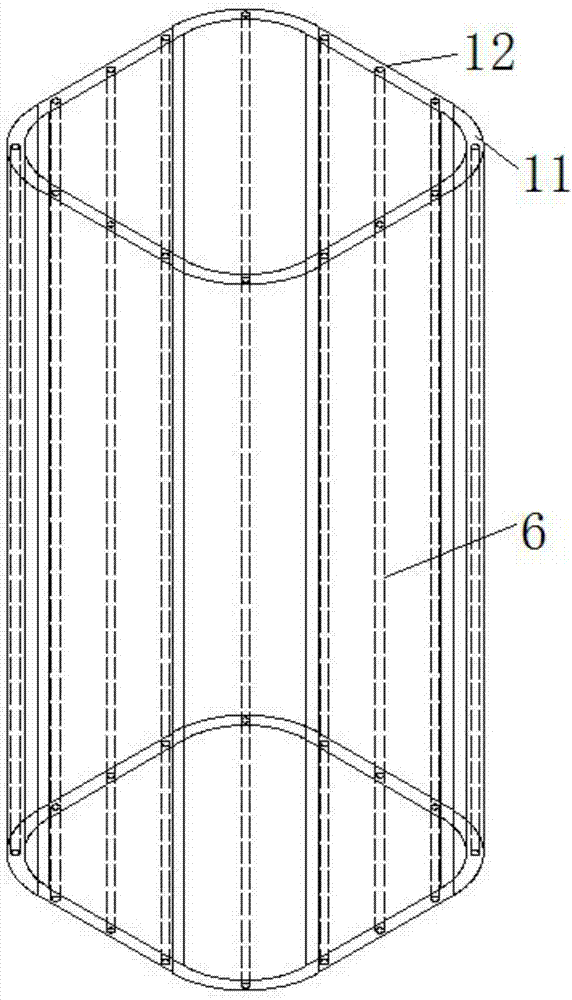

[0036] Embodiment: The thin-walled steel cylinder concrete tower in this embodiment includes a tower body, and the above-mentioned tower body is composed of a plurality of end-to-end connected wall fragment structures 1, and each of the above-mentioned wall fragment structures 1 is arranged vertically , and both are cavity structures with internal hollows and open upper and lower ends. The side ends of two adjacent cylinder wall fragment structures 1 are connected and fixed to each other and communicated through through holes correspondingly provided at the side ends. Each of the above cylinder wall fragments The structure 1 is provided with reinforcement ribs between the inner wall and the outer wall, and concrete is poured (not shown in the figure), and a plurality of externally prestressed steel strands 3 are vertically arranged on the inner wall of the tower cylinder, and the concrete is poured. At the same time, the concrete in the single tube wall segment structure 1 is p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com