Guide vane position feedback device for horizontal hydraulic turbine set

A guide vane position and feedback device technology, applied in safety devices, reaction engines, mechanical equipment, etc., can solve problems such as poor stability, automation process failure, low accuracy, etc., to improve reliability, strong environmental applicability, High sensitivity effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

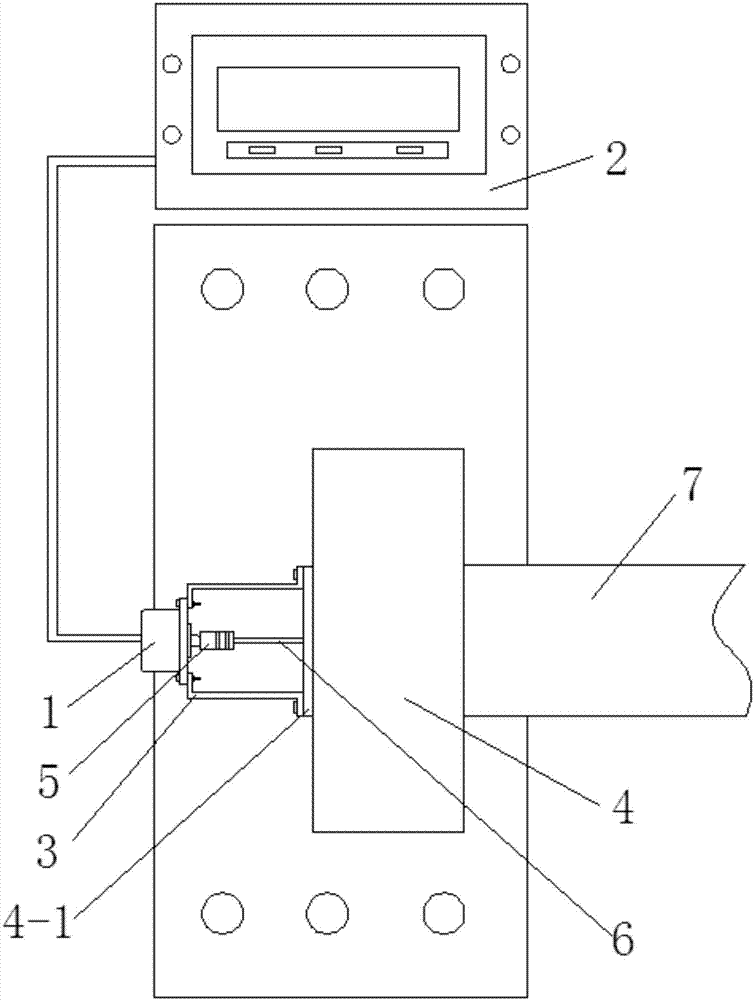

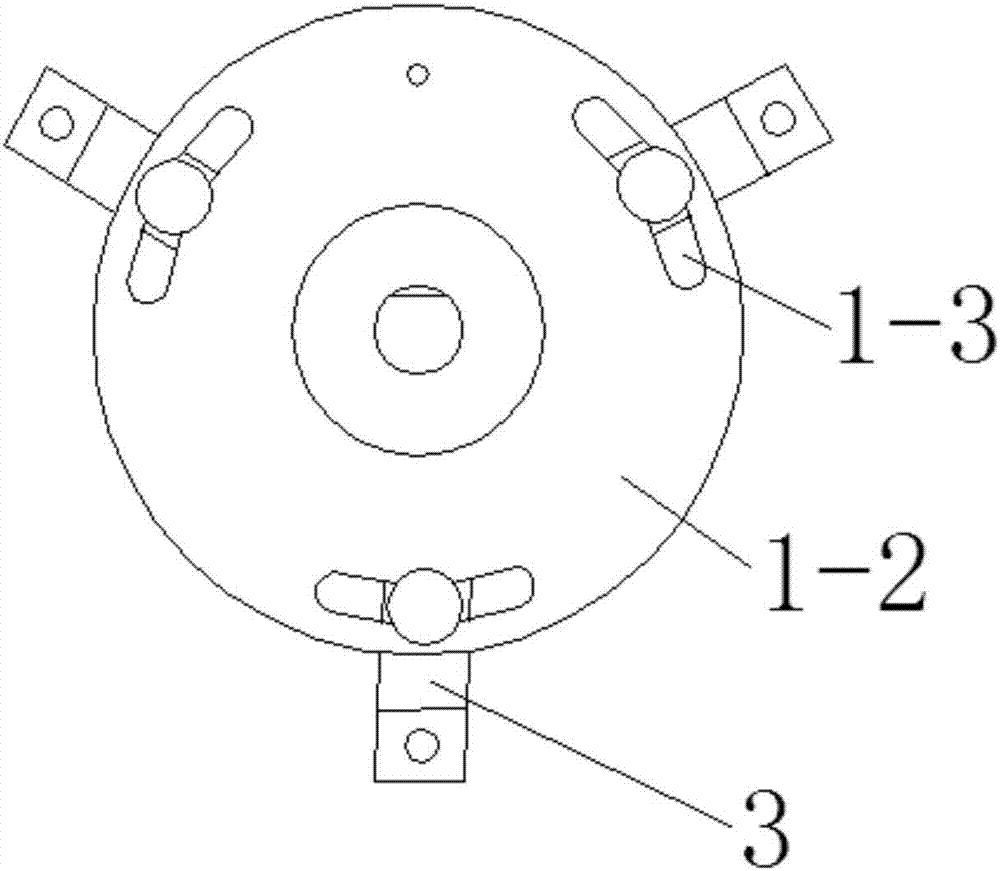

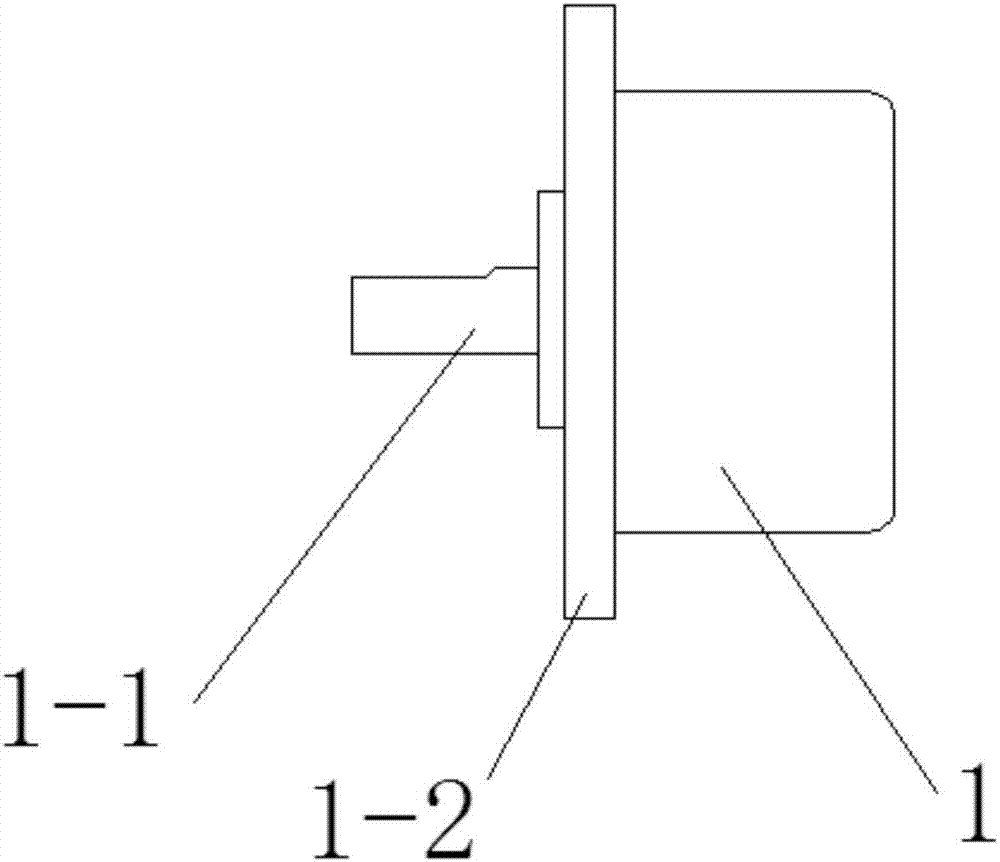

[0014] Embodiment 1: The guide vane position feedback device for the horizontal hydraulic turbine unit in this embodiment includes a magnetic non-contact angle sensor 1, a measurement display controller 2, three support members 3 and a coupling 5. The support member 3 is composed of a A connecting plate 3-1, the middle long strip 3-2 and the second connecting plate 3-3 form an integral structure, the first connecting plate 3-1 is provided with bolt holes 3-4, the middle long strip 3-2 The first connecting plate 3-1 and the second connecting plate 3-3 are respectively arranged on the two sides of the plate, and the first connecting plate 3-1 and the second connecting plate 3-3 are respectively arranged on the middle long plate 3-2. On the two broad end faces, the first connecting plate 3-1 and the second connecting plate 3-3 are respectively perpendicular to the middle long strip 3-2, and the second connecting plate 3-3 of each support The annular flange 4-1 of the speed gear r...

specific Embodiment approach 2

[0017] Embodiment 2: The difference between this embodiment and Embodiment 1 is that the measurement and display controller 2 is installed on the volute boss of the horizontal water turbine.

specific Embodiment approach 3

[0018] Embodiment 3: The difference between this embodiment and Embodiment 2 is that the measurement and display controller 2 is installed on the volute boss of the horizontal water turbine through screws.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com