Compound pipe assembly for conveying sea water and manufacturing method thereof

A technology of composite pipes and components, applied in the direction of pipes/pipe joints/fittings, applications, pipes, etc., can solve the problems of impact resistance, poor adhesion, damage, and easy peeling of the inner coating, so as to increase adhesion and prevent Effect of pipe clogging, ideal corrosion protection performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

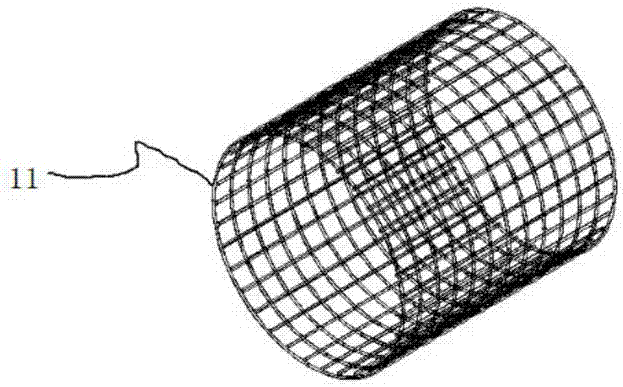

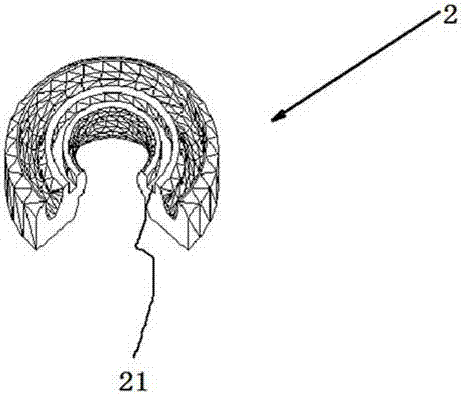

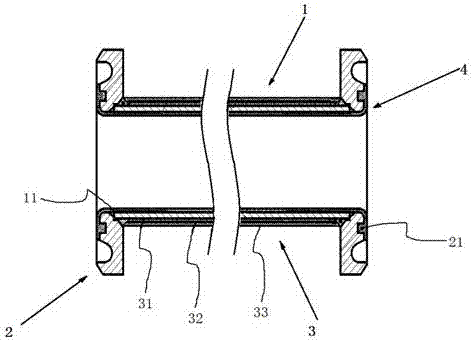

[0019] attached Figures 1 to 3 , the three drawings show the appearance and specific structure of an embodiment of the composite pipe assembly for seawater transportation proposed by the present invention. The composite pipe comprises a base pipe 1, an annular steel mesh 11 surrounding the inner wall of the end of the base pipe, and flanges 2 arranged at both ends of the base pipe 1, and the flange 2 is connected to the base pipe 1. The inner surface of the connection end is provided with an annular groove 21, and the outer surface and the inner surface of the base pipe 1 are respectively provided with an outer anti-corrosion layer 3 and an inner anti-corrosion layer 4, wherein the annular steel mesh 11 is located in the base pipe 1 for anti-corrosion In the layer 4, the function of the annular steel mesh 11 is to integrate with the inner anti-corrosion layer 4, so that the inner anti-corrosion layer 4 is strengthened, and the adhesion between it and the inner wall of the bas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com