Fluid heating device

一种加热装置、流体的技术,应用在流体加热器、欧姆电阻加热装置、水加热器等方向,能够解决电路功率因数降低、电压降低等问题,达到改善电路功率因数、提高设备效率的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

[0058] An embodiment of the fluid heating device of the present invention will be described below with reference to the drawings.

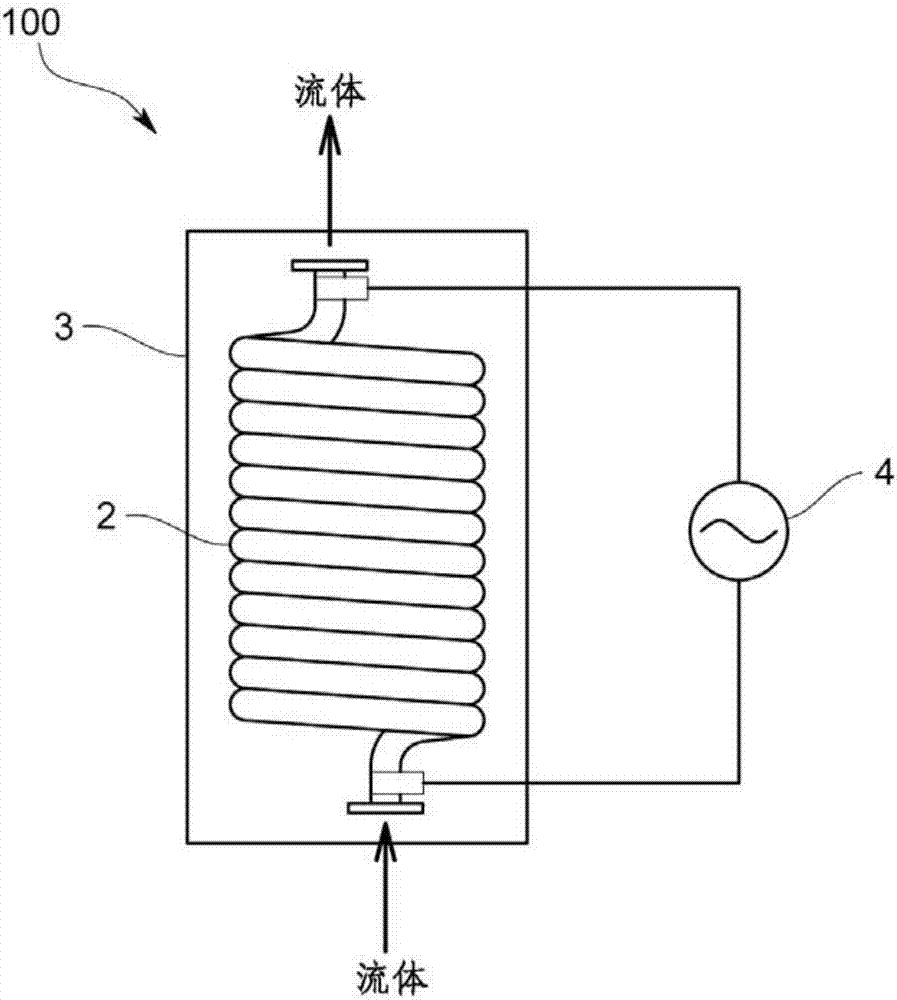

[0059] Such as figure 1 As shown, in the fluid heating device 100 of this embodiment, a three-phase AC power source 4 is connected to a hollow conductor tube 2. A fluid (for example, water, saturated steam, or superheated steam, etc.) flows inside the conductor tube 2 and passes through The conductor tube 2 is directly energized by applying a three-phase AC voltage, and uses the Joule heat generated by the internal resistance of the conductor tube 2 to heat the conductor tube 2 to heat the fluid flowing in the conductor tube 2.

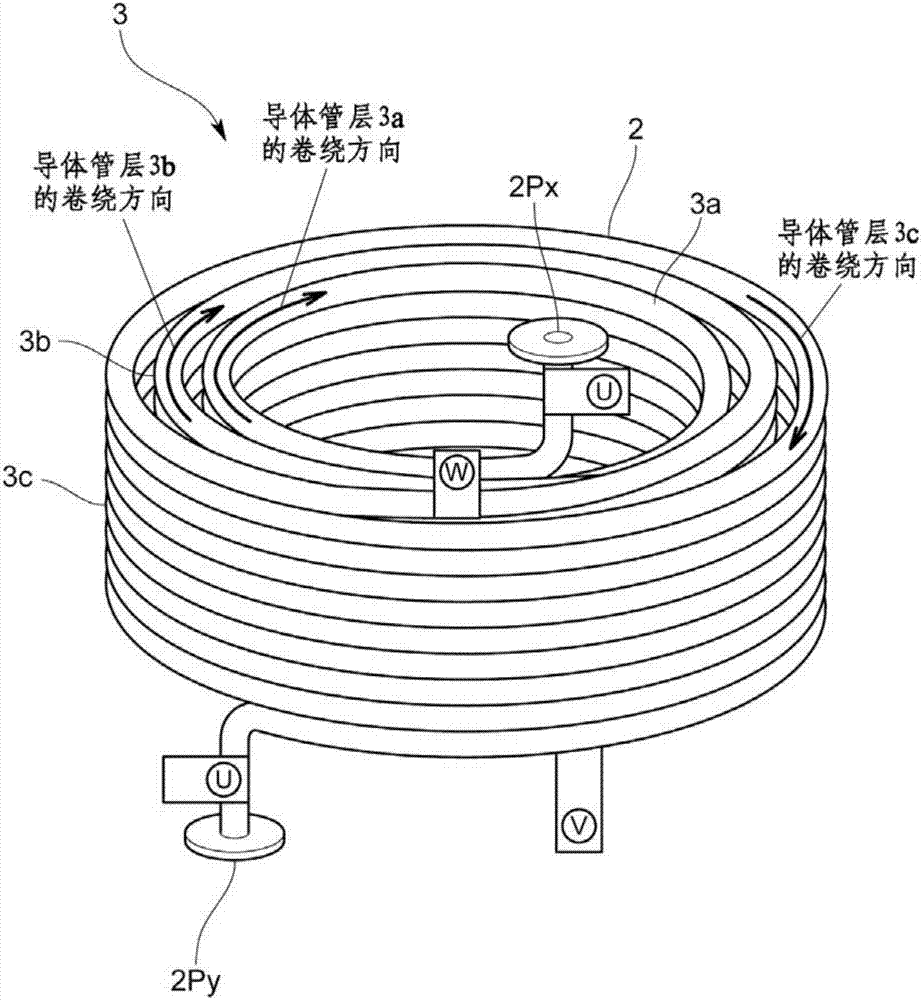

[0060] Specifically, the fluid heating device 100 includes a fluid heating part 3, which is formed by winding a single conductor tube 2 or a plurality of conductor tubes 2 electrically connected to each other into a spiral 3N (N is 1 or more) Integer) layer of conductor tube layer.

[0061] The fluid heating part 3 is such as ...

no. 2 approach

[0090] Next, the second embodiment of the present invention will be described.

[0091] The fluid heating device 100 of this embodiment has a fluid heating part 3 composed of one conductor tube 2 or a plurality of conductor tubes 2 electrically connected to each other.

[0092] The fluid heating part 3 is such as Figure 7 ~ Figure 10 As shown, various structures can be adopted.

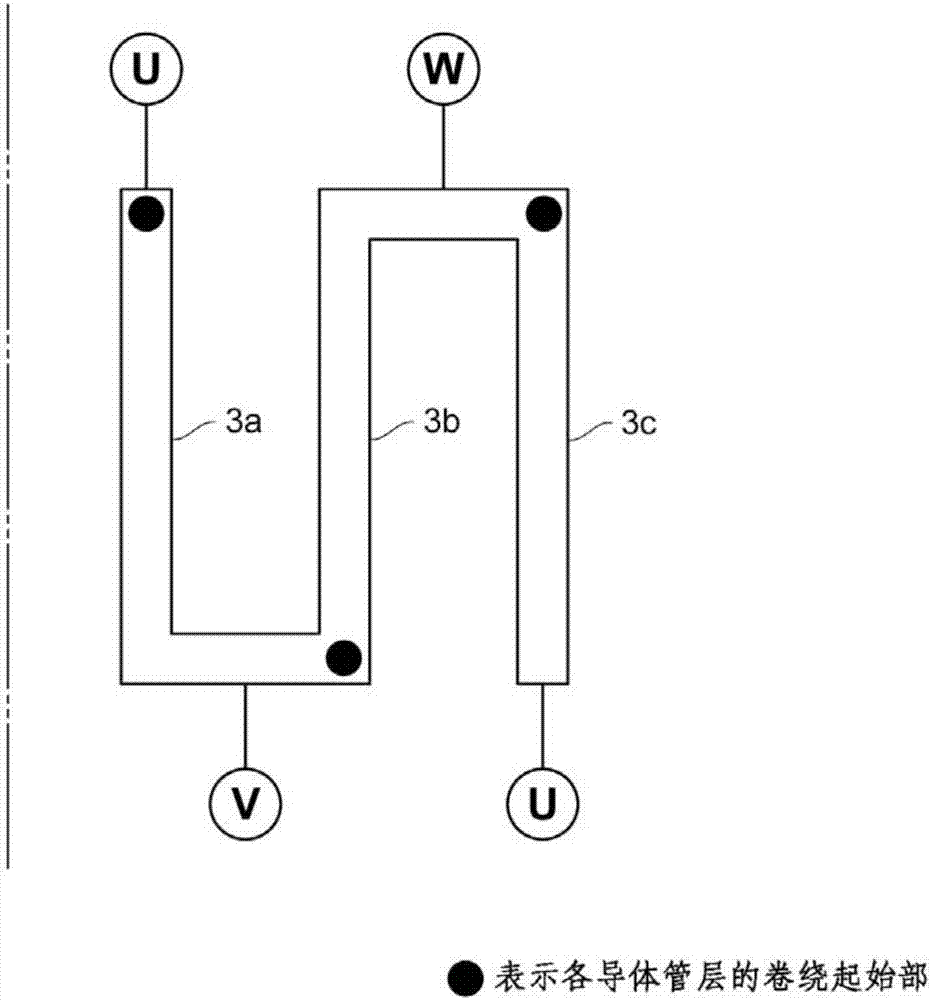

[0093] Figure 7 The fluid heating section 3 shown is composed of two conductor tubes 2 electrically connected by an AC circuit including an AC power source 4. The impedance value of the entire fluid heating section 3 is equally divided into even-numbered parts (in this embodiment). The two ends of the split elements 3a and 3b are applied with an AC voltage from the AC power supply 4.

[0094] Each divided element 3a, 3b is a conductor tube layer formed by winding a conductor tube 2 having fluid inlets and outlets 2Px, 2Py at both ends through which the fluid to be heated flows in or out. In addition, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com