Optimization method for slit-type casing treatment parametrization design

An optimization method and casing processing technology, which is applied in the field of aero-engines, can solve problems such as the decrease in efficiency of compressor design points, and achieve the effects of saving human resource costs, improving design efficiency, and shortening the design cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

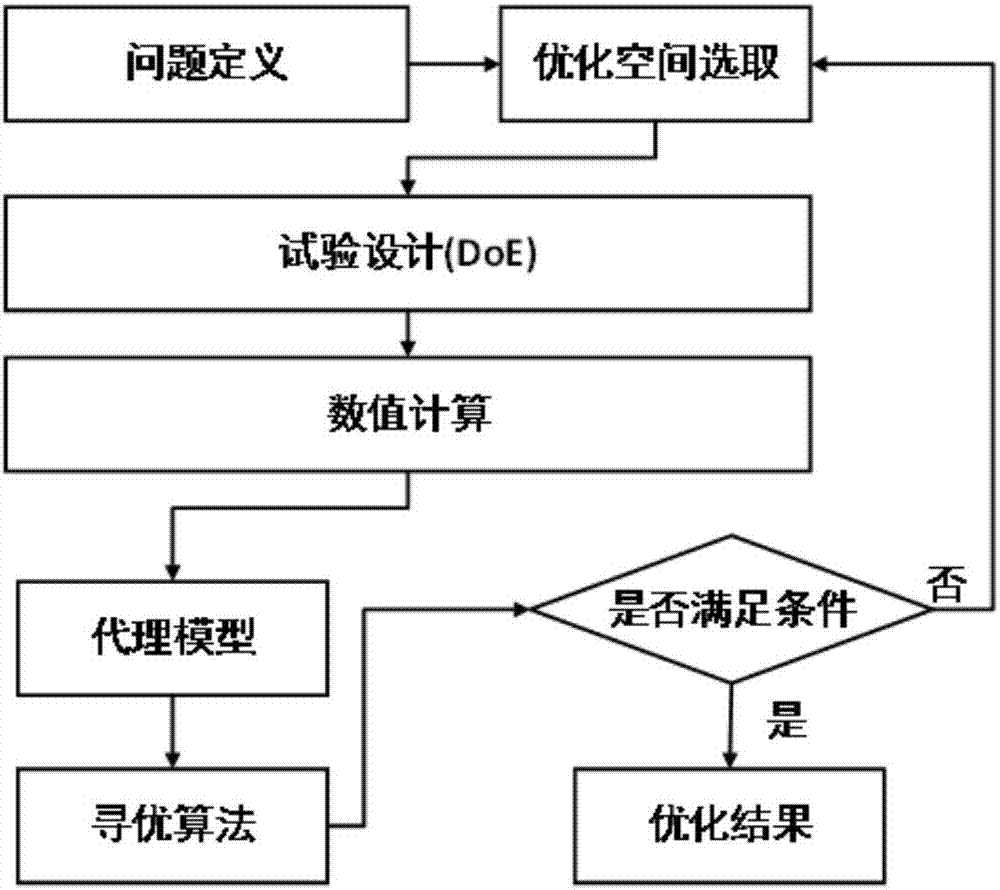

[0019] Such as figure 1 As shown, this embodiment adopts the axial folding line oblique seam casing of a typical axial flow compressor, and specifically includes the following steps:

[0020] Step 1. Select the geometric parameter variable to be optimized for casing processing and its corresponding spatial range to conduct experimental design and construct a surrogate model.

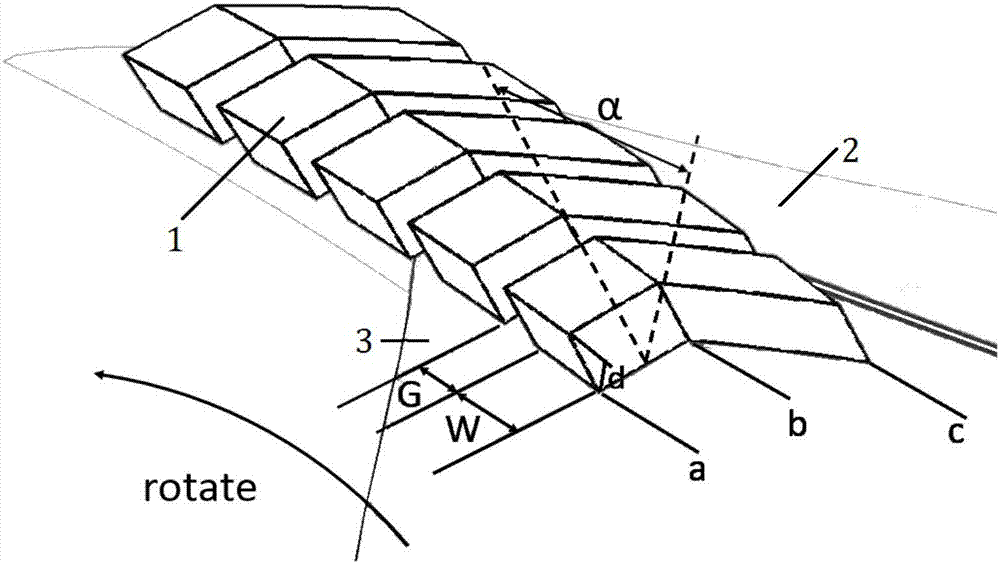

[0021] Such as figure 2 As shown, the geometric parameter variables are: leading edge axial position a, trailing edge axial position c, casing processing depth d, casing processing inclination angle α, casing processing knuckle position (b-a) / (c-a) and The casing handles the opening ratio W / (W+G).

[0022] The geometric parameter variables need to be given with reference to the specific structure and flow field, and the corresponding spatial range is:

[0023] 1) Axial position a of the leading edge: depends on the axial coverage of the slot and the axial position of the slot. According to engineerin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com