Residue soil polymer production device for shielding operation

A production device and polymer technology, applied to mixers with rotating stirring devices, mixers, mixing methods, etc., can solve the problem of reducing the particle size of dregs polymer products, low production efficiency of dregs polymers, and difficulty in product dissolution and other problems, to achieve the effects of strong implementability, reduced dissolution time, and scientific and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

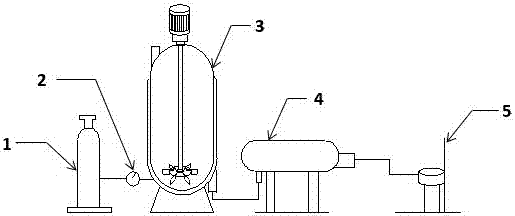

[0011] Attached below figure 1 The present invention will be described in further detail.

[0012] A muck polymer production device used for shield operation, including a heating type stirring tank 3, a gas source bottle 1, a pressure reducing valve 2, a cooling extruder 4, and a packaging machine 5. The muck polymer raw material is heated After the stirred tank 3, the gas source bottle 1 is opened, and the gas in the gas source bottle 1 flows into the heated stirred tank 3 through the pressure reducing valve 2. The heated stirred tank 3 is heated and strongly stirred. After the raw material is melted into a high-viscosity fluid and filled with bubbles, the fluid-like slag polymer material enters the cooling extruder 4, where it is cooled to a solid and formed into a granular slag polymer product, and the granular slag polymer product enters the packaging machine 5 for processing. The product is packaged and sealed. The inner material of the heating stirring tank 3 is composite ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com