A high-frequency welding equipment for copper products

A technology for high-frequency welding and copper products, applied in the direction of high-frequency current welding equipment, welding equipment, welding equipment, etc., can solve the problems of wasting time, wasting manpower, poor heat dissipation, etc., achieve high quality, promote up and down convection, and ensure cooling efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

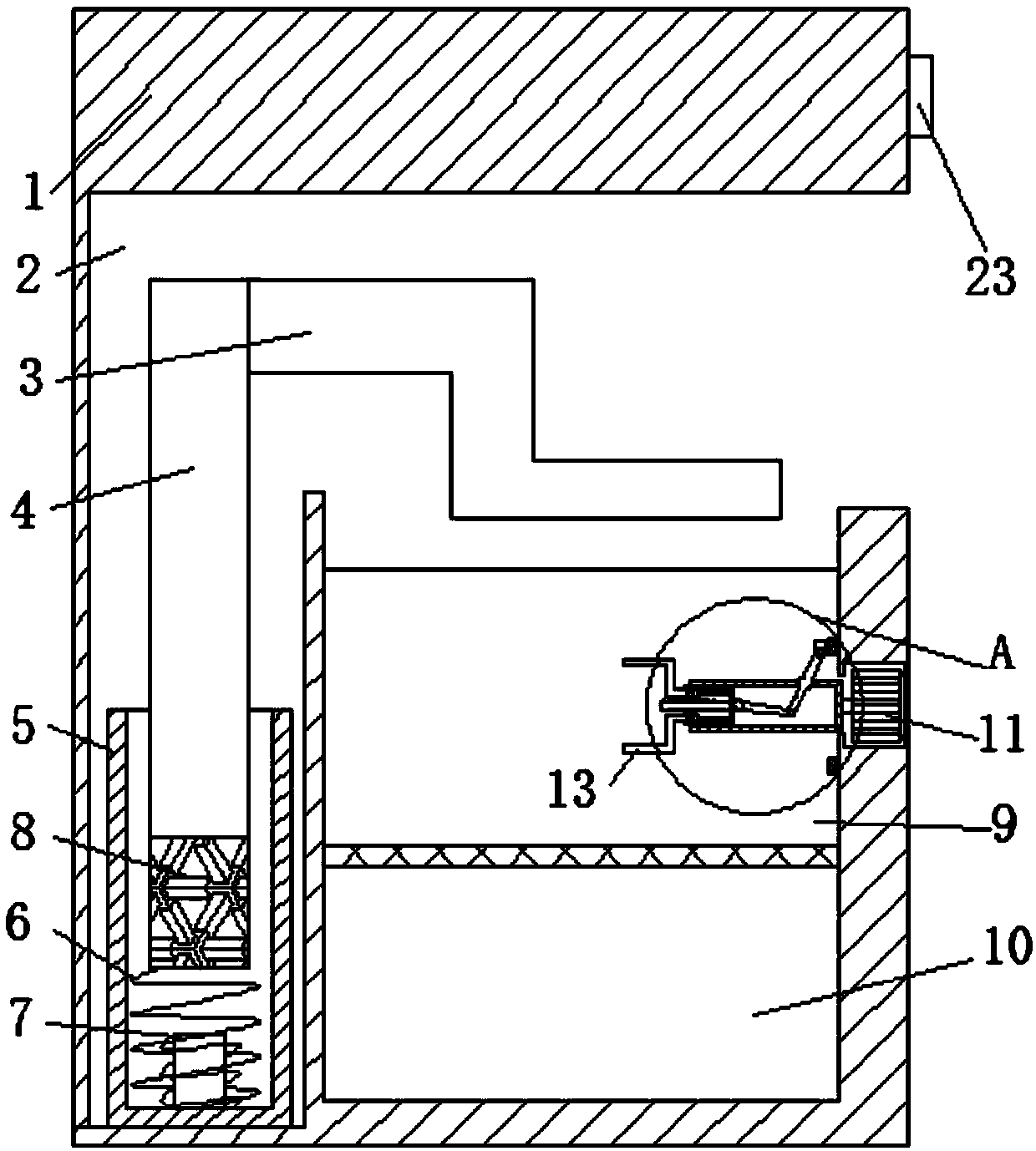

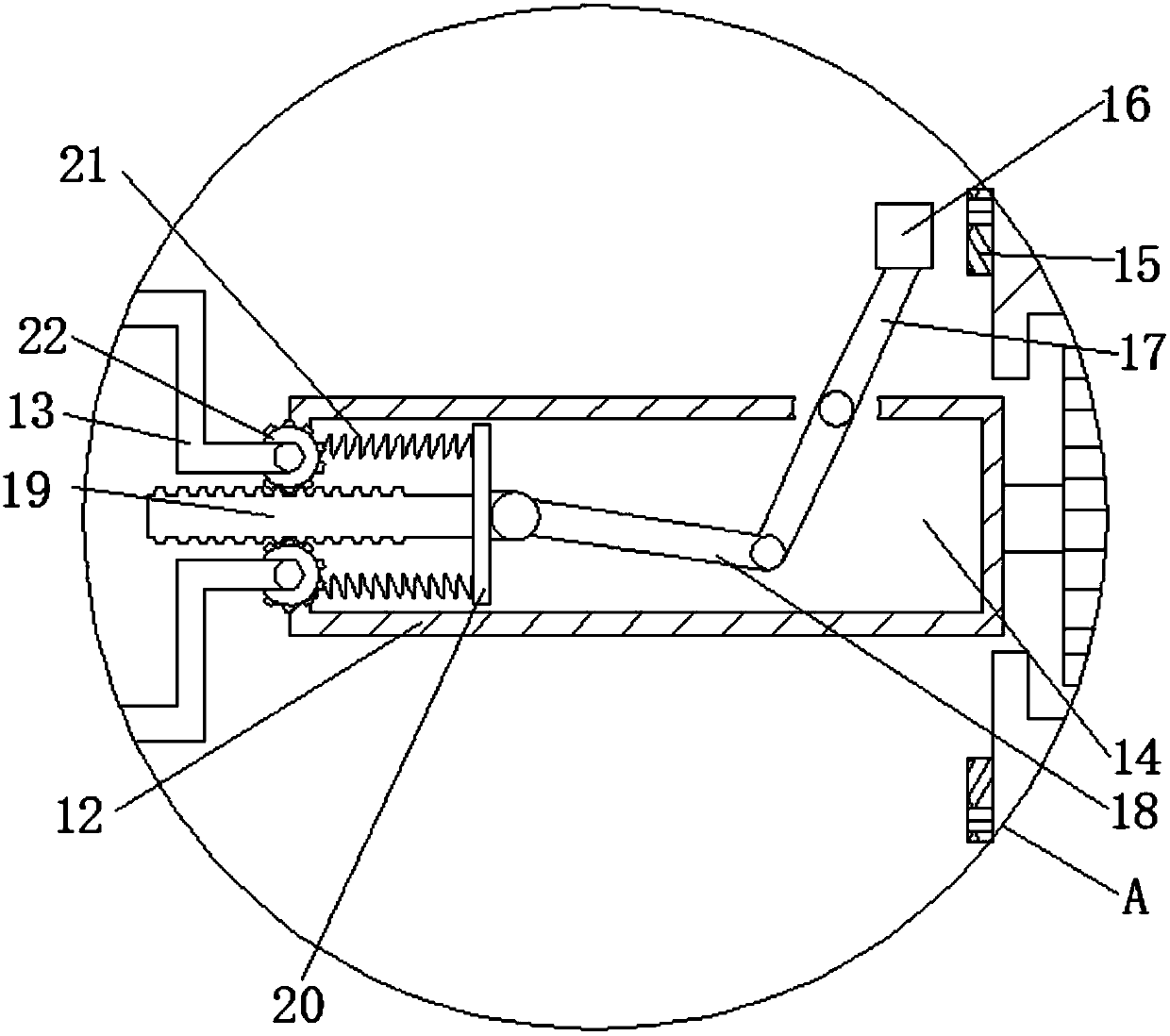

[0011] In order to further understand content of the present invention, the utility model is described in detail in conjunction with accompanying drawing and embodiment. It should be understood that the examples are only for explaining the present invention rather than limiting it.

[0012] A high-frequency welding equipment for copper products, comprising a device body 1, a first installation groove 2 is arranged on the device body 1, a support plate 3 is arranged inside the first installation groove 2, and a connecting rod 4 is connected to one end of the support plate 3, and a connecting rod 4 is connected to the first installation groove 2. The lower end of the rod 4 is sleeved with a sleeve 5, the sleeve 5 is connected to the bottom wall of the first installation groove 2, the inner bottom wall of the sleeve 5 is connected with the lower end of the connecting rod 4 through the first spring 6, and the first spring 6 is inserted An electromagnet 7 is connected, and the elec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com