Die-cutting machine applicable to printing products of different widths

A technology for die-cutting machines and printed products, applied in thin material processing, object separation, metal processing, etc., can solve the problems of unable to meet the needs of production, consume a lot of labor force, and easily make mistakes, so as to reduce the risk of damaged printed products Chance, quality boost, less error-prone effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

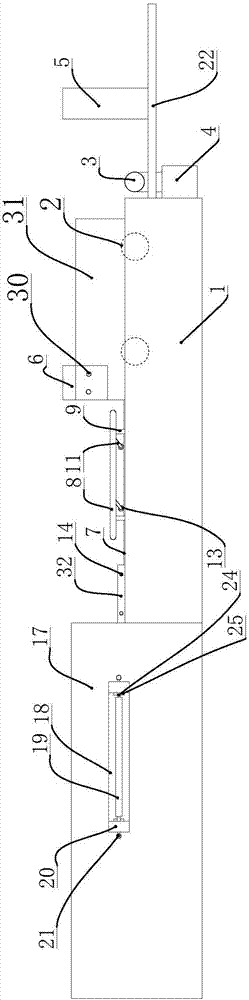

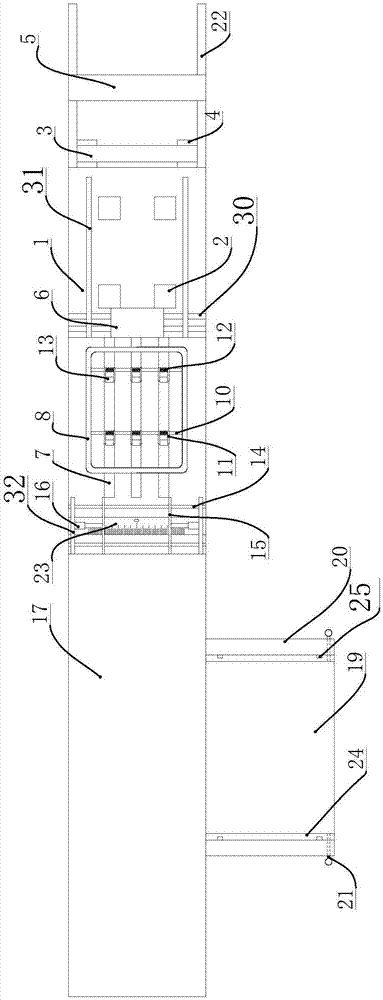

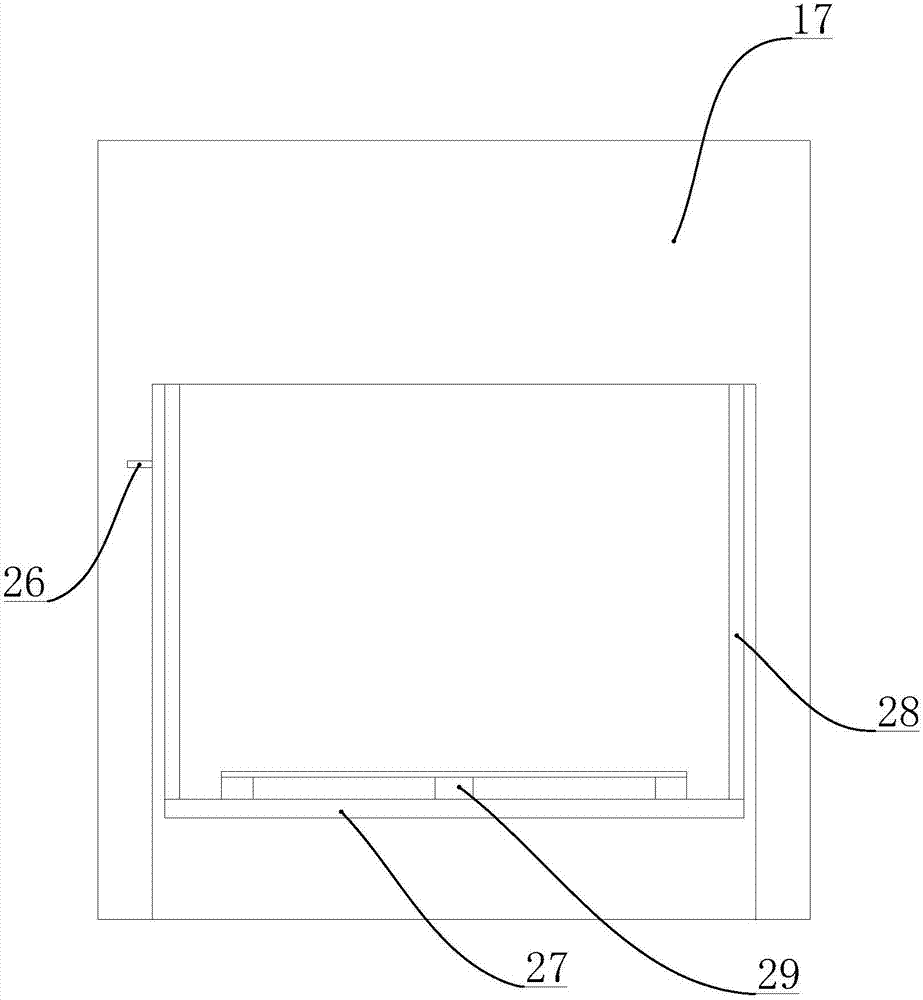

[0027] Such as Figure 1-3 As shown, a die-cutting machine suitable for printed products of different widths, including a feeding device, a feeding adjustment device, a mold fixing device and a discharging mechanism;

[0028] The feeding device includes a support platform 1, and a plurality of sets of drive pulleys 2 arranged on the support platform 1, the top of the drive pulley 2 is higher than the support surface of the support platform 1, and the front part of the support platform 1 is provided with a A jacking rod 3 placed horizontally, a jacking cylinder 4 is arranged at both ends of the jacking rod 3, the cylinder barrel of the jacking cylinder 4 is fixed with the support platform 1, and the piston of the jacking cylinder 4 The top of the bar is fixed to the end of the jacking rod 3, and a front block 5 is also arranged on the front portion of the support platform 1, and a rear block 6 is fixed above the support platform 1, and the rear block 6 is fixed on the top of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com