Metal wheel hub injection molding technology

A hub and metal technology, applied in the field of metal hub injection molding technology, can solve problems such as easy cracks, falling off blocks, unstable quality, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

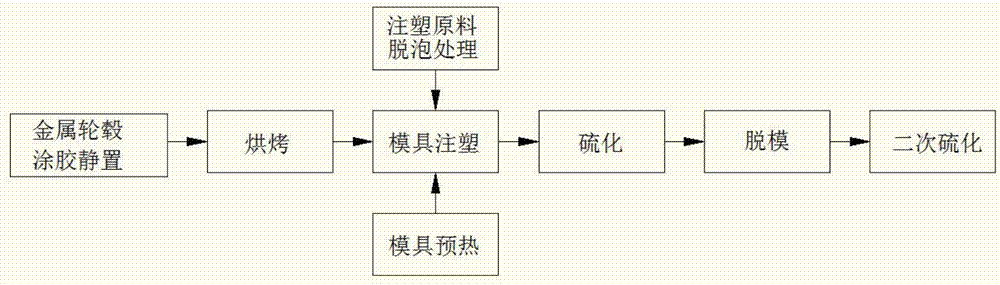

Method used

Image

Examples

Embodiment 1

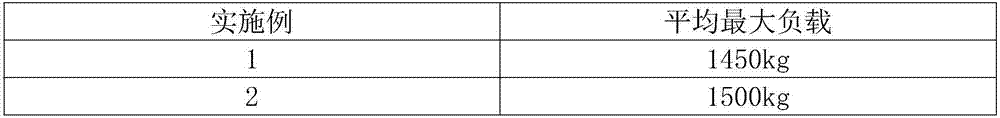

[0021] A metal wheel hub injection molding process, including the surface of the metal hub with rubber coating and standing, preheating and baking, mold injection molding, vulcanization and demoulding and secondary vulcanization, firstly apply adhesive glue on the surface of the metal hub and then let it stand, the adhesive glue The coating thickness of the glue is 25 μm to 45 μm, the temperature of the static condition is 35 ° C, the humidity is 55%, and the static time is 40 min to 60 min. Place the rubberized metal hub after standing in an oven at 100°C and bake for 4 to 6 hours, evenly apply a release agent on the inner surface of the injection mold, and heat and keep the injection mold to make the mold temperature 90°C to 110°C. After defoaming the heated prepolymer polyurethane raw material for 20 to 40 minutes, assemble the metal hub in a mold with a temperature of 90°C to 110°C for pouring. The temperature of the pouring raw material is 70°C to 85°C, and the pouring pre...

Embodiment 2

[0023] A metal wheel hub injection molding process, including the surface of the metal hub with rubber coating and standing, preheating and baking, mold injection molding, vulcanization and demoulding and secondary vulcanization, firstly apply adhesive glue on the surface of the metal hub and then let it stand, the adhesive glue The coating thickness of the glue is 25 μm to 45 μm, the temperature of the standing conditions is 30°C, the humidity is 50%, and the standing time is 40min to 60min. Place the rubber-coated metal hub after standing in an oven at 100°C and bake for 6 hours, apply a release agent evenly on the inner surface of the injection mold, and heat and keep the injection mold to make the mold temperature 100°C. After defoaming the heated prepolymer polyurethane raw material for 20 to 40 minutes, assemble the metal hub in a mold with a temperature of 90°C to 110°C for pouring. The temperature of the pouring raw material is 70°C to 85°C, and the pouring pressure of ...

Embodiment 3

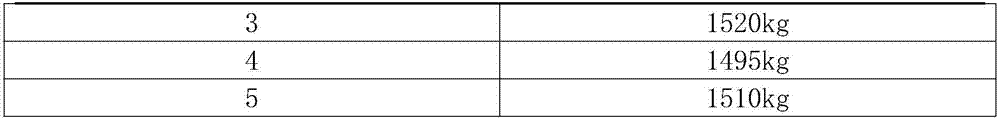

[0025] A metal wheel hub injection molding process, including the surface of the metal hub with rubber coating and standing, preheating and baking, mold injection molding, vulcanization and demoulding and secondary vulcanization, firstly apply adhesive glue on the surface of the metal hub and then let it stand, the adhesive glue The thickness of the glue is 25 μm to 30 μm, the temperature of the standing conditions is 28°C, the humidity is 45%, and the standing time is 40minmin. Place the rubber-coated metal hub after standing in an oven at 100°C and bake for 6 hours, apply a release agent evenly on the inner surface of the injection mold, and heat and keep the injection mold to make the mold temperature 100°C. After defoaming the heated prepolymer polyurethane raw material for 20 hours, assemble the metal hub in a mold with a temperature of 90°C for pouring operation. The temperature of the pouring raw material is 70°C, and the pouring pressure of the raw material is 3.2MPa; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com