Moment levelling control method for composite press and levelling device of composite press

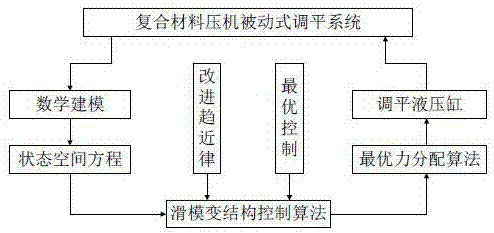

A composite material and control method technology, applied in special data processing applications, instruments, geometric CAD, etc., can solve the problems of low leveling accuracy, weak anti-interference ability, low leveling efficiency, etc., and achieve simplified mechanical structure, Parameter perturbation and system interference are good, and the effect of improving robustness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] The present invention will be described in detail below with reference to the drawings and specific embodiments.

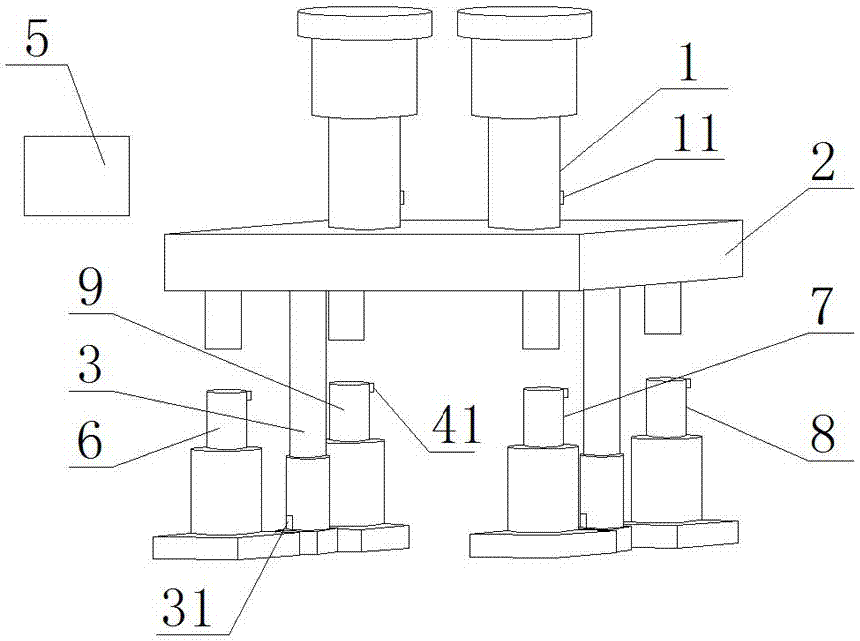

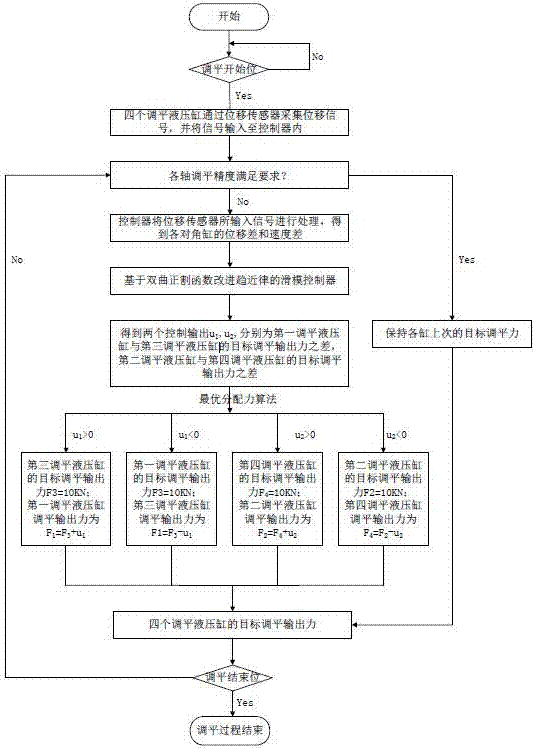

[0044] figure 1 with Figure 4 A leveling device for a composite press is characterized, comprising a master cylinder 1, a slider for mounting molds 2, a return cylinder 3, and a controller 5 arranged from top to bottom; the hydraulic rod of the master cylinder 1 is fixed on The upper end surface of the slider 2, the hydraulic rod of the return cylinder 3 is fixed on the lower end surface of the slider 2; the four corners below the slider 2 are respectively provided with leveling hydraulic cylinders; the leveling mechanism also includes a master cylinder 1 first displacement sensor 11 for displacement signals, first pressure sensor 31 for collecting pressure signals of return cylinder 3, and second displacement sensor 41 for collecting displacement signals of the leveling hydraulic cylinder; the controller 5 includes data collection connected by electrical sig...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com