Elastic vehicle wheel

A wheel and elastic technology, applied in the field of tram components, can solve the problems of reducing unsprung mass, easy wear of elastic wheels, poor noise reduction effect, etc., and achieve the effect of meeting application requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

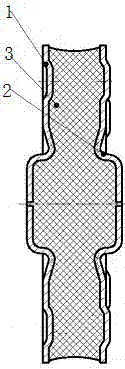

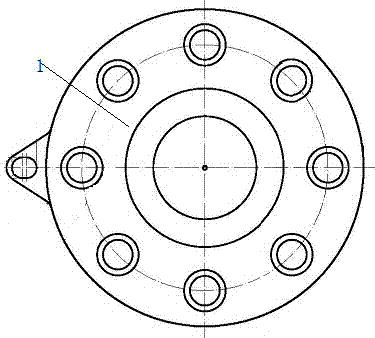

[0023] like figure 1 and figure 2 As shown, the elastic wheel of the present invention comprises a wheel bottom plate 1 and a wheel end plate 2; and a rubber 3 installed between the wheel bottom plate and the wheel end plate; the wheel bottom plate 1 and the wheel end plate 2 are all made of Q235 material Made; the rubber 3 is composed of natural rubber as the main material;

[0024] In yet another embodiment, the exposed metal of the wheel bottom plate 1 and the wheel end plate 2 is sprayed with a gray antirust paint layer.

[0025] In yet another embodiment, the wheel bottom plate 1 and the wheel end plate 2 are axially provided with arc-shaped concave-convex surfaces.

[0026] Wherein, the requirements of the rubber 3 are as follows: hardness 63±3°Sha, tensile strength ≥ 15Mpa, elongation at break ≥ 300%.

[0027] Wherein, its axial stiffness of described wheel is as follows:

[0028] Axially load 2.5mm at a loading speed of 1mm / min and then unload, preload twice in th...

Embodiment 2

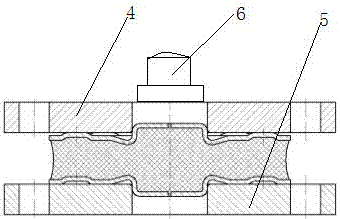

[0034] Randomly select two finished wheels and load them into image 3 On the jig shown, the test is divided into two times, each time a wheel is loaded on the test jig, and the stiffness is 10.5±20% kN / mm when the axial load is 2.5mm; the test results are as follows Figure 5 and Image 6 As shown, the axial stiffness of sample 1 is 11.16 kN / mm, and the axial stiffness of sample 2 is 10.10 kN / mm.

Embodiment 3

[0036] Randomly select two finished wheels and load them into Figure 4 On the jig shown, two samples are tested at the same time. When the distance between the two stress surfaces of the product is compressed to 32mm, the lateral load is 6.875kN, and the shear stiffness value is 1.125±30%kN / mm; the test results are as follows Figure 7 As shown, the shear stiffness is 1.255kN / mm.

[0037] In the elastic wheel of the present invention, the wheel bottom plate and the wheel end plate are made of Q235 material, its chemical composition can meet the requirements, and the rubber is mainly made of natural rubber. Standard test and calculation of shear stiffness to ensure that it can meet the application requirements.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com