Converter water-cooling furnace mouth and preparation process thereof

A preparation process and water-cooled furnace technology, which is applied in the manufacture of converters, etc., can solve problems such as the two ends of the water pipe being easily burned by high temperature, and the cast iron cracks at the mouth of the water-cooled furnace, so as to reduce the consumption, increase the heat transfer, avoid the scurrying effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

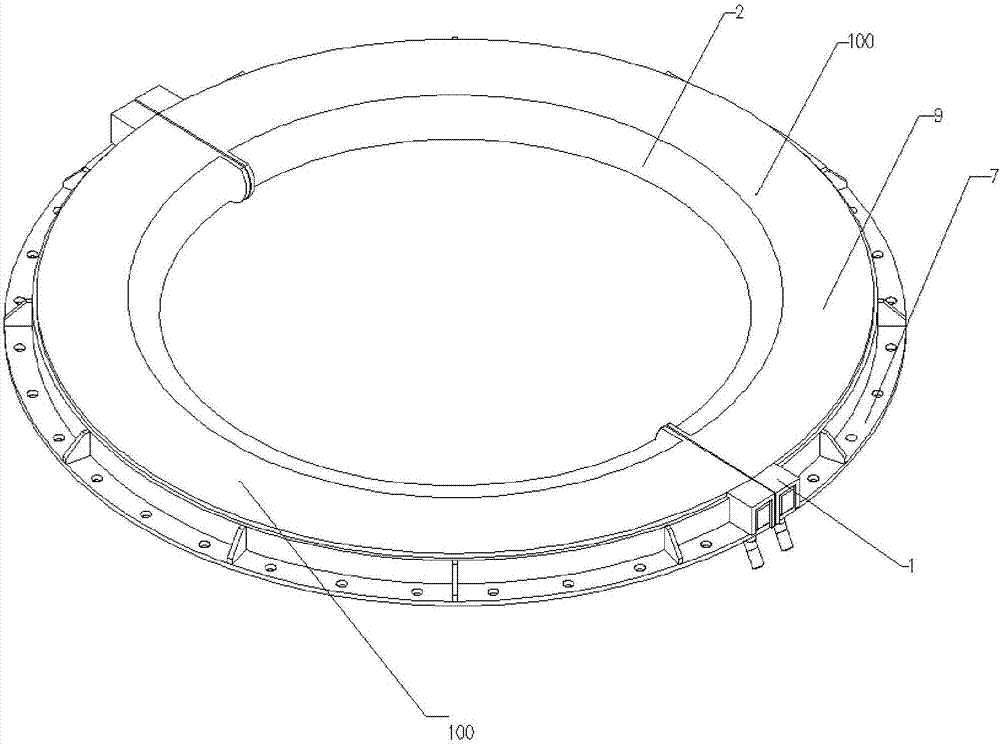

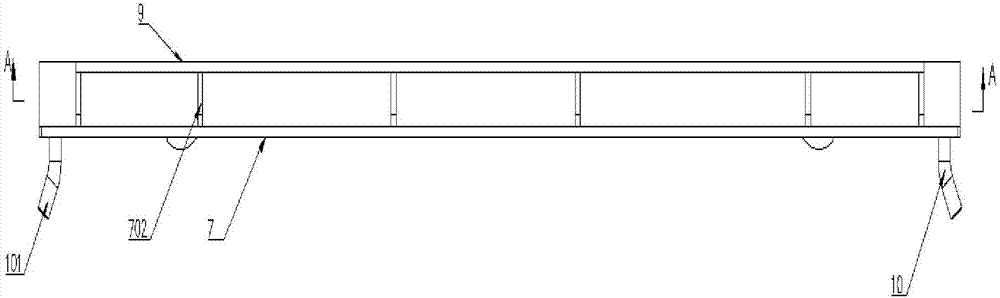

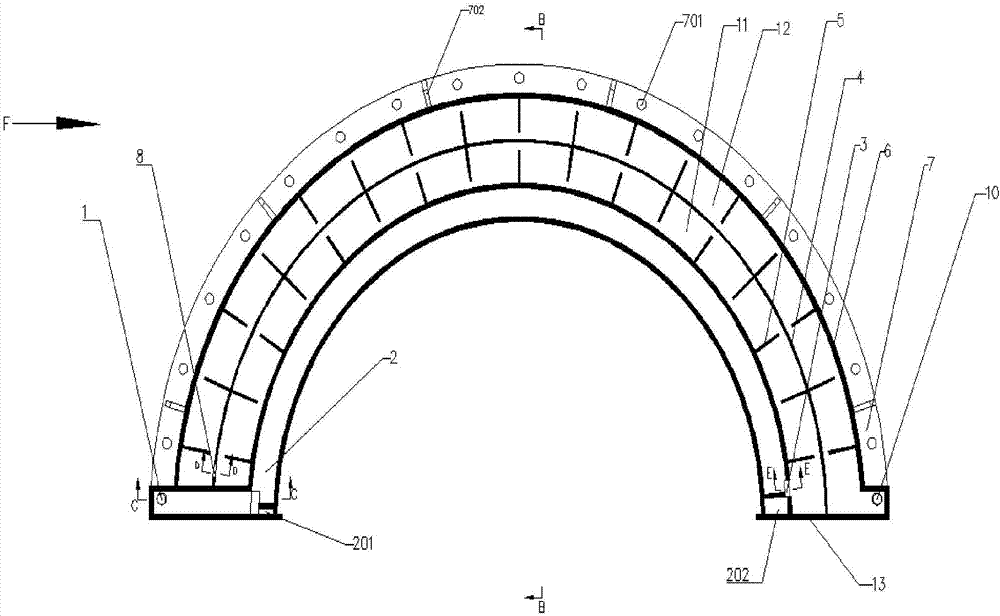

[0058] The technical solution of this embodiment is: a water-cooled furnace mouth of a converter, the converter water-cooled furnace mouth is composed of two semi-circular furnace mouth boxes 100 with the same structure, which are formed by annular splicing, and the semi-circular furnace mouth box 100 includes upper and lower The semicircular panel 9 and the semicircular bottom plate 7 and the water pipes 2 are fixedly connected with the inner side of the semicircular panel 9 and the inner side of the semicircular bottom plate 7; The first partition 4 and the second partition 6 are parallel to the water pipe 2, the first partition 4 and the water pipe 2 form a first water flow channel 11, and the first partition 4 and the second partition 6 form a second water flow channel 12, at least one of the first water flow channel (11) and the second water flow channel 12 is provided with a number of baffles 5, and the adjacent baffles 5 are staggered; the water pipe 2, the first water f...

Embodiment 2

[0061] On the basis of the first embodiment, the technical solution of this embodiment is as follows: the water inlet device 1 has a rectangular cavity structure; A water inlet pipe 101 is connected to the cavity structure, one side of the rectangular cavity structure is communicated with the water pipe 2, and a third water outlet 103 is opened at the communication place, and the other end of the water pipe 2 communicated with the rectangular cavity structure is provided with the water pipe 2. The first water outlet 3 communicated with the first water flow channel 11, the second water outlet 8 communicated with the second water flow channel 12 is opened at the other end of the first partition 4 and the water pipe 2. The other end of the second water flow channel 12 that communicates with the first remote water flow channel 11 is connected to the water outlet pipe 10 .

[0062] like image 3 , Image 6 As shown, the cooling water flows through the water pipe 2 from the third ...

Embodiment 3

[0064] On the basis of the second embodiment, the technical solution of this embodiment is as follows: the third water outlet 103 is provided with a first baffle group 102 along the radial direction of the cross-sectional circle of the water pipe 2, and the first baffle group 102 and the The ends of the adjacent water pipes 2 form a first cavity 201; the first water outlet 3 is provided with a second baffle group 301 along the radial direction of the cross-sectional circle of the water pipe 2, and the second baffle group 301 is adjacent to the The end of the water pipe 2 forms a second cavity 202 .

[0065] like image 3 , Image 6 and Figure 8 As shown, when the cooling water flows through the third water outlet 103, a small part of the water enters the first cavity 201, so as to avoid the phenomenon that the end of the water pipe 2 close to the first baffle group 102 is burnt out due to lack of water. ; When the cooling water flows through the first water outlet 3, a sma...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radian | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com