Approach channel retaining wall repairing structure and method

A technology for repairing structures and approach channels. It is applied in water conservancy projects, sea area projects, buildings, etc. It can solve problems such as collapse, potential safety hazards, and easy stress on straight sides, achieving the effect of small space and high timeliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

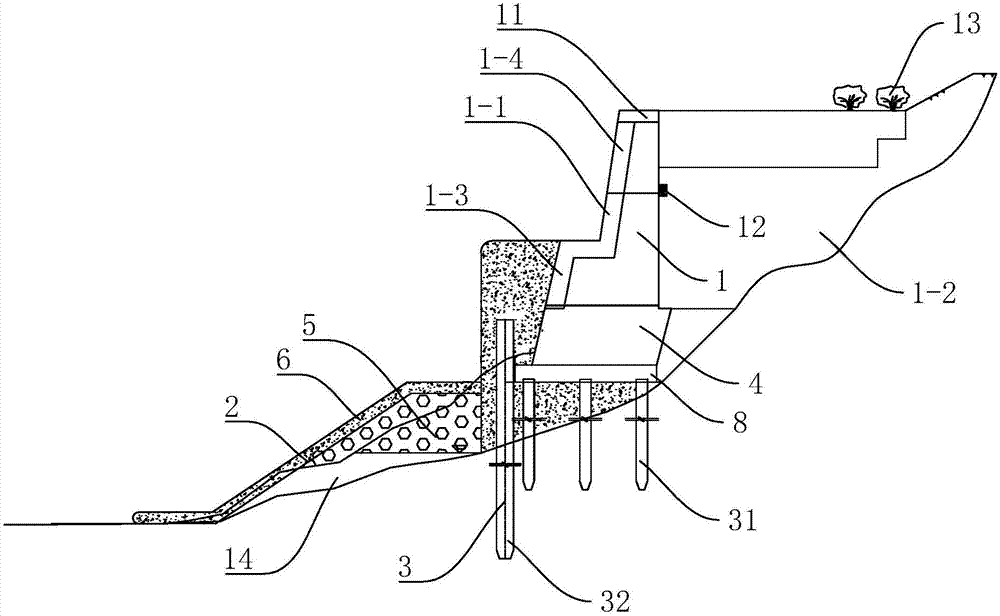

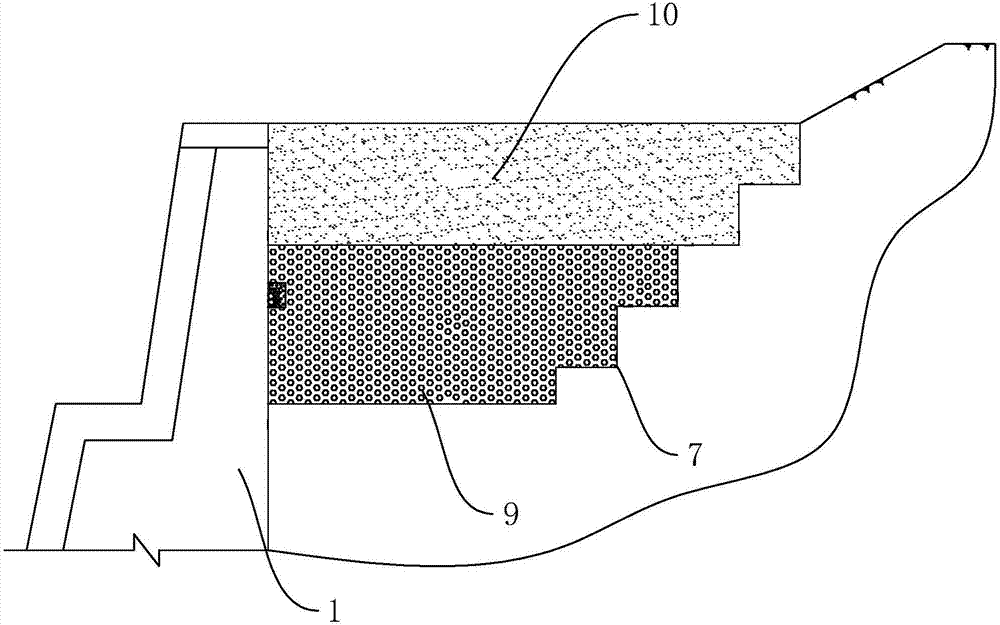

[0040] Embodiment 1: A kind of revetment repair structure of approach channel, such as figure 1 As shown, it includes a body of wall 1 vertically on the ground. The side of the body of wall 1 facing the water is the water-facing surface 1-1, and the side facing the ground is the back-water surface 1-2. Prefabricated square piles 3. Wherein, the prefabricated square piles 3 independent from the wall 1 are detachable piles 32 , and the prefabricated square piles 3 located below the wall 1 and fixedly connected with the wall 1 are fixed piles 31 . The length of detachable pile 32 is obviously greater than fixed pile 31, and the depth that detachable pile 32 stretches into the river bottom scour line is greater than the depth that fixed pile 31 stretches into the ground, and the end of detachable pile 32 away from the ground extends to body of wall 1 middle section. The facing surface 1-1 of the wall 1 is set in a ladder shape, the first step 1-3 is near the ground, the second st...

Embodiment 2

[0045] Embodiment 2: a method for repairing approach channel revetment, comprising the following steps:

[0046] Firstly, fill the soil on the side of the wall 1 facing the water, cover the original river bottom scour line, and the top of the filled soil presents an inclined surface, and the height gradually decreases from the 1 position close to the wall to the 1 position away from the wall.

[0047] Drive into the prefabricated square pile 3 on the side of the body of wall 1 facing the water area, where the prefabricated square pile 3 is a detachable pile 32 . The prefabricated square pile 3 is close to the body of wall 1 and is vertical to the ground, and the end of the prefabricated square pile 3 away from the ground is higher than the surface formed by throwing and filling the soil.

[0048] Concrete wall body 4 is poured at prefabricated square pile 3, the side of concrete wall body 4 facing the water area is set as a vertical surface, the top surface of concrete wall bo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com