Floor structure formed by prefabricated trough plates and construction method

A technology of grooved slabs and floor slabs, which is applied to floors, building components, building structures, etc., can solve problems such as poor durability, high quality floor slab structures, and complicated construction processes, so as to increase the shear resistance and reduce the difficulty of hoisting. The effect of simple hoisting construction process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

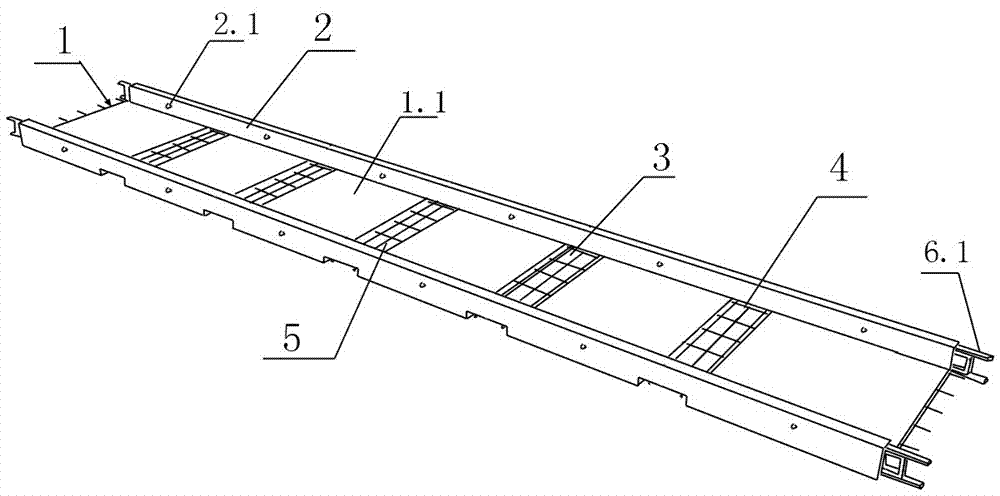

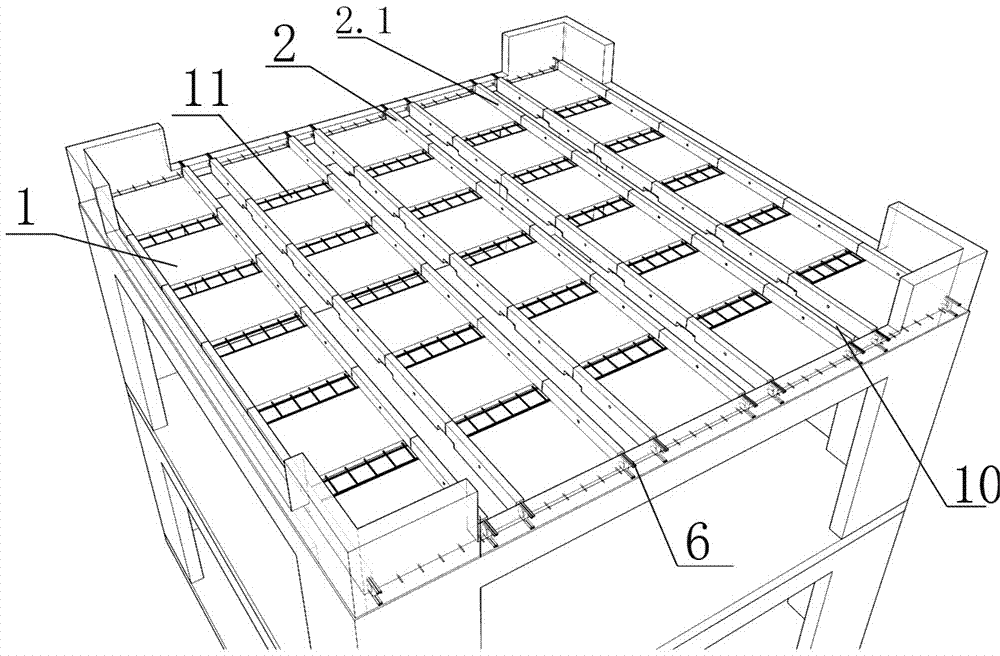

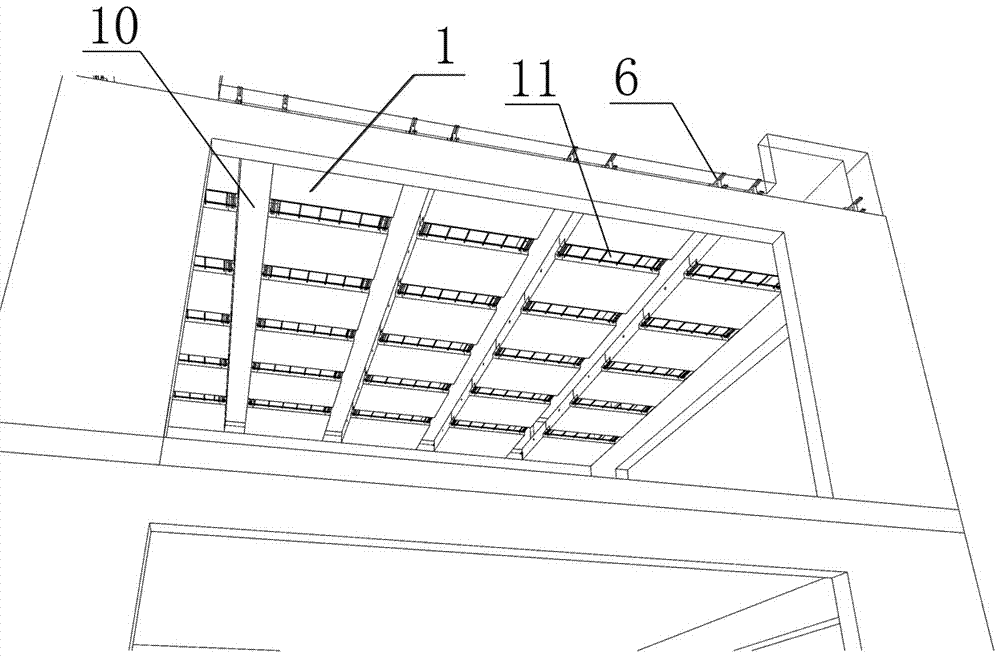

[0047] Such as Figure 6 Said, the floor structure formed by the prefabricated slab, the slab structure includes the prefabricated slab, the longitudinal rib beam 8 and the lightweight filling layer 9 filled in the prefabricated slab; the prefabricated slab has at least two , wherein the two ends of each prefabricated slab are erected on the building structure respectively; two adjacent prefabricated slabs are spaced apart from each other to form a post-cast belt 10 of the longitudinal rib beam; the position of the post-cast strip 10 of the longitudinal rib beam is generally long The longitudinal rib beam reinforcement 12 is configured and filled with concrete to form the longitudinal rib beam 8; the prefabricated channel plate is a reinforced concrete prefabricated channel member that includes the base plate 1 and the plate rib 2 and is integrally formed; the plate There are two ribs 2, which are arranged at intervals in parallel along the transverse direction of the base pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com