Contact fuse with redundant design of sensor

A sensor and redundant technology, applied in the field of trigger fuze, can solve the problems of undiscussed piezoelectric sensor generating detonation signal, unconsidered, etc., to achieve the effect of preventing misoperation, improving reliability and improving safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

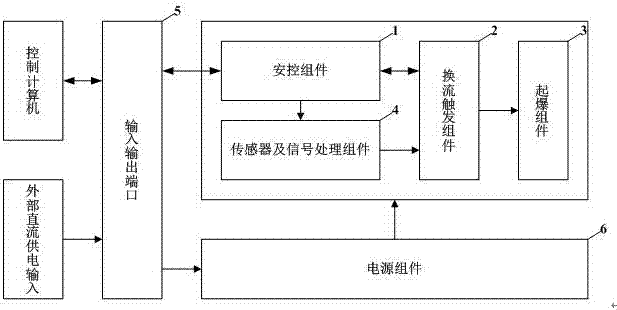

[0022] figure 1 It is a functional block diagram of a trigger fuze with sensor redundancy design in the present invention. From figure 1 It can be seen that the fuze includes a safety control component 1, a commutation trigger component 2, an initiating component 3, a sensor and signal processing component 4, an input and output port 5 and a power supply component 6, and is an all-electronic fuze.

[0023] The safety control component 1 of the fuze receives the control instruction of the control computer through the input and output port 5, and then the safety control component 1 executes the operation of disarming the insurance at all levels according to the control instruction, and further controls the generation and storage of detonation energy in the commutation trigger component 2; the fuze After complete release, the sensor senses the external mechanical environment conditions, and under certain conditions, the sensor and signal processing component 4 output a detonatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com