An anaerobic reaction control method and control system

An anaerobic reaction and control method technology, applied in the field of anaerobic reaction, can solve problems such as difficulty in determining reaction parameters and process parameters, inability to effectively adapt to variable and unstable anaerobic reactions, and inability to guarantee gas production efficiency, etc., to achieve guaranteed Maximize, improve safety, and ensure the effect of gas production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

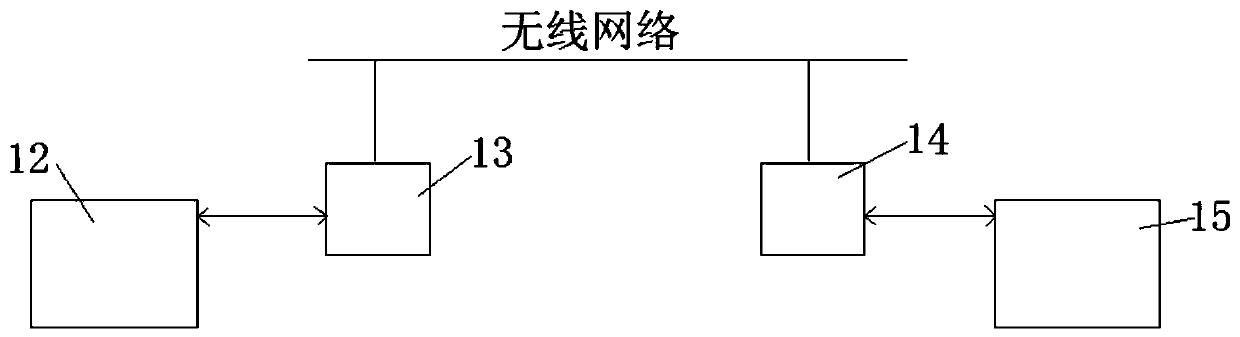

[0049] The method in this embodiment is applied in a remote controllable anaerobic reaction system, including the anaerobic reaction site arranged in various places and the remote data center server arranged in the control center, and the anaerobic reaction site is provided with an anaerobic The field equipment for the reaction, there are various sensors in the field equipment to obtain the working parameters of the field equipment, and various sensors are also installed in the reaction chamber to monitor the reaction process and obtain various parameters in the reaction. During the anaerobic reaction process, the on-site equipment is controlled by the on-site controller, and the on-site controller can also send various parameters to the remote data center server.

[0050] The embodiment of the present invention provides a kind of anaerobic reaction control method, is used for field controller, comprises

[0051] S1. Obtain the on-site operating parameters, regional informatio...

Embodiment 2

[0058] An embodiment of the present invention provides an anaerobic reaction control method for a remote data center server, including

[0059] S1. Receive on-site operating parameters, regional information and material information sent by the on-site controller, the on-site controller can be a PLC system;

[0060] S2. Comparing the on-site operating parameters, regional information and material information with the target data in the pre-established theoretical model of anaerobic reaction to obtain the target parameters required by the on-site controller. The theoretical model of anaerobic reaction is based on Different geographical information and material information are used to control the on-site operating parameters to conduct anaerobic reaction tests, and the test results are statistically analyzed. The target parameters include process parameters and / or operating parameters;

[0061] S3. Send the target parameter to the site controller.

[0062] According to the anaer...

Embodiment 3

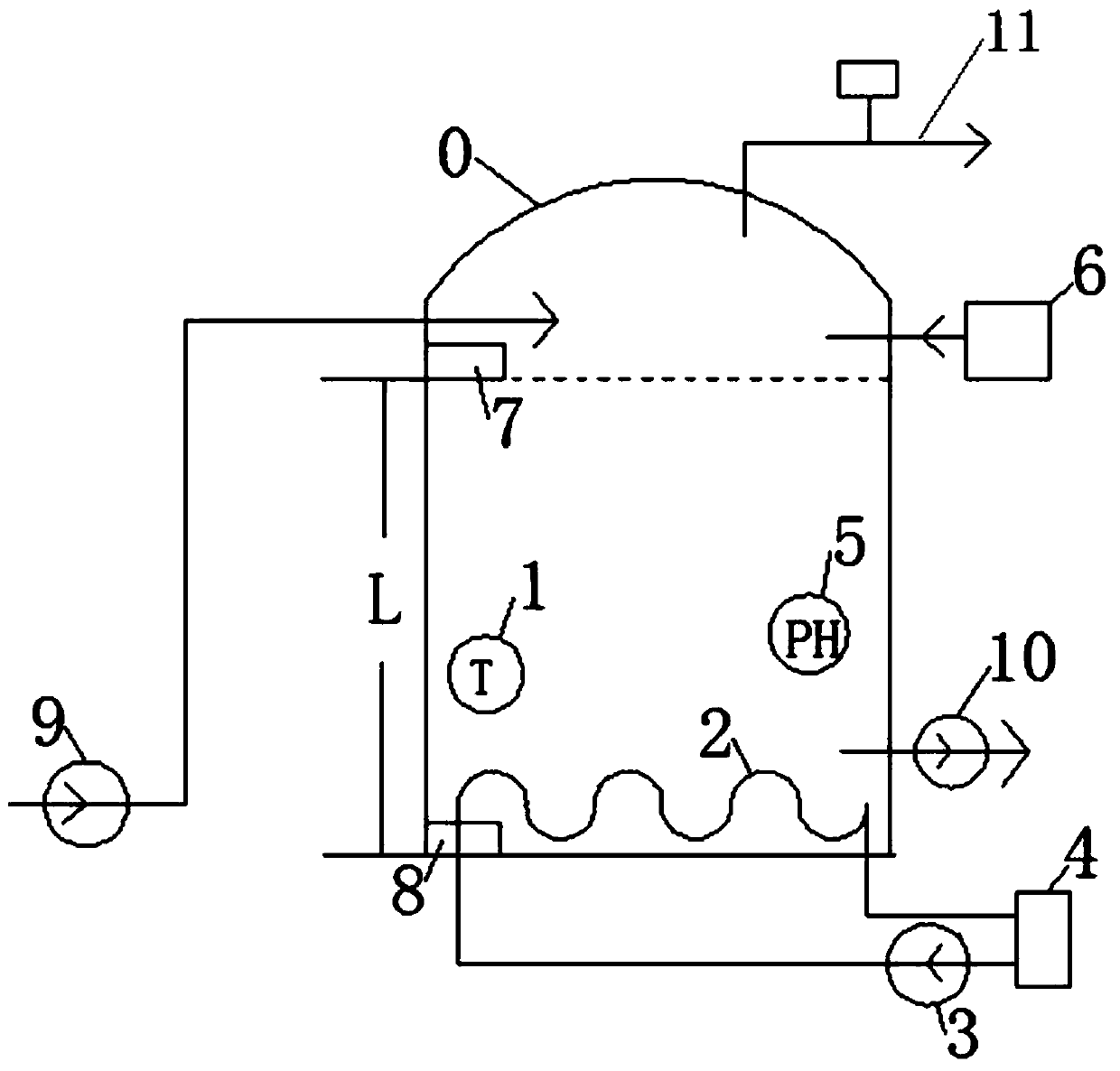

[0066] The embodiment of the present invention provides an anaerobic reaction control system for field controller 12, such as figure 1 and 2 As shown, it includes an acquisition module, which is used to acquire on-site operating parameters, regional information and material information of anaerobic reactions. The on-site parameters include process parameters and / or operating parameters, as optional, such as figure 1 As shown, the acquisition module includes a temperature transmitter 1, a pressure transmitter, a pH transmitter 5, a flow transmitter, a liquid level transmitter and an oxygen content detector. More specifically, there are two pressure transmitters, namely the first pressure transmitter 7 and the second pressure transmitter 8, which are respectively arranged at the upper material liquid level and the bottom of the anaerobic reaction device 0, so as to measure Knowing the pressure difference between the two places, the liquid level height L of the material in the a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com