SCR sulfur poisoning degree determination method and device, diesel vehicle and medium

A determination method and technology of sulfur poisoning, applied in the direction of muffler device, exhaust device, electronic control of exhaust gas treatment device, etc., can solve the problems of pollution, excessive emission, weakening of passive regeneration effect, etc., to ensure the effect of system performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

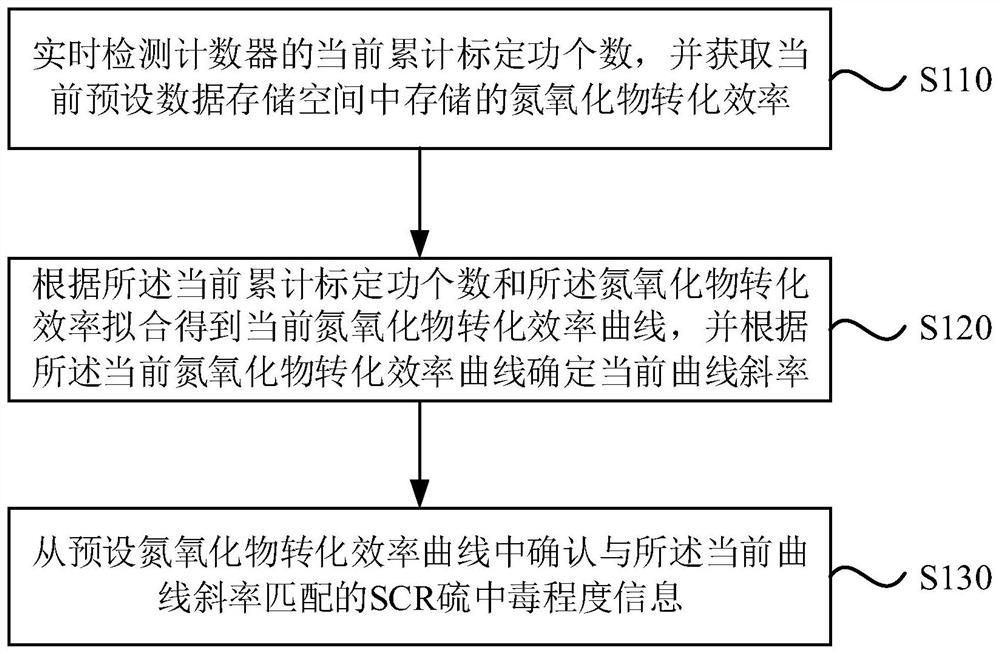

[0048] figure 1It is a flowchart of a method for determining the degree of SCR sulfur poisoning provided by Embodiment 1 of the present invention. This embodiment can be applied to identify the degree of SCR sulfur poisoning to remind the driver of the situation in which the performance of the aftertreatment system is restored in time after desulfurization. The SCR sulfur poisoning degree is determined The method can be executed by an SCR sulfur poisoning degree determining device, and the SCR sulfur poisoning degree determining device can be implemented in the form of software and / or hardware. The method for determining the degree of SCR sulfur poisoning specifically includes the following steps:

[0049] S110. Real-time detection of the current cumulative calibration work number of the counter, and obtaining the nitrogen oxide conversion efficiency stored in the current preset data storage space.

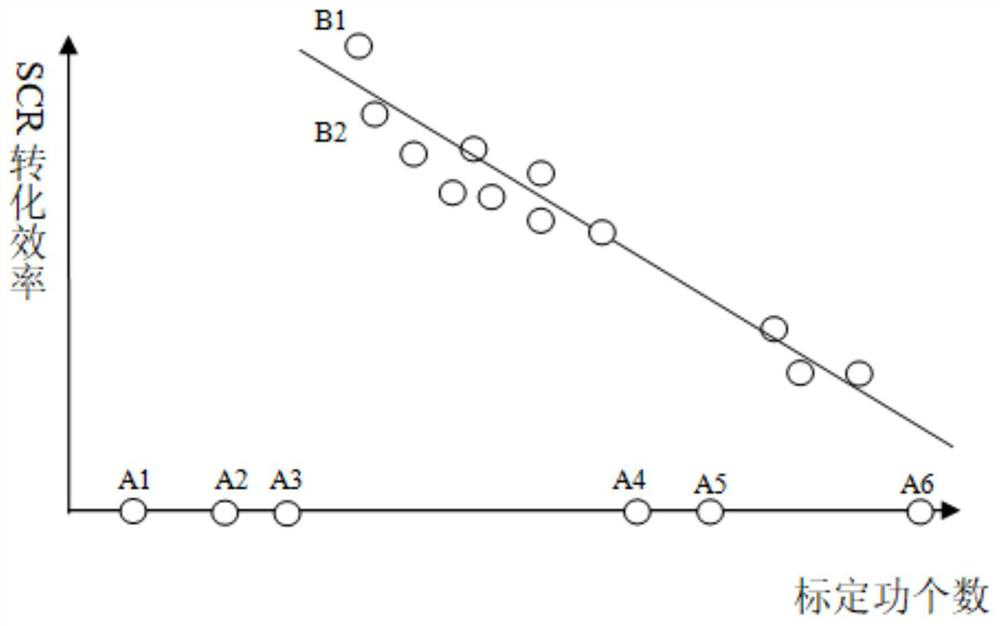

[0050] Wherein, the accumulative calibrated work is obtained by accumulating...

Embodiment 2

[0076] Figure 5 A flow chart of a method for determining the degree of SCR sulfur poisoning provided by Embodiment 2 of the present invention, Image 6 It is a structural block diagram of the method for determining the degree of SCR sulfur poisoning provided by the embodiment of the present invention. This embodiment is optimized on the basis of the above-mentioned embodiments.

[0077] Correspondingly, the method in this embodiment specifically includes:

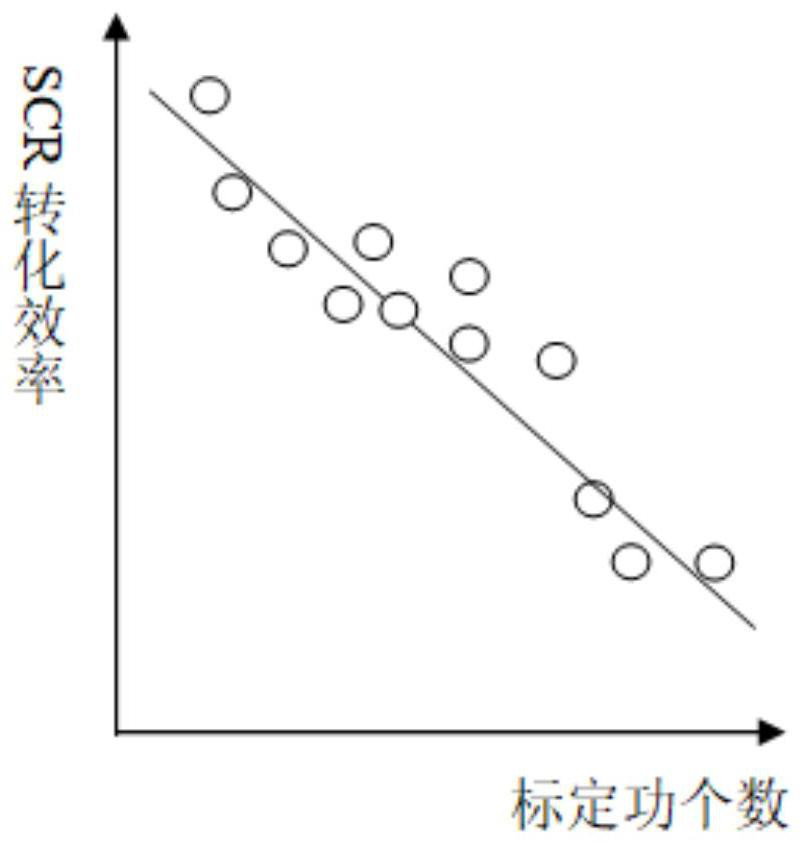

[0078] S510. Generate a preset nitrogen oxide conversion efficiency curve, the preset nitrogen oxide conversion efficiency curve includes SCR normal deterioration conversion efficiency cut-off curve, mild sulfur poisoning conversion efficiency cut-off curve, moderate sulfur poisoning conversion efficiency cut-off curve, and severe sulfur poisoning conversion efficiency cut-off curve. Sulfur poisoning conversion efficiency cut-off curve.

[0079] Specifically, X0, X1, X2, and X3 diesel oils with increasing sulfur content ...

Embodiment 3

[0100] Figure 7 The structure diagram of an SCR sulfur poisoning degree determination device provided by Embodiment 3 of the present invention, this embodiment can be applied to identify the SCR sulfur poisoning degree to remind the driver to desulfurize in time to restore the performance of the aftertreatment system.

[0101] like Figure 7 As shown, the SCR sulfur poisoning degree determination device includes: a nitrogen oxide conversion efficiency acquisition module 710, a current curve slope determination module 720 and a sulfur poisoning degree information confirmation module 730, wherein:

[0102] The nitrogen oxide conversion efficiency acquisition module 710 is used to detect in real time the current cumulative calibration work number of the counter, and obtain the nitrogen oxide conversion efficiency stored in the current preset data storage space;

[0103] The current curve slope determination module 720 is used to obtain the current nitrogen oxide conversion effi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com