Reinforced condenser rubber ball cleaning equipment

A condenser and enhanced technology, which is applied in the field of enhanced condenser rubber ball cleaning equipment, can solve the problems of inability to recover rubber balls, cleaning balls passing through, and complicated equipment design, and is suitable for comprehensive promotion and application, recycling The process is convenient and fast, and the structural design is simple and novel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

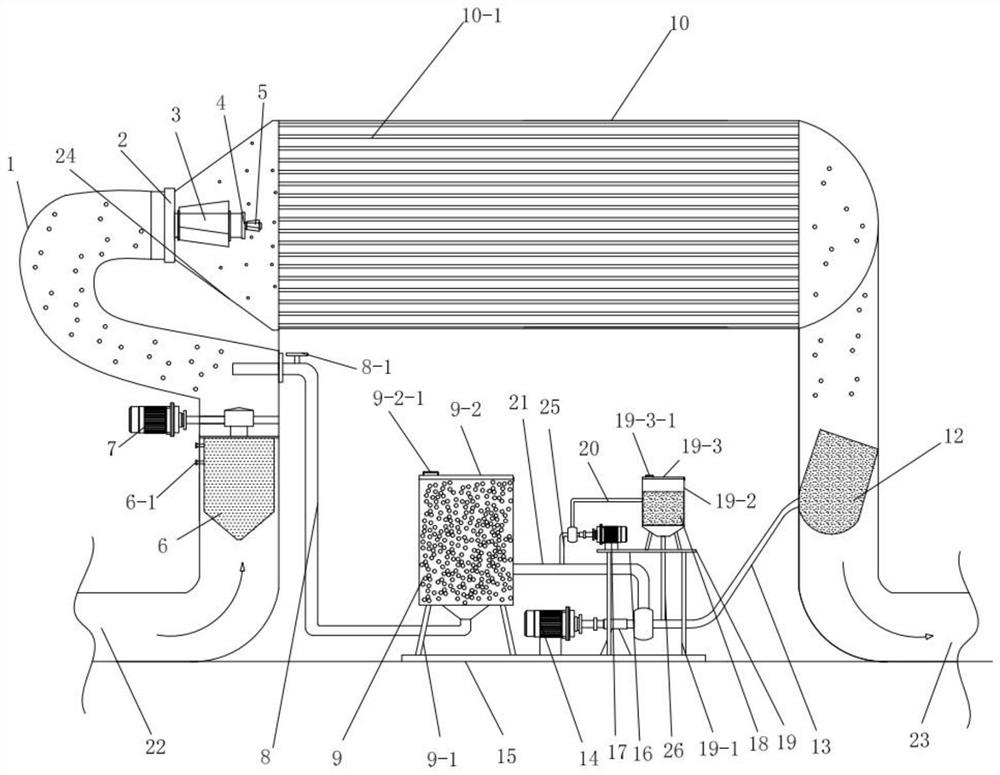

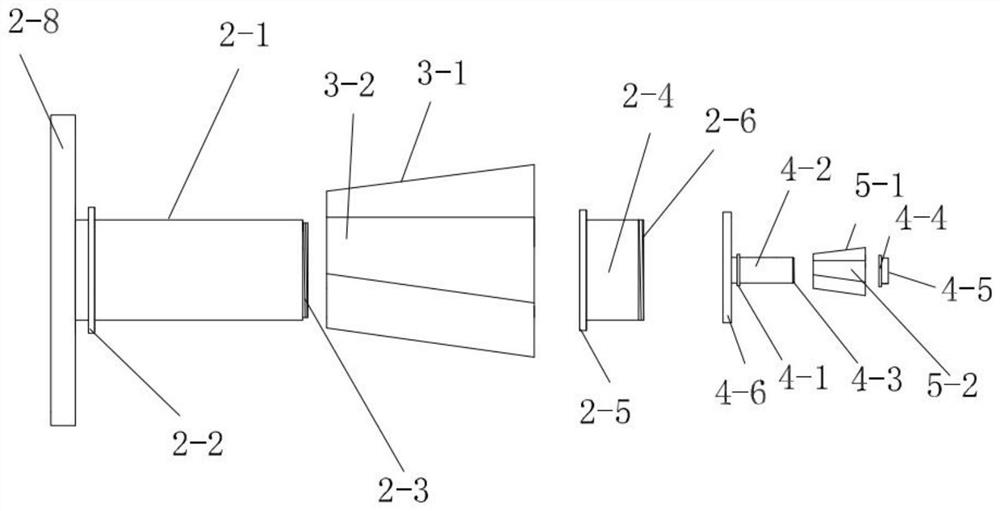

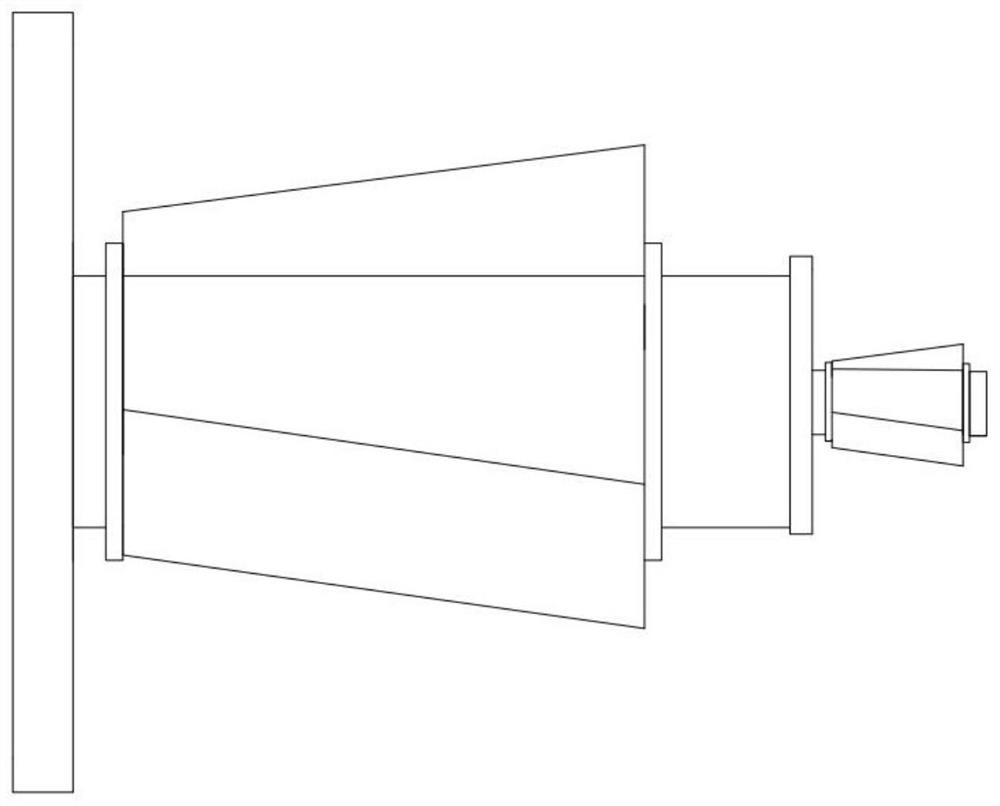

[0021] Such as Figure 1-Figure 8 Shown:

[0022] An enhanced condenser rubber ball cleaning device, comprising a base 15, a rubber ball delivery pump 14, a pipeline 13, a pipeline 2 8, a pipeline 3 21, a ball collecting net 12, a ball loading chamber 9 and a valve 8-1, glue The ball delivery pump 14 is installed on the base 15, and the below of the ball loading chamber 9 is provided with a fixed mount one 9-1, and the fixed mount one 9-1 is installed on the base 15, and the valve 8-1 is installed on the pipeline two 8, and the pipeline two One end of 8 is connected with water inlet pipe 22, the other end of pipeline 2 8 is connected with the bottom of ball-filling chamber 9, one end of pipeline 3 21 is connected with ball-filling chamber 9, and the other end of pipeline 3 21 is connected with rubber ball delivery pump 14 is connected, and one end of pipeline one 13 is connected with rubber ball conveying pump 14, and the other end of pipeline one 13 is connected with ball co...

Embodiment 2

[0025] Such as Figure 1-Figure 8 Shown:

[0026] An enhanced condenser rubber ball cleaning device, comprising a base 15, a rubber ball delivery pump 14, a pipeline 13, a pipeline 2 8, a pipeline 3 21, a ball collecting net 12, a ball loading chamber 9 and a valve 8-1, glue The ball delivery pump 14 is installed on the base 15, and the below of the ball loading chamber 9 is provided with a fixed mount one 9-1, and the fixed mount one 9-1 is installed on the base 15, and the valve 8-1 is installed on the pipeline two 8, and the pipeline two One end of 8 is connected with water inlet pipe 22, the other end of pipeline 2 8 is connected with the bottom of ball-filling chamber 9, one end of pipeline 3 21 is connected with ball-filling chamber 9, and the other end of pipeline 3 21 is connected with rubber ball delivery pump 14 is connected, and one end of pipeline one 13 is connected with rubber ball conveying pump 14, and the other end of pipeline one 13 is connected with ball co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com