Industrial control computer heat dissipation device

A heat dissipation device and industrial control technology, which is applied in computing, instruments, electrical digital data processing, etc., can solve the problems of easy ash falling, the main engine cannot effectively dissipate heat, etc., and achieve the effect of labor saving and convenient placement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

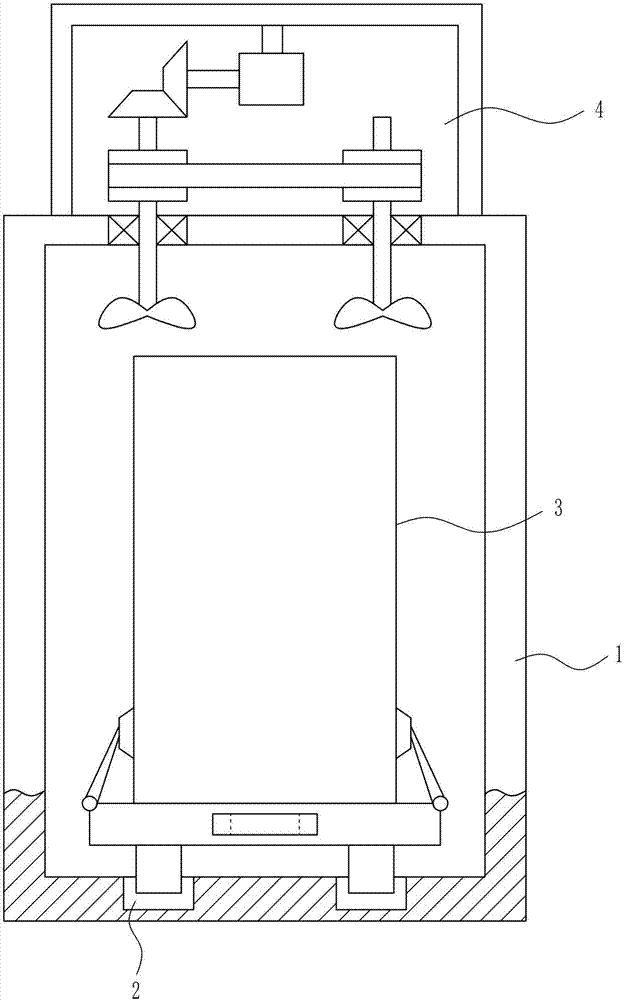

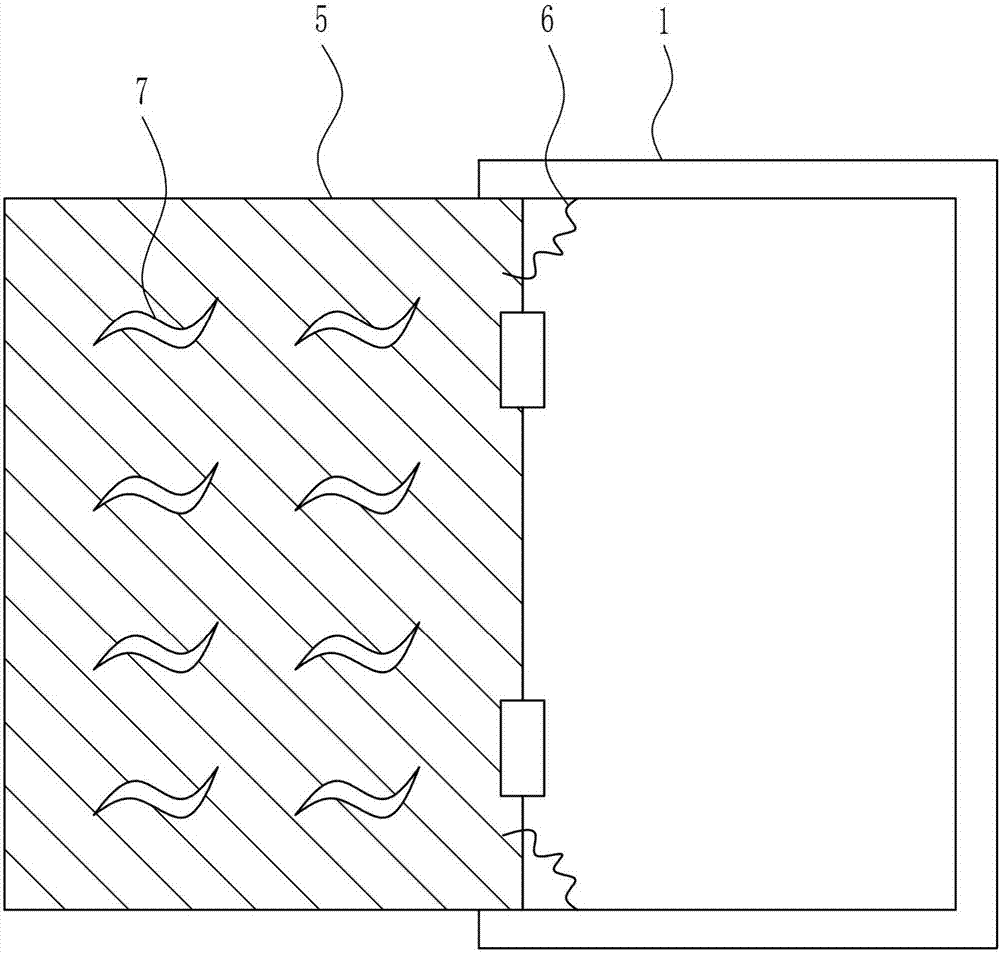

[0033] A computer cooling device for industrial control, such as Figure 1-6 As shown, it includes a placement box 1, a moving mechanism 2, a cooling mechanism 4, a door 5 and a first spring 6. The left side of the front wall is connected with a box door 5 by means of a hinge connection, and the first spring 6 is symmetrically connected between the inside of the box door 5 and the inside of the storage box 1, and S-shaped holes 7 are evenly arranged on the box door 5 .

Embodiment 2

[0035] A computer cooling device for industrial control, such as Figure 1-6As shown, it includes a placement box 1, a moving mechanism 2, a cooling mechanism 4, a door 5 and a first spring 6. The left side of the front wall is connected with a box door 5 by means of a hinge connection, and the first spring 6 is symmetrically connected between the inside of the box door 5 and the inside of the storage box 1, and S-shaped holes 7 are evenly arranged on the box door 5 .

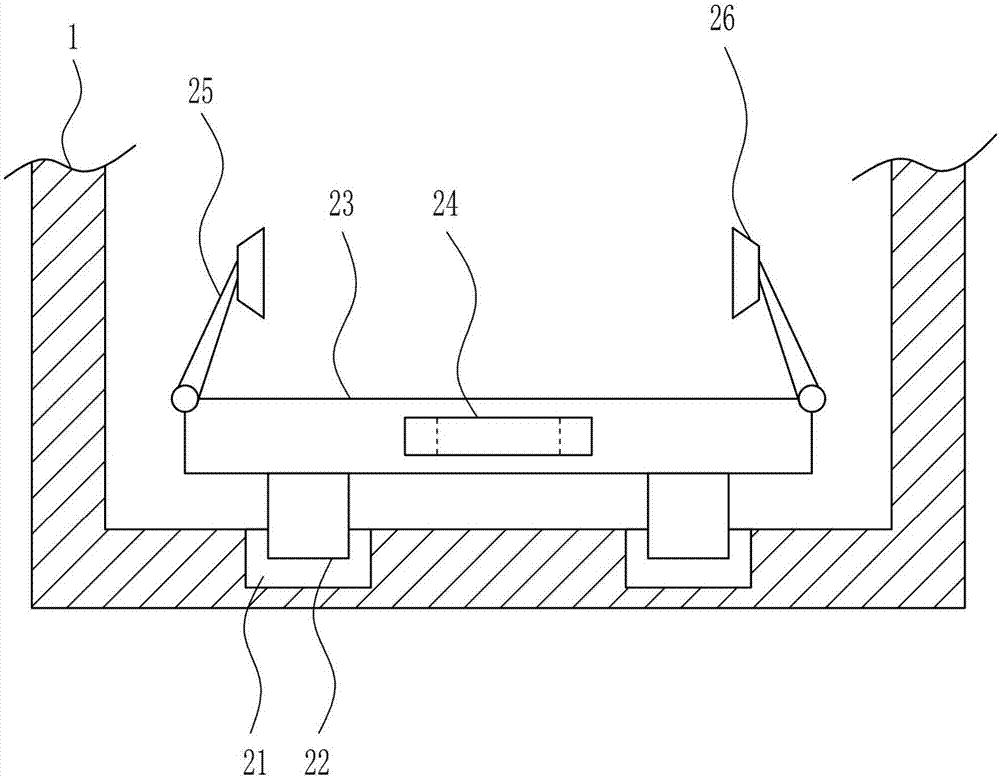

[0036] The moving mechanism 2 includes a slide rail 21, a slide block 22, a placement plate 23, a handle 24, a first rotating rod 25 and a suction cup 26, and the bottom of the placement box 1 is symmetrically connected with a slide rail 21, and the slide rail 21 is slidably connected with a slide rail. Block 22, slide rail 21 cooperates with slide block 22, slide block 22 top is connected with place plate 23, place plate 23 front wall middle part is connected with handle 24, and place plate 23 left and right s...

Embodiment 3

[0038] A computer cooling device for industrial control, such as Figure 1-6 As shown, it includes a placement box 1, a moving mechanism 2, a cooling mechanism 4, a door 5 and a first spring 6. The left side of the front wall is connected with a box door 5 by means of a hinge connection, and the first spring 6 is symmetrically connected between the inside of the box door 5 and the inside of the storage box 1, and S-shaped holes 7 are evenly arranged on the box door 5 .

[0039] The moving mechanism 2 includes a slide rail 21, a slide block 22, a placement plate 23, a handle 24, a first rotating rod 25 and a suction cup 26, and the bottom of the placement box 1 is symmetrically connected with a slide rail 21, and the slide rail 21 is slidably connected with a slide rail. Block 22, slide rail 21 cooperates with slide block 22, slide block 22 top is connected with place plate 23, place plate 23 front wall middle part is connected with handle 24, and place plate 23 left and right ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com