Welding cleaver and preparation method thereof

A rivet and knife tip technology is applied in the field of welding rivets and their preparation, which can solve the problems of shortening the life of the ribbing knife, increasing energy consumption, and metal residues, reducing energy loss, improving transmission efficiency, and simplifying processing conditions. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

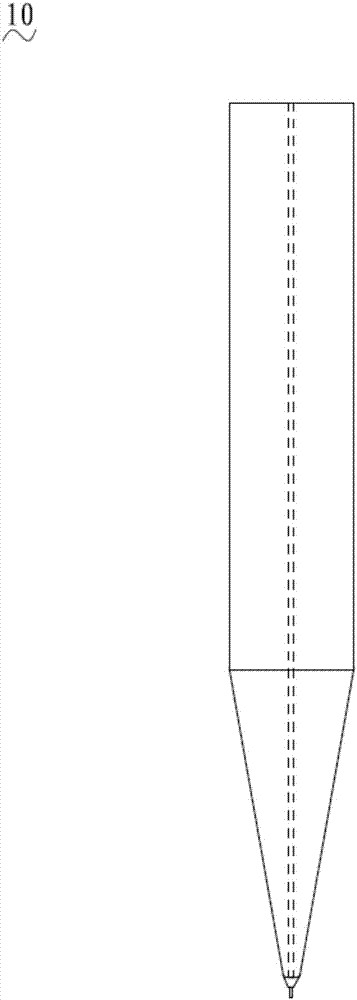

[0037] see Figure 4 to Figure 6 , the welding capillary 40 of the first embodiment of the present invention includes a connecting portion 41 and a knife mouth portion 42 connecting the connecting portion 41, the middle part of the welding capillary 40 is provided with a passage 43, and the passage 43 extends from the top of the connecting portion 41 To the bottom of the knife mouth 42 , the passage 43 communicates with the connecting portion 41 and the center of the knife mouth 42 , so that the ultrasonic waves can be transmitted from the top of the connecting portion 41 to the bottom of the knife mouth 42 .

[0038] Further, the connecting portion 41 is cylindrical for connecting the ultrasonic transducer, and the mouth portion 42 is conical.

[0039] In this embodiment, passage 43 includes cylindrical groove 411 and tapered groove 412 connected with cylindrical groove 411. The diameter of cylindrical groove 411 is greater than the diameter of one end of tapered groove 412 c...

Embodiment 2

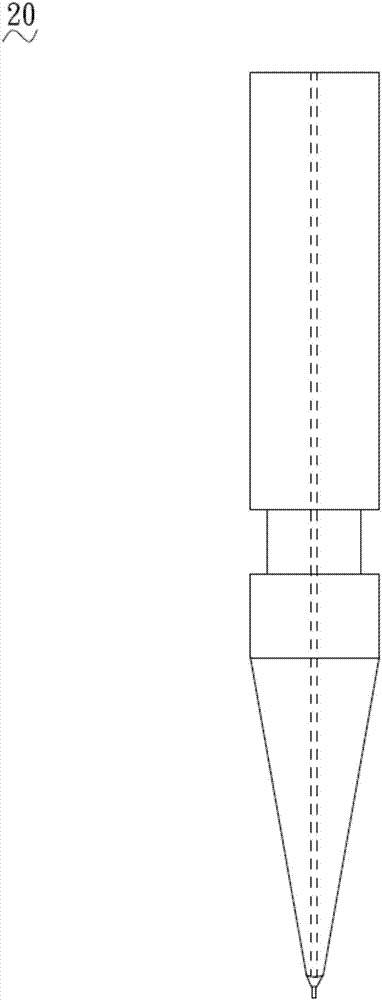

[0049] see Figure 4 and Figure 7 The external structure of the connecting portion 41 and the tip portion 42 of the welding capillary 420 of this embodiment is the same as that of the welding capillary 40 of the first embodiment. The difference is that the passageway 43 of the present embodiment includes a cylindrical groove 421 and a tapered groove 422 connected to the cylindrical groove 421. The diameter of the cylindrical groove 421 is equal to the diameter of one end of the tapered groove 422 connecting the cylindrical groove 421, and the cylindrical groove 421 is connected to the cylindrical groove 421. The tapered groove 422 is coupled and connected, and the connection is an arc surface. The passage 43 extends from the top end of the connection portion 41 to the bottom end of the knife mouth portion 42 , and the passage 43 communicates with the connection portion 41 and the knife mouth portion 42 .

[0050] Further, the height difference h between the connection point...

Embodiment 3

[0057] see Figure 4 and 8 The outer structure of the connection portion 41 and the tip portion 42 of the welding capillary 430 of this embodiment is the same as that of the welding capillary 40 of the first embodiment. The difference lies in that the passage 43 of the welding capillary 430 in this embodiment communicates with the center of the connecting portion 41 and the tip portion 42 , and the passage 43 is in a continuous tapered structure. The passage 43 extends from the top end of the connecting portion 41 to the bottom end of the knife mouth portion 42 .

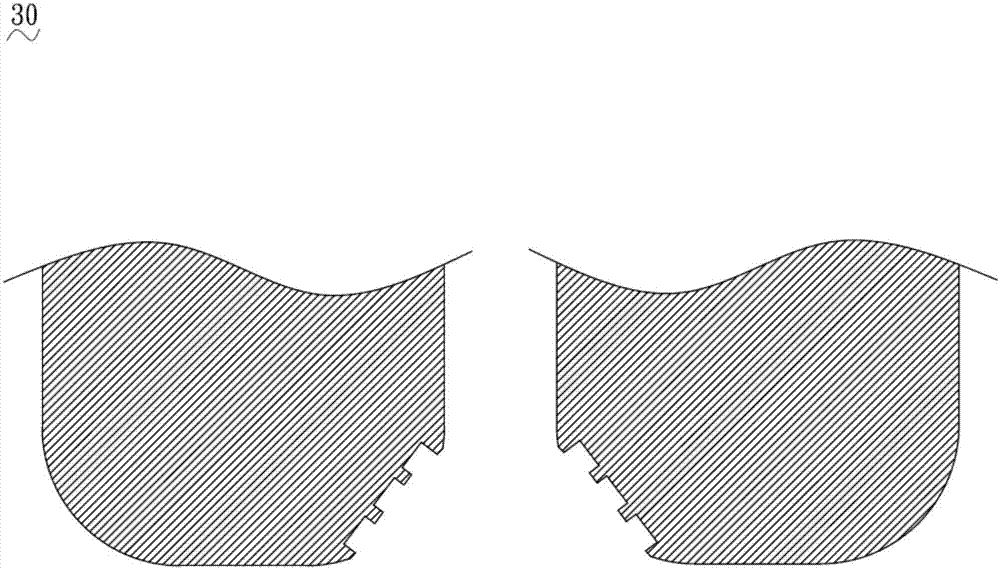

[0058] The above-mentioned welding chopper 430 is prepared by dry pressing, and the dry pressing equipment 50 is as follows: Figure 8 Shown, preparation method comprises the following steps:

[0059] Preparatory stage: pass the setting wire 51 sequentially through the clamping mechanism 52, the pressing plate 53, the punch 54, the mold cavity 56 formed by the docking of the left half mold 55a and the right half ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com