Lithium battery cell outer membrane hot melting mechanism

A lithium battery and hot-melt technology, applied in non-aqueous electrolyte battery, electrolyte battery manufacturing, sustainable manufacturing/processing, etc., can solve the problems of large space occupation and unsmooth connection between upstream and downstream processes, and achieve small footprint , compact structure, simple and reasonable structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] The present invention will be further described below in conjunction with accompanying drawing:

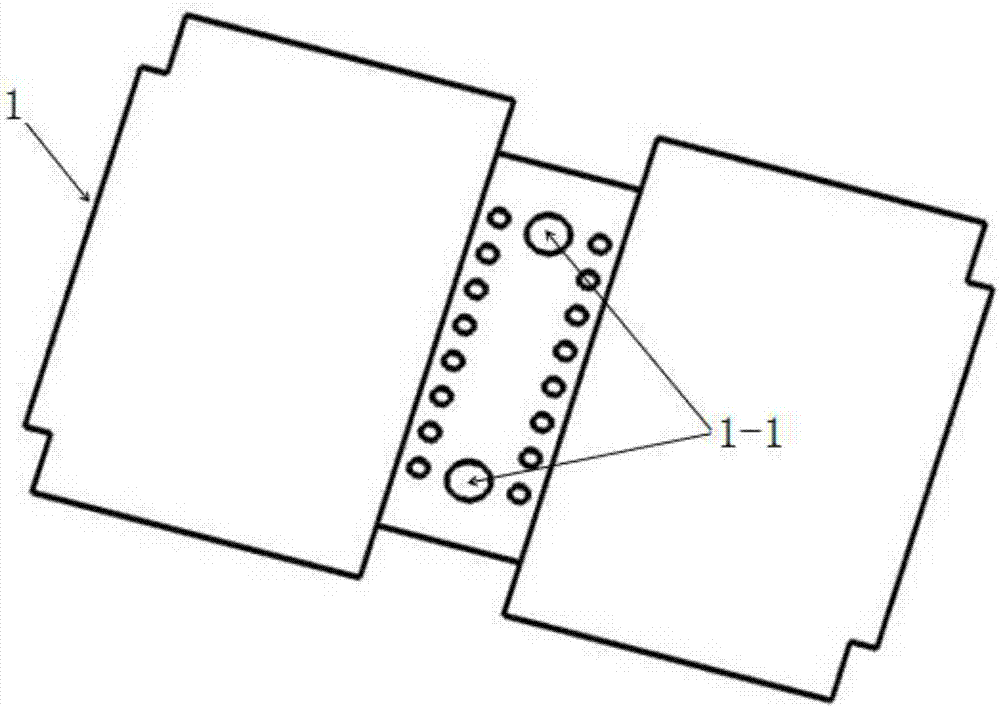

[0042] Such as figure 1 Shown is a schematic diagram of the structure of the insulating film 1, in which a positioning hole 1-1 is opened at the middle connection.

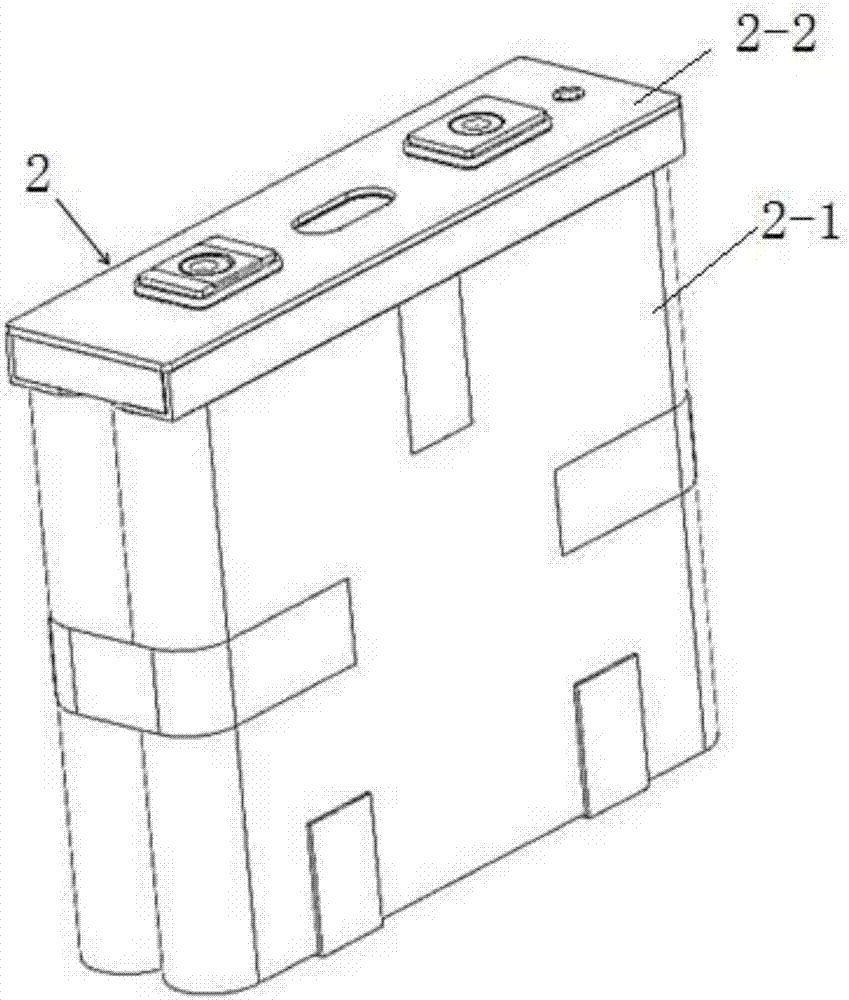

[0043] Such as figure 2 Shown is a schematic structural view of the battery cell 2 coated with incoming material, and the tabs of the battery body 2-1 are welded together with the cover plate 2-2.

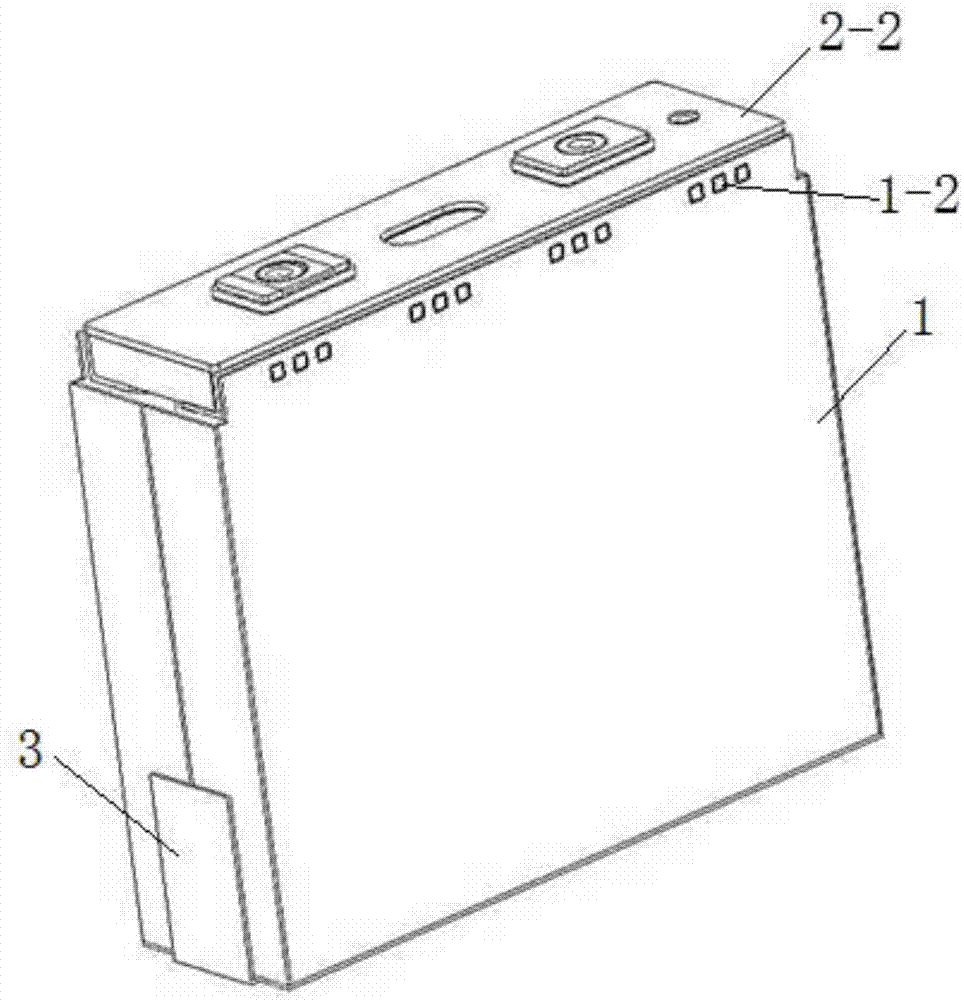

[0044] Such as image 3 Shown is a schematic diagram of the structure of the battery core after hot-melt coating. The insulating film 1 is coated on the outside of the battery core 2. After hot-melting, a hot-melt welding mark 1-2 is formed on the cover plate 2-2. The insulating film 1 The two sides are fixed by adhesive tape 3.

[0045] Such as Figure 4 As shown, a lithium battery cell outer membrane hot-melt mechanism includes a cell feeding mechanism 5 and a discharging mechanism 9 arranged in a straight l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com