Variable coefficient underclocking model prediction direct power control method and device

A model prediction and power control technology, which is applied in the direction of output power conversion devices, circuit devices, AC power input conversion to DC power output, etc., can solve the problems of inability to adapt to system changes in real time, unstable power tracking, and increased system complexity, etc. problem, to achieve the effect of reducing the number of switching actions, reducing the switching frequency, and increasing the pertinence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

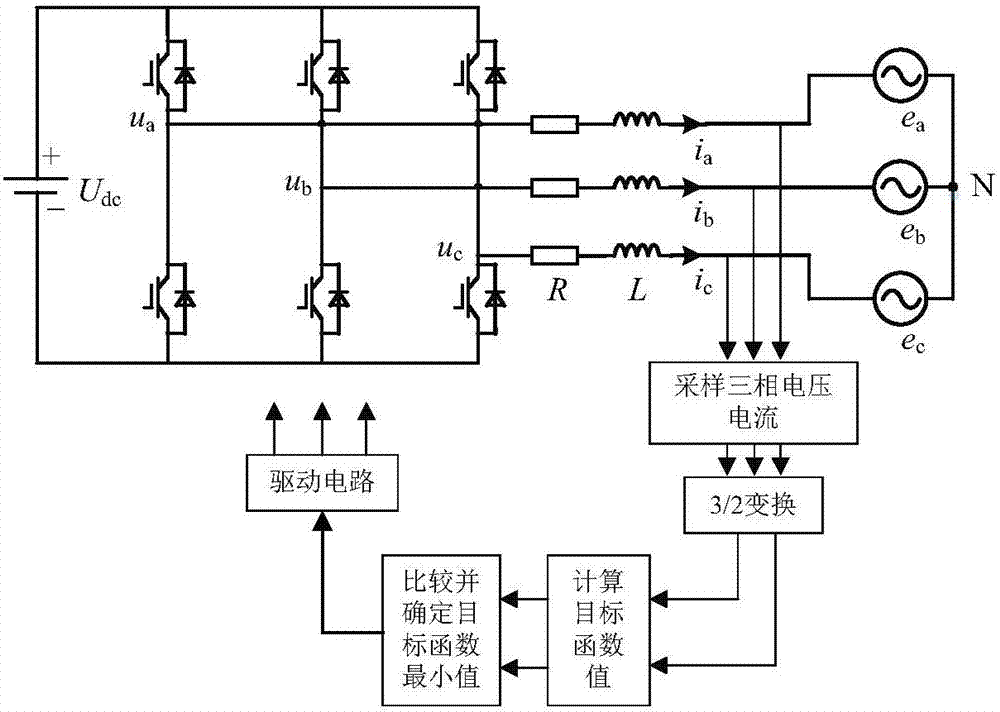

[0047] In order to make the object, technical solution and advantages of the present invention clearer, the present invention will be described in further detail below in conjunction with specific embodiments and with reference to the accompanying drawings.

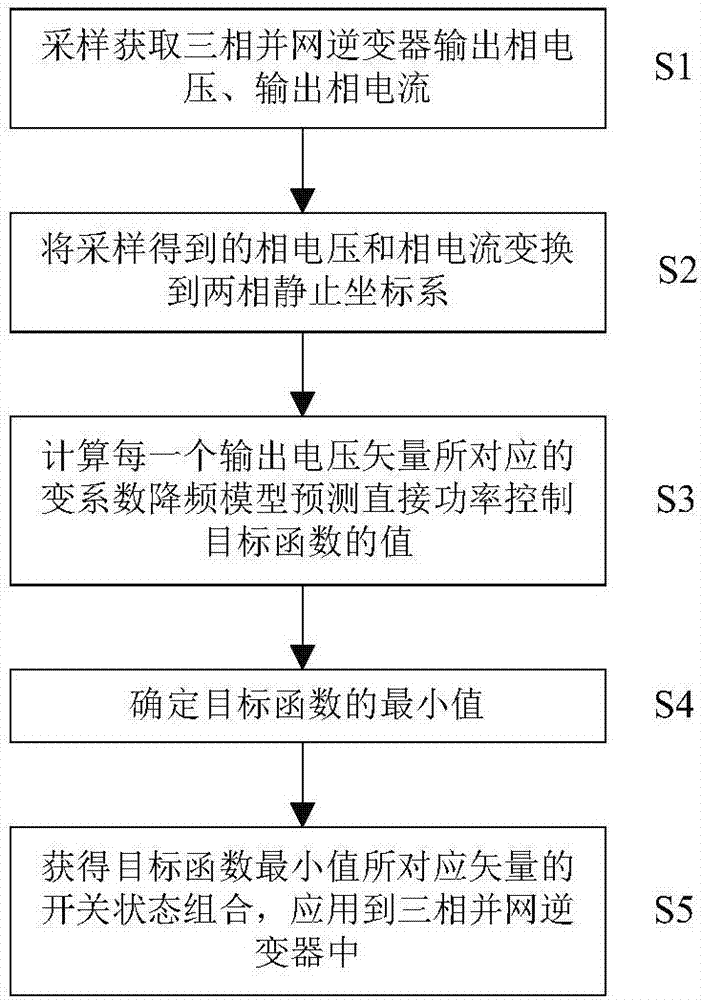

[0048] Refer to attached figure 1 A schematic flow chart of an embodiment of the variable coefficient frequency reduction model prediction direct power control method provided by the present invention;

[0049] The variable coefficient frequency reduction model predicts the direct power control method, including:

[0050] S1. Obtain the output phase voltage e of the three-phase grid-connected inverter a 、e b 、e c and output phase current i a i b i c ;

[0051] S2, the sampled output phase voltage e a 、e b 、e c and output phase current i a i b i c , after 3 / 2 transformation, the voltage signal e in the two-phase stationary coordinate system is obtained α 、e β and the current signal i α i β ;

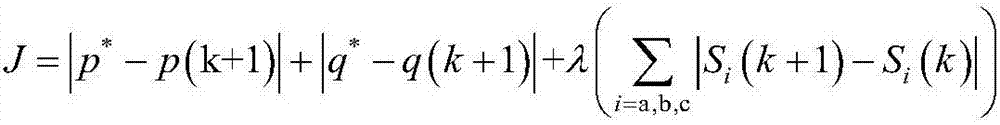

[0052] S3. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com