Inverter control unit and air conditioner

A control device and inverter technology, applied in refrigerators, control systems, vector control systems, etc., can solve problems such as the inability to reduce the cost of microcomputers with AD conversion units, and achieve the effect of cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

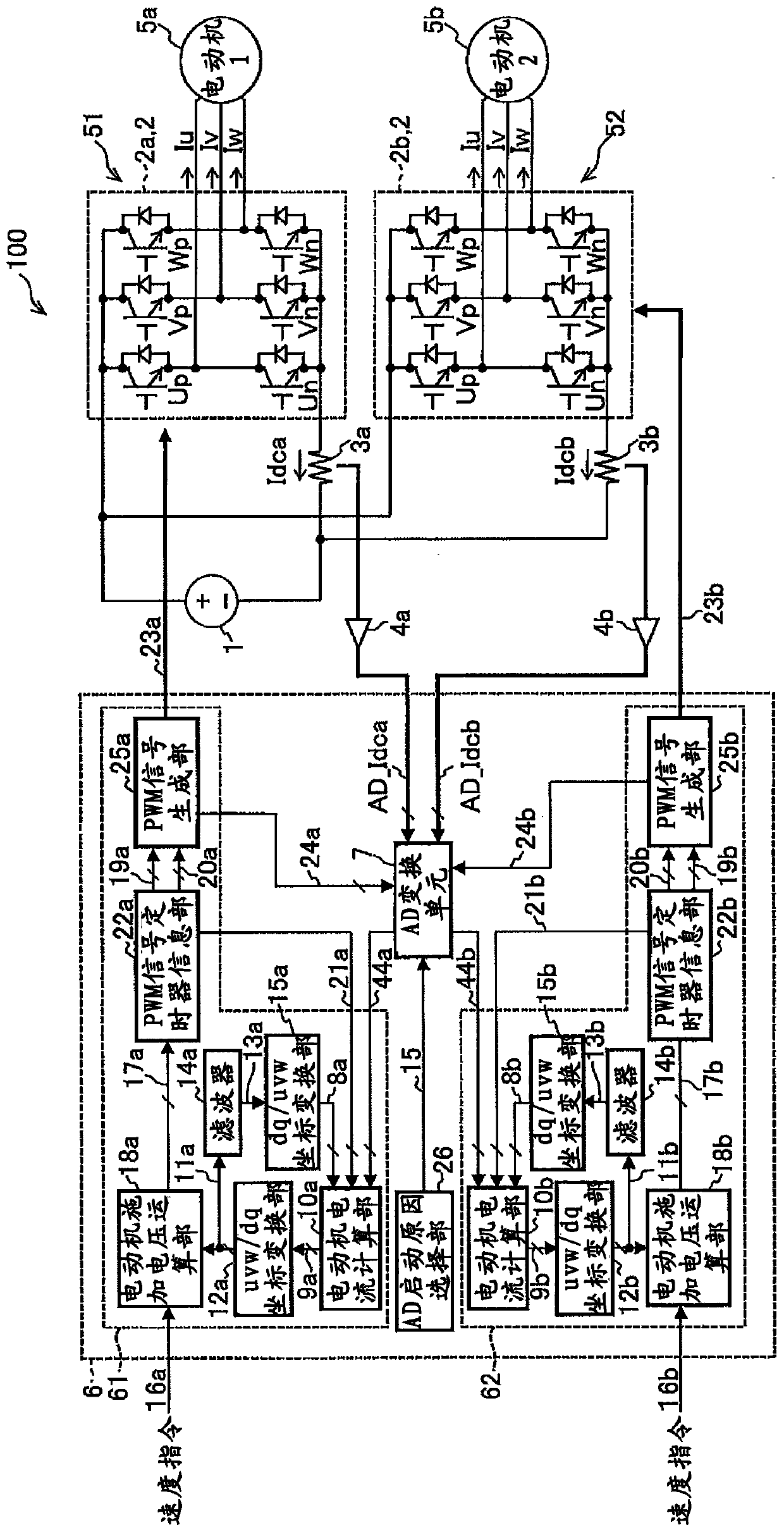

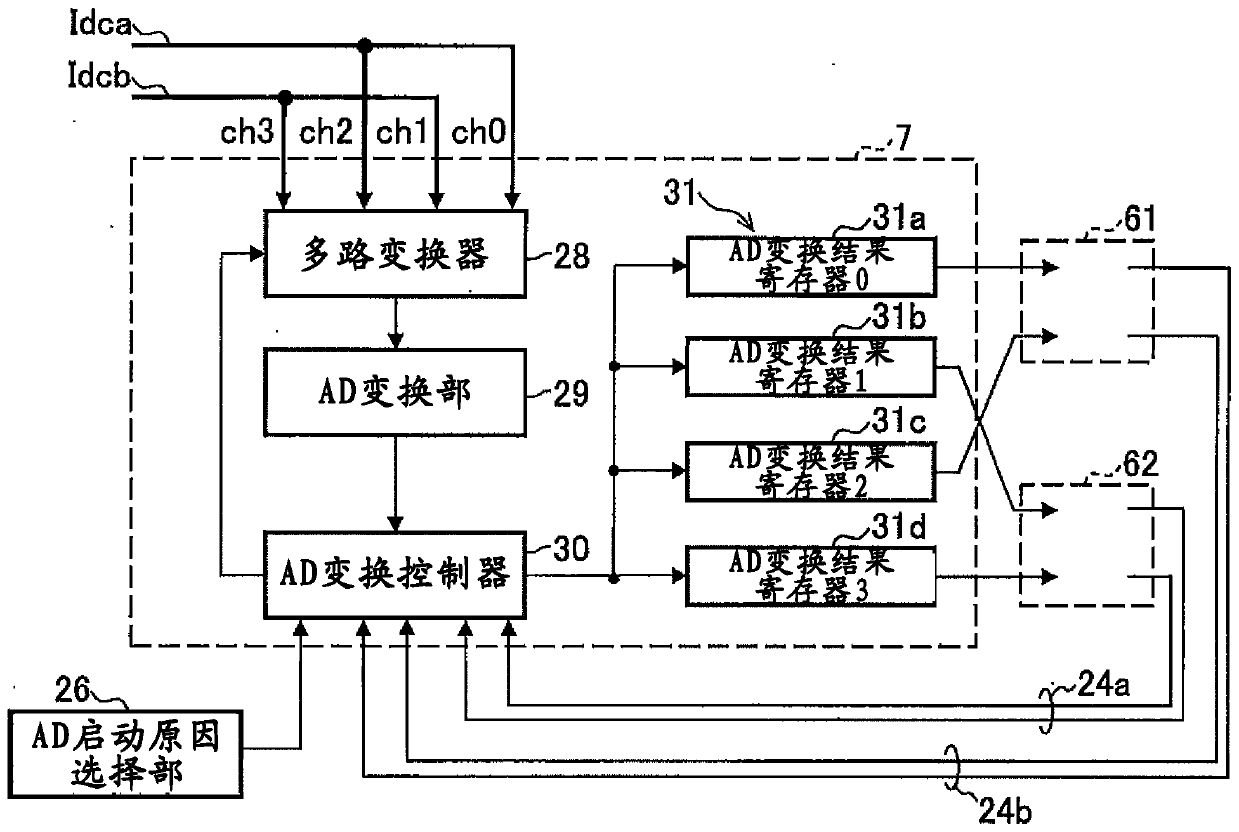

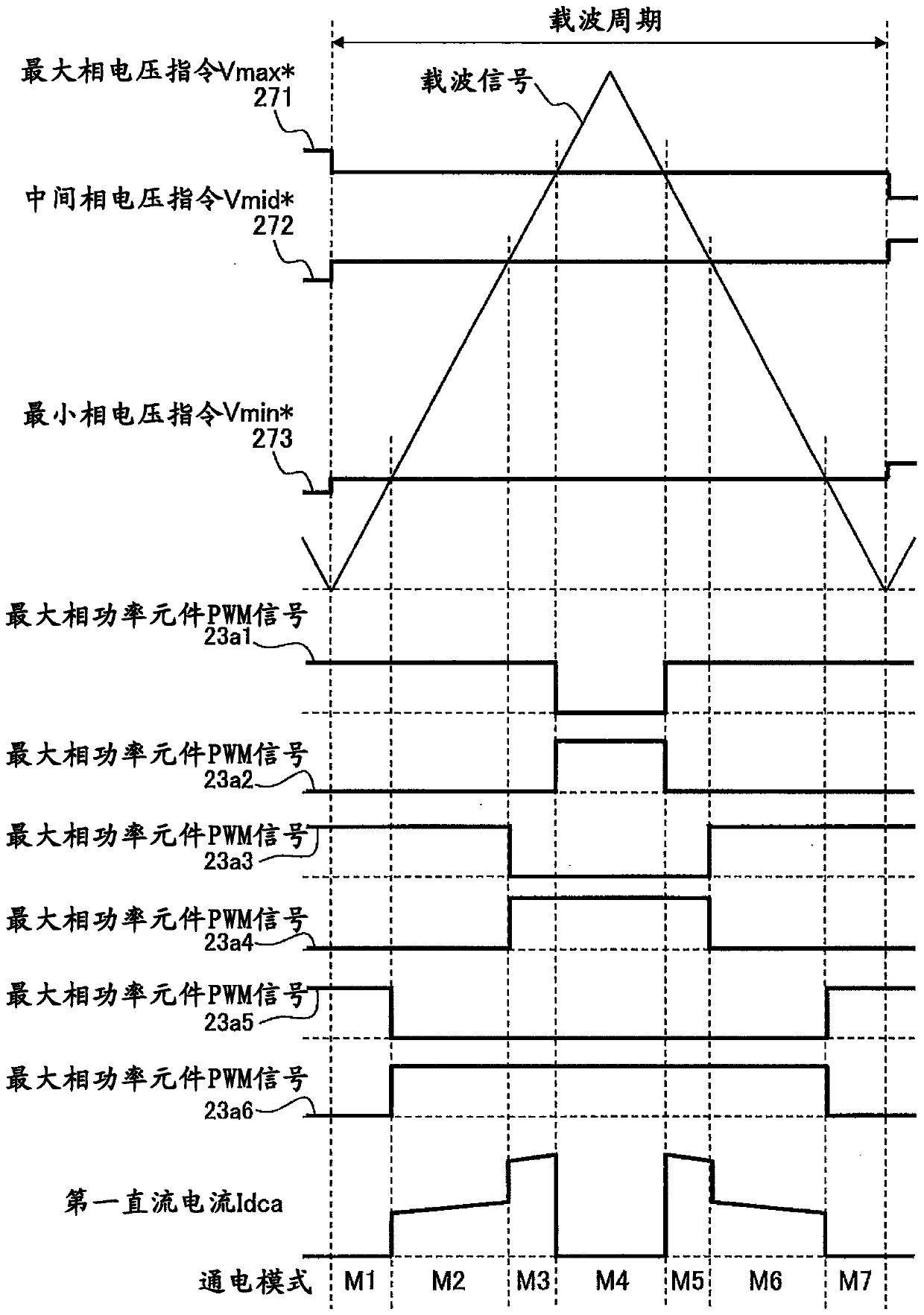

[0067] figure 1 It is a block diagram showing the inverter control device according to the first embodiment of the present invention. In each figure, the same reference numerals are assigned to common constituent elements, and overlapping descriptions are omitted.

[0068] Such as figure 1 As shown, the inverter control device 100 includes: a DC power supply 1 that supplies DC power, a first inverter unit 51, a second inverter unit 52, and a brushless DC motor (first motor) 5a that can be individually controlled. and the controller 6 (inverter control unit) of the brushless DC motor (second motor) 5b.

[0069]

[0070]The first inverter unit 51 (first inverter circuit) includes: a first inverter circuit 2a for converting DC power from the DC power supply 1 into AC power; The shunt resistor 3a, the voltage amplifying circuit 4a for amplifying the voltage across the shunt resistor 3a, and the brushless DC motor 5a connected to the first inverter circuit 2a.

[0071] The se...

no. 2 approach

[0135] The second embodiment is an example in which the calculation timing of the inverter control is further subtracted.

[0136] Figure 6 The first and second carrier signals, the AD conversion start triggers 24a and 24b, and the calculations of the first inverter control unit 61 and the second inverter control unit 62 of the inverter control device according to the second embodiment of the present invention are shown. timing.

[0137] The structure of the inverter control device of the second embodiment and figure 1 The inverter control device 100 is the same. AD activation reason selection part 26 (refer to figure 1 ) is set to perform AD conversion and inverter calculation of the detection current by taking in the AD converter start trigger 24a, 24b once in four cycles of the PWM carrier (for updating the motor applied voltage information based on the current calculation value ). Also, a selection is made to divide the first inverter calculation by the first inverte...

no. 3 approach

[0141] Regarding the calculation timing of the inverter control, the third embodiment is an example in which the calculation is performed every PWM carrier period.

[0142] Figure 7 The first and second carrier signals, AD conversion start triggers 24a and 24b, and calculations of the first inverter control unit 61 and the second inverter control unit 62 of the inverter control device according to the third embodiment of the present invention are shown. timing.

[0143] The structure of the inverter control device of the third embodiment and figure 1 The inverter control device 100 is the same.

[0144] Such as Figure 7 As shown, the first inverter control unit 61 performs AD conversion when the first carrier signal is counting up, and performs inverter calculation when the first carrier signal is counting down. exist Figure 7 In the example of , the first inverter control unit 61 performs AD conversion when the timing T0 to T1 (T0' to T1') of the carrier half cycle of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com