Ceramic plate preventing scalding and making method

A plate and ceramic technology, applied in the field of kitchen plates, can solve the problems of not being able to fully touch the hands without being hot, complicated operation, large handle volume ratio and hot melt, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

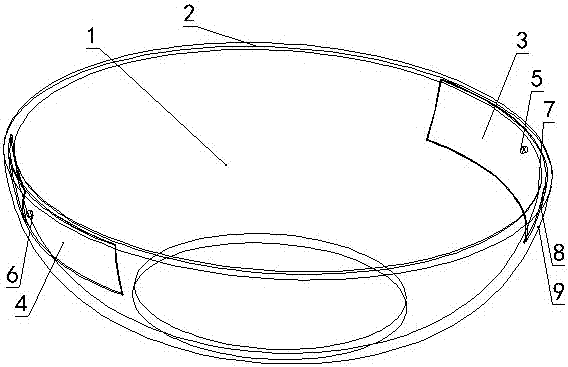

[0014] Embodiment 1 of the present invention: as figure 1 Shown: a non-hot ceramic plate, which includes a plate body 1 and two hollow structures 3, 4, the two same hollow structures 3, 4 are symmetrically arranged relative to the plate body 1, and the hollow structures 3, 4 are separated from the opening of the plate body The distance between the edge 2 is 2cm, the shape of the plate body 1 is a rotating body, the shape of a vegetable plate, and the hollow structure 3 includes a three-layer structure, the inner ceramic layer 7, the middle air layer 8 and the outer ceramic layer, the thickness of the inner and outer ceramics is 1mm, and the entire plate It is composed of two materials with different thermal conductivity. The ceramic material of the hollow structure 3 and 4 has a thermal conductivity not greater than 1w / (m·k). The purpose is to increase thermal resistance and prevent heat from being transferred from the plate to the hand. The plate body 1 The thermal conductiv...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

| Thermal conductivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com