Self-adaptive surface cleaning device for high and big pillar type columns and use method of the self-adaptive surface cleaning device

A surface cleaning device and self-adaptive technology, which is applied in the direction of cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of poor cleaning quality, low efficiency and high safety hazards caused by manual grinding and polishing, and achieve good cleaning effect and structural realization Simple and efficient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

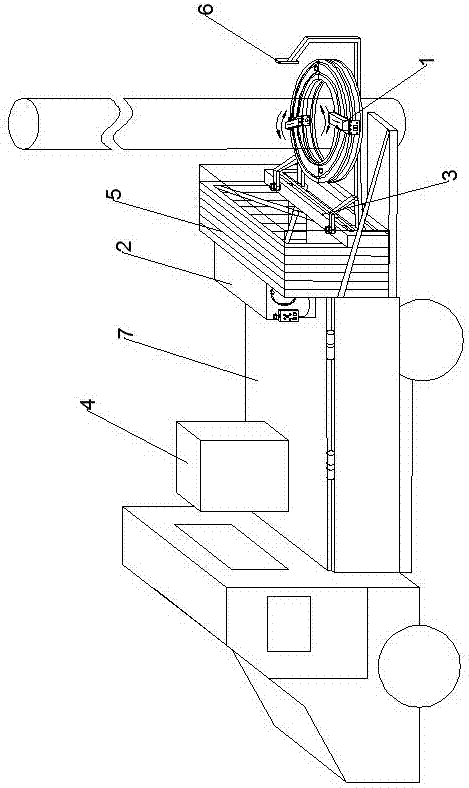

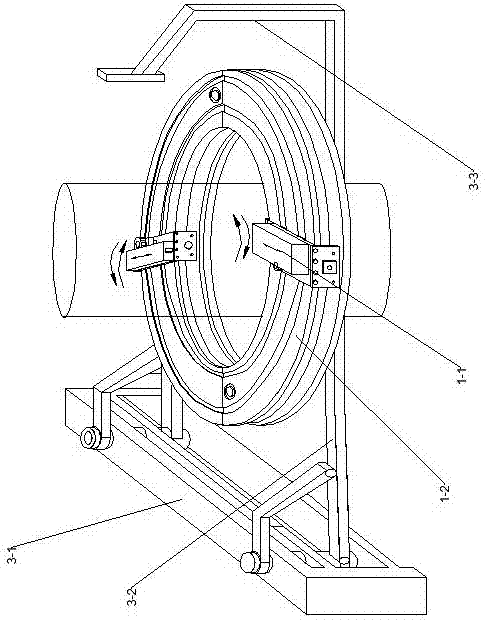

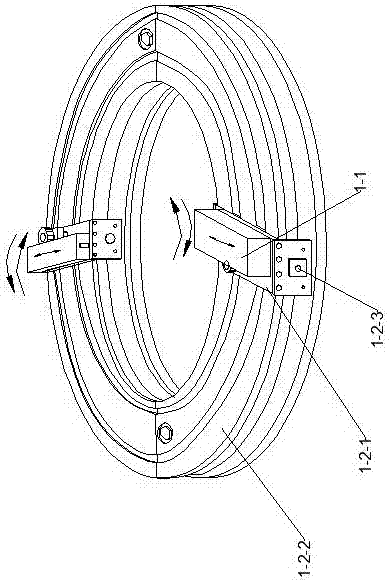

[0020] Such as Figure 1-7 As shown, a kind of self-adaptive surface cleaning device that is used for tall round column, comprises vehicle 7 and controller 2, and vehicle 7 is installed with at least one set of rotating cleaning assembly 1, supporting assembly 3, power supply module 4, lifting platform 5 and The distance measuring module 6, the support assembly is fixedly installed on the lifting platform 5, the rotating cleaning assembly 1 is installed on the support rod 3-2 of the support assembly; the distance measurement module 6 is installed on the distance measurement installation rod 3-3 of the support assembly 3; The rotating cleaning assembly 1 includes a cleaning unit 1-1 and a rotating unit 1-2, the cleaning unit 1-1 is slidably arranged on the rotating bottom plate 1-2-1 of the rotating unit 1-2, and the rotating track of the rotating unit 1-2 The plate 1-2-2 includes two symmetrically arranged semi-circular track plates, and the semi-circular track plate is fixed ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap