Welding method for improving aluminum and steel weldment welding effect

A welding method and technology of welded parts, applied in the direction of welding/welding/cutting articles, welding equipment, laser welding equipment, etc., can solve the problems of poor service characteristics of assemblies, uneven weld composition, and low bonding strength, etc., and achieve good results The effect of promoting value, improving quality and prolonging service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

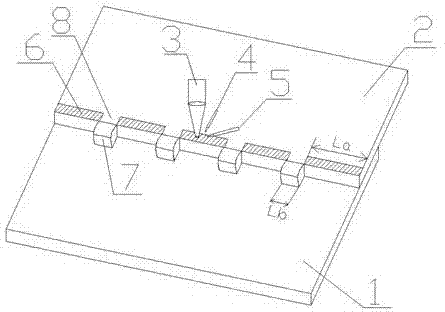

[0027] A welding method for improving the welding effect of aluminum and steel welded parts, comprising the following steps:

[0028] (1) Surface treatment:

[0029] The surfaces of the aluminum weldment 2 and the steel weldment 1 to be welded are respectively subjected to oxidation film and oil removal treatment in sequence;

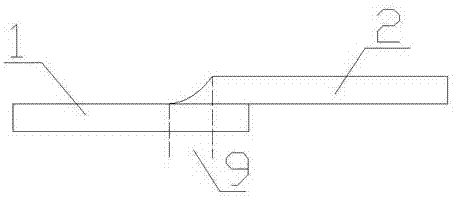

[0030] (2) Lap joint treatment:

[0031] Place the aluminum welded part 2 processed in step (1) directly above the steel welded part 1 for lap joint, and the length of the lap joint is 5-8 mm;

[0032] (3) Modified powder addition treatment:

[0033] The modified powder and the solvent are mixed evenly according to the mass ratio of 1:1.8 to obtain a paste additive, and then the paste additive is coated on the upper surface and side surface of the aluminum weldment 2, correspondingly forming the upper surface additive strip 6 and The side surface additive stack 7, the upper surface additive strip 6 and the side surface additive stack 7 are continuous...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com