Direct burial type asphalt waterproof roll and preparation method thereof

A waterproof membrane and asphalt-based technology, which is applied in the field of direct-buried asphalt waterproof membrane and its preparation, can solve the problems of poor bonding and easy separation of concrete and asphalt membranes, and achieve safety and environmental protection. , saving cost, saving production and use cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

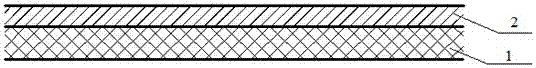

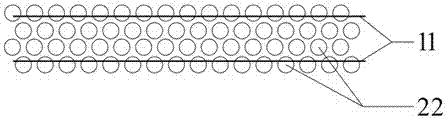

Image

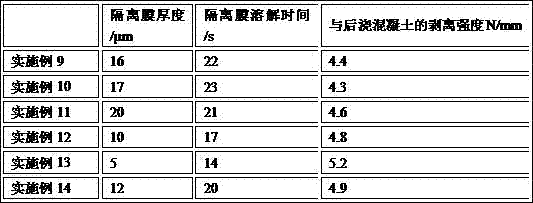

Examples

Embodiment 1

[0061] Prepare the following raw materials for the preparation of the asphalt waterproof membrane material with the isolation membrane material in the following weight percentages:

[0062] Polyvinyl alcohol 17-88 85%;

[0063] Quartz sand (300 mesh) 5%;

[0064] Sodium hexametaphosphate 2%;

[0065] Sodium Lauryl Sulfate 1%;

[0066] Glycerol 3%;

[0067] The rest is water.

[0068] Mix the above materials in a reaction kettle, heat to 80°C, add water and stir at the same time to make a hydrosol solution with a solid content of 12%. isolation film.

Embodiment 2

[0070] Others are the same as in Example 1, the difference is that the raw materials and percentages of the isolation membrane material for the asphalt waterproof coiled material are as follows:

[0071] Polyvinyl alcohol 17-88 90%;

[0072] Quartz sand (600 mesh) 2.5%;

[0073] Sodium tripolyphosphate 1.5%;

[0074] Sodium Lauryl Sulfate 1.5%;

[0075] Glycerol 1%;

[0076] The rest is water.

Embodiment 3

[0078] Others are the same as in Example 1, the difference is that the raw materials and percentages of the isolation membrane material for the asphalt waterproof coiled material are as follows:

[0079] Polyvinyl alcohol 17-88 80%;

[0080] Talc powder (1000 mesh) 6%;

[0081] Sodium pyrophosphate 3%;

[0082] Sodium dodecylbenzenesulfonate 3%;

[0083] Polyethylene glycol 2%;

[0084] The rest is water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com