Underground oil tank lining structure of gas station and construction method

A technology for oil storage tanks and gas stations, which is applied in the directions of containers, packaging, transportation and packaging, etc. It can solve the problems of poor working conditions for construction workers, affecting the construction period, and large environmental pollution, so as to protect the health of workers, shorten the construction period, and The effect of low overall cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

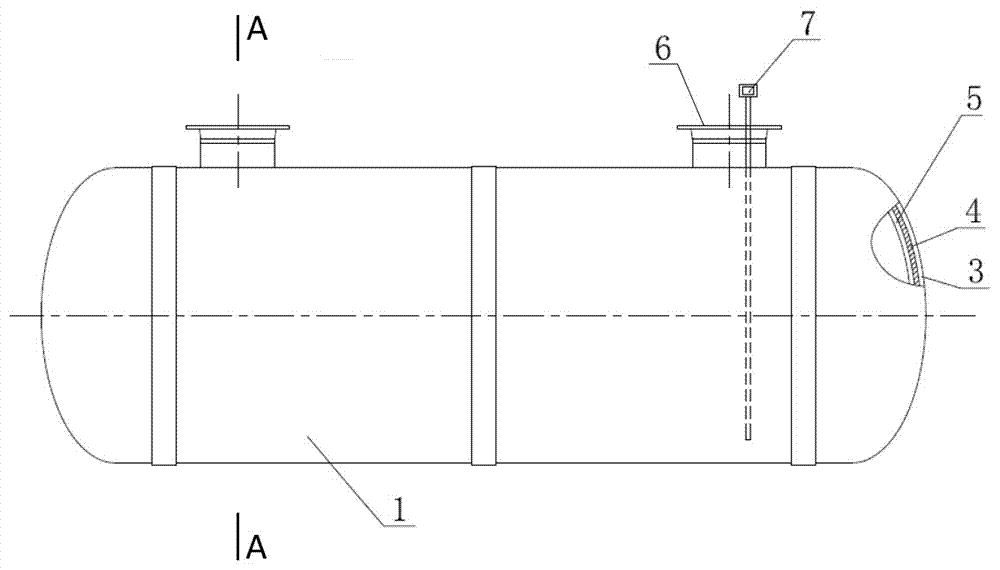

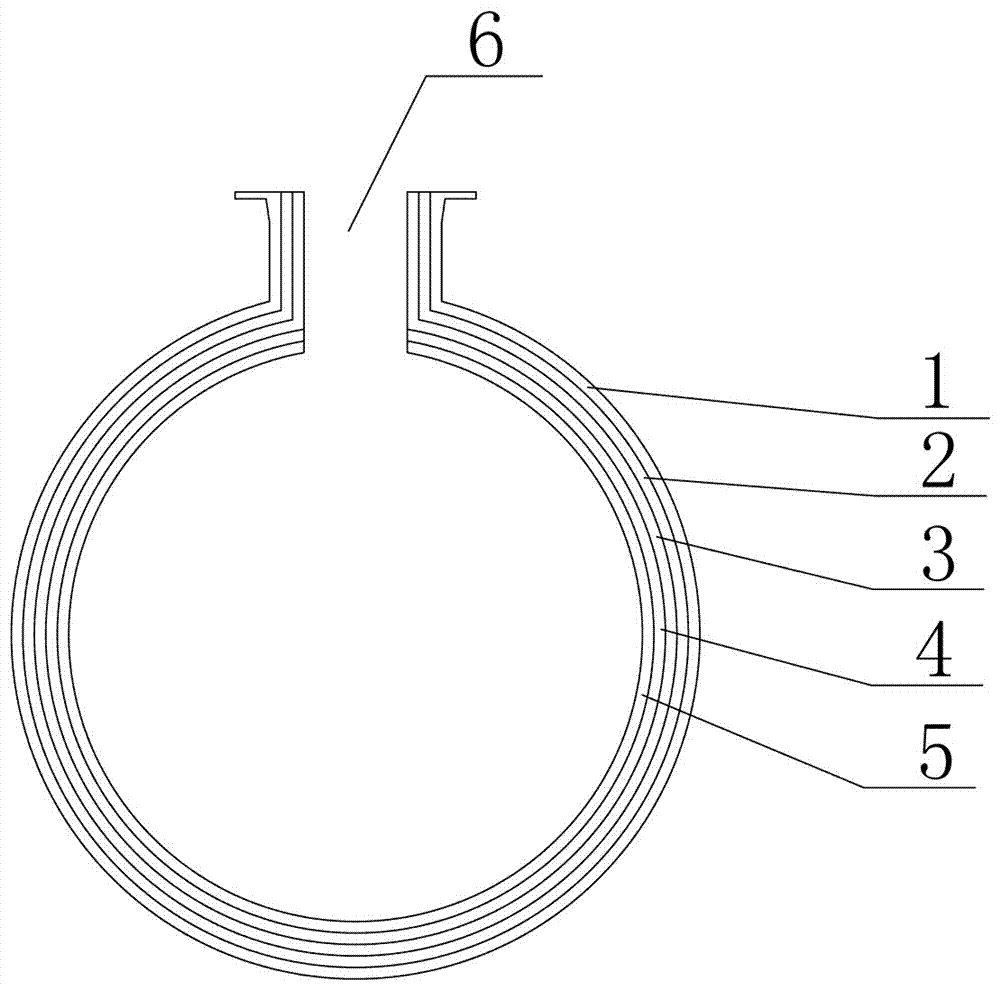

[0029] An underground oil storage tank lining structure of a gas station, including an underground oil storage tank, and two layers of glass fiber reinforced composite materials placed inside the oil storage tank, characterized in that: the underground oil storage tank The inner cavity, starting from the inner surface of the steel tank body 1 of the oil storage tank, is sequentially placed with the outer glass fiber reinforced composite material 3, the middle gap layer 4, and the inner glass fiber reinforced composite material 5 from the outside to the inside; The outer layer of glass fiber reinforced composite material 3 is closely attached to the inner surface of the underground oil storage tank steel tank body 1, and the other side of the outer layer of glass fiber reinforced composite material 3 is connected to the inner surface of the steel tank body 1 through the middle gap layer 4. The inner glass fiber reinforced composite material 5 is adjacent to each other; the middl...

Embodiment 2

[0042] The construction method of the double-layer lining structure of the underground oil storage tank of the gas station comprises the following steps:

[0043] 1. Design of the double-layer lining structure of the oil storage tank: In the same way as in Example 1, fully consider the factors that affect the strength, such as fiber and product type, resin type, laying sequence direction and number of layers, molding process, and resin content, to determine the outer lining. Thicknesses of layers of glass-reinforced composite material, interstitial layer, and inner layer of glass-fiber-reinforced plastic.

[0044] at 30m 3 Take the oil tank as an example, its diameter is 2.4m, and its length is 7.2m. It is made of commercially available OCV company chopped strand mat M 450 and 600g square grid cloth as reinforcement materials, and MERICAN 9505-50 light-curing resin with a resin content of 55%. The tensile strength of the composite material is 190MPa, the tensile modulus is 12...

Embodiment 3

[0053] 1. The double-layer lining structure design of the oil storage tank: 50m 3 Take the oil tank as an example, its diameter is 2.8m, its length is 8.0m, using OCV company chopped strand mat M 450 and 600g square grid cloth as reinforcement materials, MERICAN 9505-50 photocurable resin, resin content 55%, made of composite The tensile strength of the material is 190MPa, the tensile modulus is 1275MPa, the elongation at break is 1.8%, the bending strength is 303MPa, and the bending modulus is 1235MPa. The thickness of the outer glass-reinforced composite material is designed to be 4mm, using 4 mats and 3 cloth (felt / cloth / felt / cloth / felt / cloth / felt) layer structure, the middle gap layer is 5mm, and the thickness of the inner glass-reinforced composite material is 3mm. Adopt 3 felts 2 cloths (felt / cloth / felt / cloth / felt) layer structure.

[0054] 2. Dry ice derusting and primer coating on the inner surface of the oil tank are the same as in Example 1.

[0055] 3. Constructio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com