Automatic rod delivery mechanism of cracking furnace

A pyrolysis furnace, automatic technology, applied in the direction of conveyors, conveyor objects, transportation and packaging, etc., can solve the problems of low loading and unloading rod efficiency, reduce the waste processing efficiency of the waste pyrolysis furnace, and high labor intensity, so as to improve the waste processing efficiency. , the effect of reducing labor intensity and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

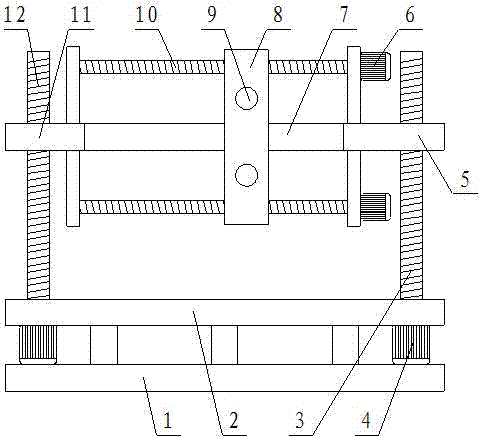

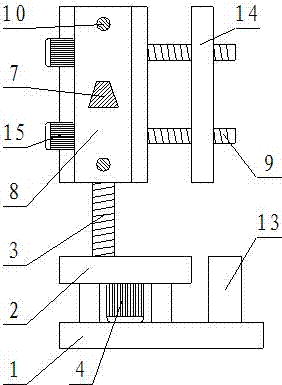

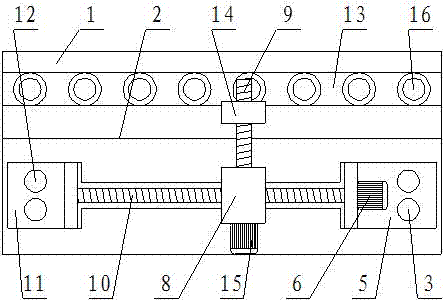

[0017] Such as figure 1 , figure 2 with image 3 Shown, a kind of pyrolysis furnace automatic rod feeding mechanism, it comprises base 1, and the upper surface of described base 1 is provided with motor frame 2, and the positions close to two ends on described motor frame 2 are respectively provided with vertical screw rod A3 and vertical Screw rod B12, described vertical screw rod A3 and the position near the bottom end of vertical screw rod B12 are connected with motor frame 2 in rotation, and the bottom end of described vertical screw rod A3 and vertical screw rod B12 is connected with motor A4, and described vertical screw rod A3 and The position close to the top on the vertical screw rod B12 is respectively threadedly connected with lifting platform A5 and lifting platform B11, and a slideway 7 is fixed between the described lifting platform A5 and the lifting platform B11. Mobile frame 8, described mobile frame 8 is threadedly connected with horizontal screw rod A10, ...

Embodiment 2

[0020] Such as figure 1 , figure 2 with image 3 Shown, a kind of pyrolysis furnace automatic rod feeding mechanism, it comprises base 1, and the upper surface of described base 1 is provided with motor frame 2, and the positions close to two ends on described motor frame 2 are respectively provided with vertical screw rod A3 and vertical Screw rod B12, described vertical screw rod A3 and the position near the bottom end of vertical screw rod B12 are connected with motor frame 2 in rotation, and the bottom end of described vertical screw rod A3 and vertical screw rod B12 is connected with motor A4, and described vertical screw rod A3 and The position close to the top on the vertical screw rod B12 is respectively threadedly connected with lifting platform A5 and lifting platform B11, and a slideway 7 is fixed between the described lifting platform A5 and the lifting platform B11. Mobile frame 8, described mobile frame 8 is threadedly connected with horizontal screw rod A10, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com