Depositing cavity device for preparing optical fiber perform by VAD and cleaning method

An optical fiber preform and deposition cavity technology, which is applied in the directions of cleaning methods, cleaning methods and utensils, and glass manufacturing equipment using gas flow, can solve problems such as harm to the health of workers, pollution, and difficulty in cleaning work, so as to ensure long-term Stability, health protection, avoid the effect of drifting around

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings.

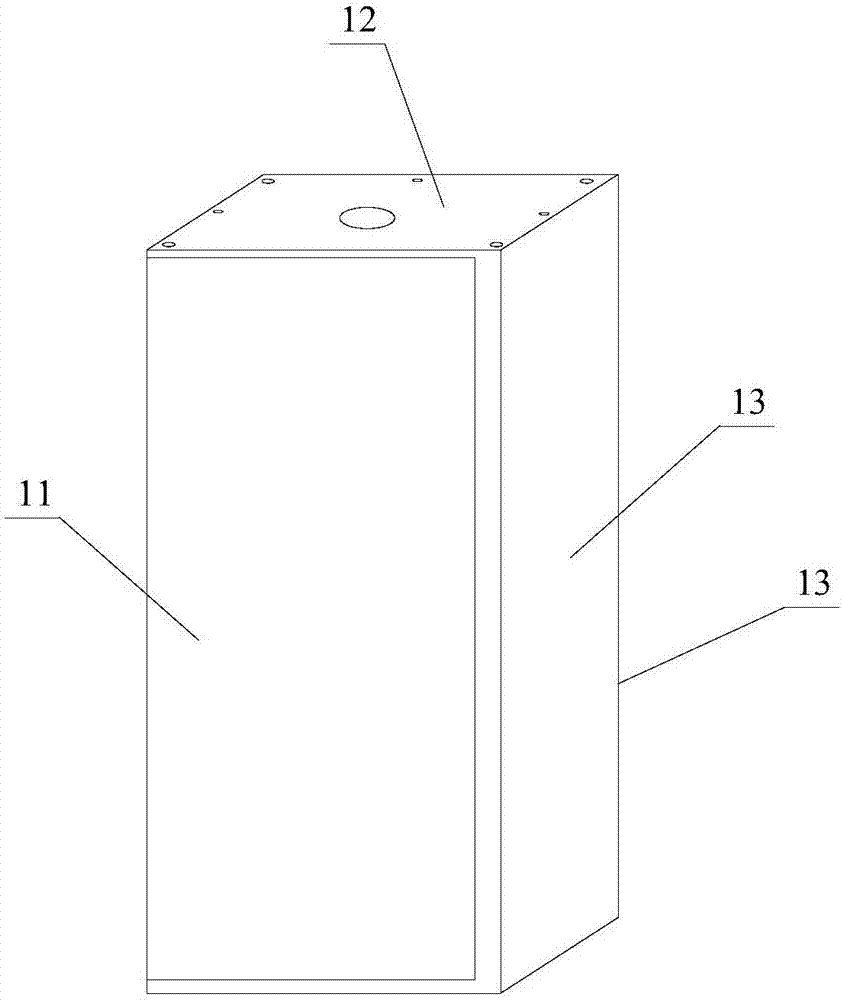

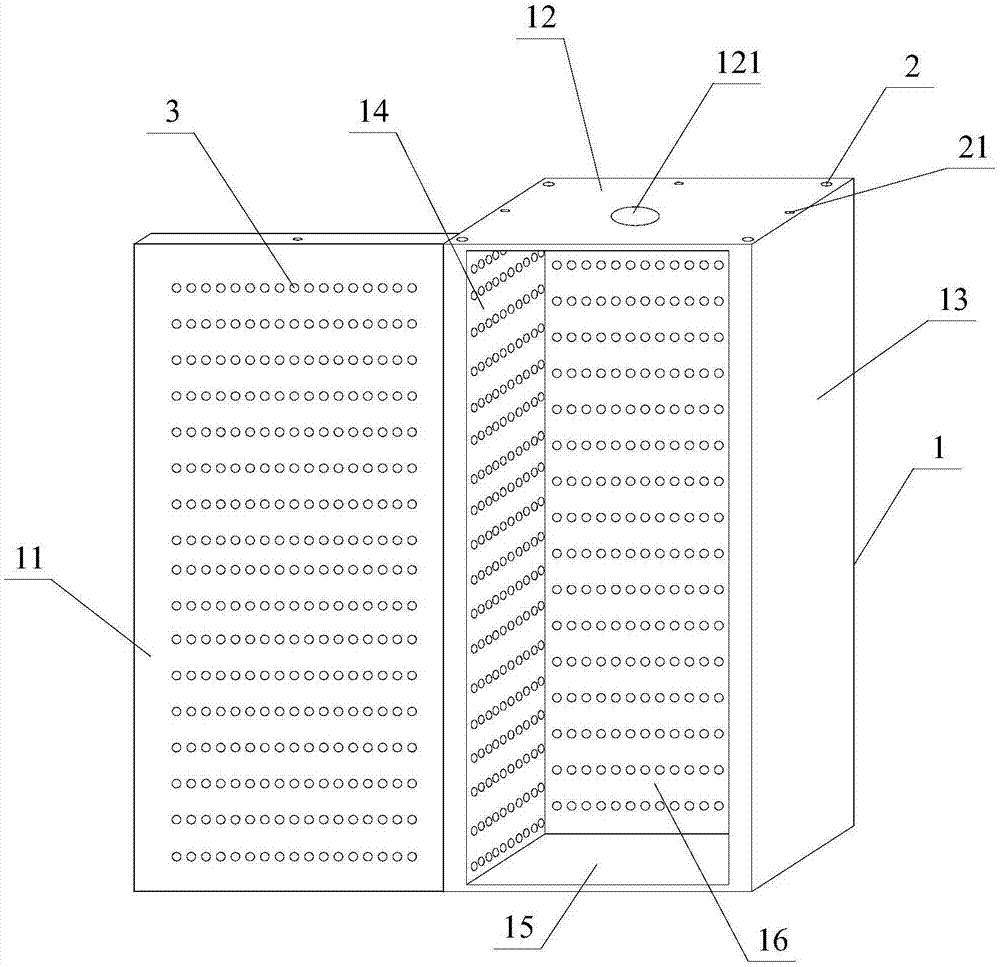

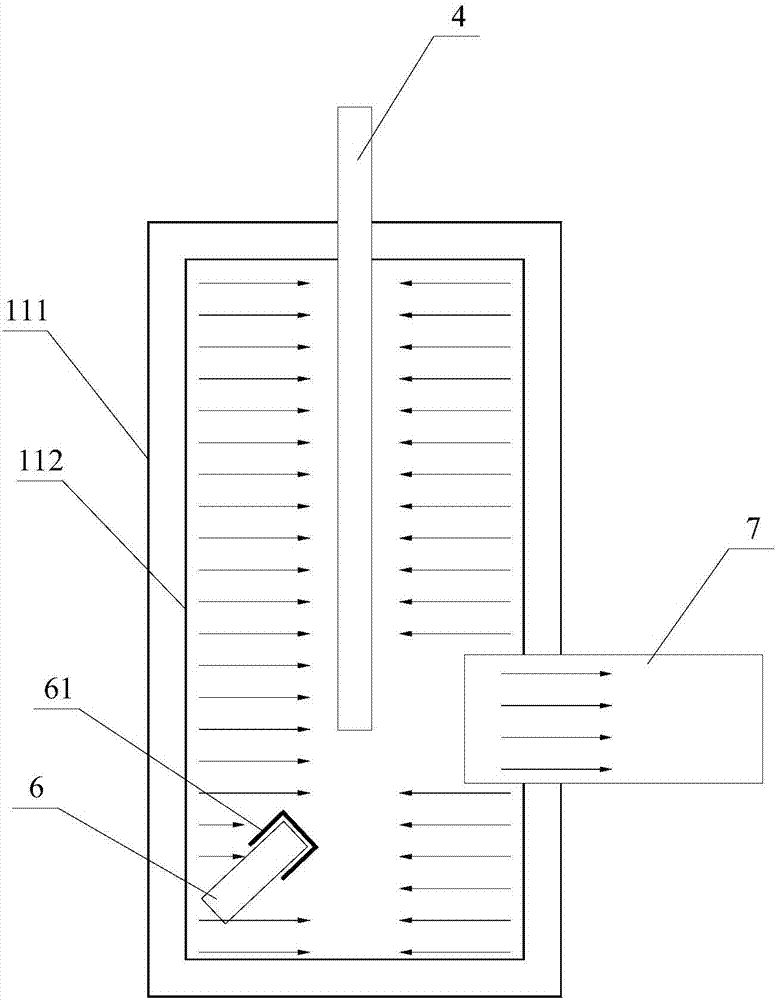

[0035] Such as Figure 1 ~ Figure 3 As shown, the present invention provides a kind of deposition cavity device that is used for VAD to prepare optical fiber preform, comprises deposition cavity 1 and the bubble level instrument 2 that is arranged on deposition cavity 1 upper end, and deposition cavity 1 consists of top plate 12, bottom plate 15 , door panel 11, rear panel 16, left panel 14 and right panel 13 to form a closed cavity structure, wherein the door panel 11 can realize the function of opening and closing. The door panel 11, the rear panel 16, the left panel 14 and the right panel 13 all adopt a double-layer structure, including an inner panel 112 and an outer panel 111, and the distance between the inner panel 112 and the outer panel 111 is 30-45mm. This double-layer structure increases the stability of the deposition chamber 1 , ensures that the compone...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com