Subgrade construction method for sidewalk water-permeable brick and water-permeable brick

A construction method and technology of permeable bricks, which can be applied to roads, roads, road surfaces, etc., can solve the problems of inability to achieve the combination of strength and high water permeability, poor freeze-thaw resistance, and inconvenient maintenance, etc. Good freeze-thaw performance, solve the effect of compatible strength and water permeability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

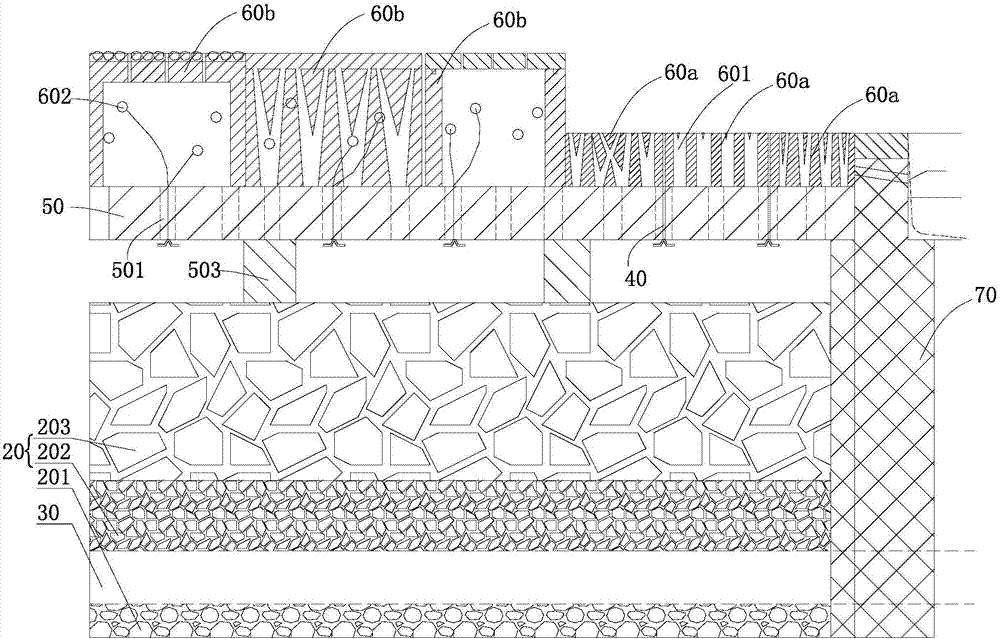

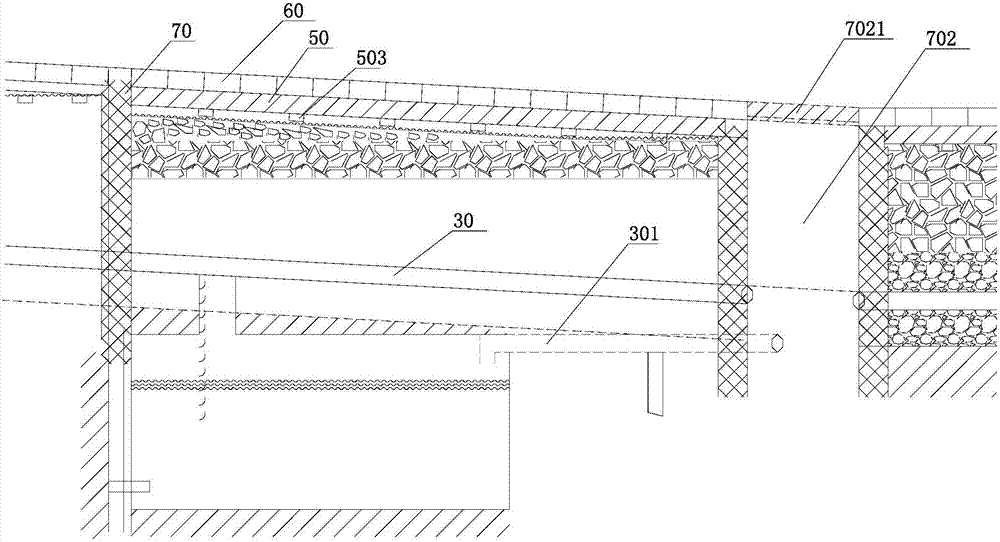

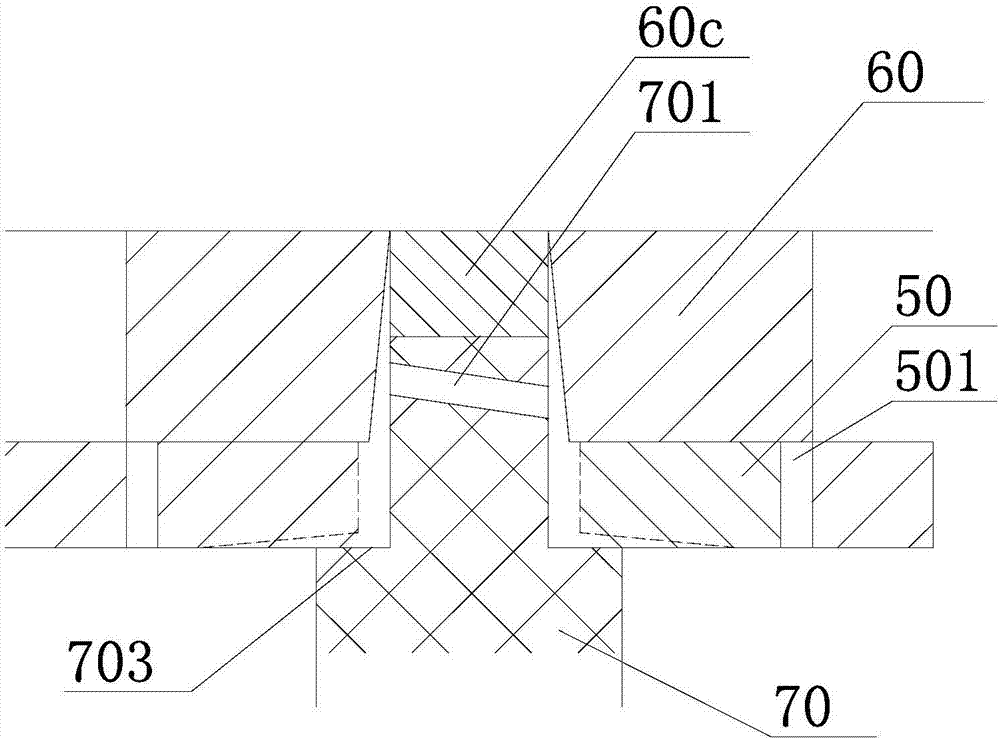

[0055] Embodiment 1; as Figure 1 to Figure 8 ,as well as Figure 17 to Figure 21As shown, on the sidewalk 10 to be constructed, a foundation pit 101 with a predetermined depth and width is dug according to the drawings, and the soil foundation at the bottom of the foundation pit 101 is compacted, and the structures of the curb 102, the retaining wall 70 and the seepage well 702 are as required After the masonry is completed, the distance between the water retaining walls 70 is determined according to the slope of the sidewalk 10. When the slope is larger, that is, the angle of inclination is larger, the distance between the water retaining walls 70 is smaller. The design can avoid that the actual water capacity of the water-holding foundation pit 101 formed between the water-retaining walls 70 will be reduced if the distance between the water-retaining walls 70 is too far. Step 703; then fix the obliquely arranged plastic pipe 701 by cement mortar on the upper part of the wa...

Embodiment 2

[0063] Embodiment 2; as Figure 1 to Figure 7 ,as well as Figure 9 to Figure 21 As shown, compared with Embodiment 1, the difference of this embodiment lies in the difference in the structure of the permeable brick 60 and the same construction steps, which will not be repeated in this embodiment.

[0064] After the permeable horizontal plate 50 is laid, a hard hollow porous brick 60b is laid on the permeable horizontal plate 50. The hollow porous brick 60b here is provided with a rectangular cavity, and the cavity runs through the hollow porous brick 60b. And a cross support frame 604 is provided in the rectangular cavity. In this embodiment, it is preferably a cross support frame 604 connecting the diagonals of the rectangular cavity. The cross support frame 604 divides the cavity porous brick 60b into four parts. , that is, the accumulated water directly penetrates downward from the non-supporting frame 604 part of the rectangular cavity to the permeable horizontal plate 5...

Embodiment 3

[0069] Embodiment 3; as Figure 1-Figure 7 ,as well as Figure 9 to Figure 21 As shown, the difference between this embodiment and Embodiment 2 is that the cavity permeable brick 60 and the permeable surface brick 60c are integrated, so that the design does not require additional bonding construction of the permeable surface brick 60c, and the connecting rod 405 uses a tool from the third through hole Pull it out at 606 and tighten it. The other features of the two are the same, so I won’t go into details here. Of course, the permeable brick 60 also has other similar structural deformations. Change the plane into an uneven surface, and then play the role of wear resistance and anti-skid, so that it can be applicable to the sidewalk 10 in parks or gardens; or the solid porous brick 60a also offers the groove 605 on the side of the cavity porous brick 60b With the fourth through hole 603, this design can also increase the water permeability of the permeable brick 60, etc. For t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com