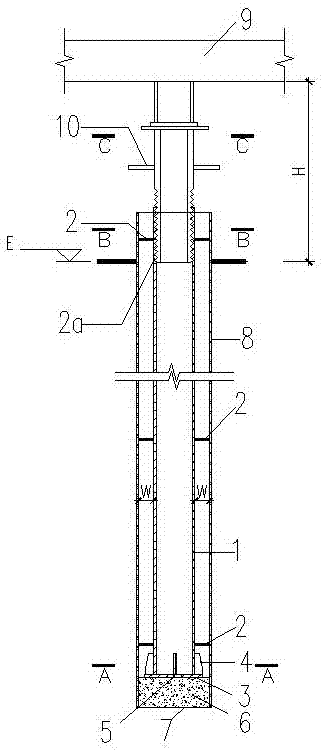

Micro adjustable steel inner pile sleeved pile and construction method thereof

An adjustable, pile casing technology, used in sheet pile walls, infrastructure engineering, construction, etc., can solve problems such as foundation soil deformation, and achieve the effects of eliminating deformation, reliable quality, and high installation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

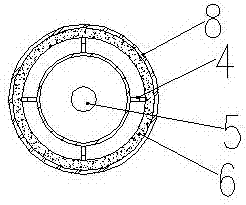

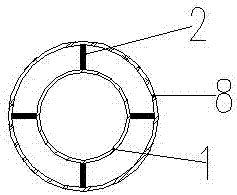

Method used

Image

Examples

Embodiment 1

[0043] 1. Calculate the vertical bearing capacity of a single pile

[0044] According to the empirical relationship between the physical index of the soil and the bearing capacity parameters, the standard value of the ultimate bearing capacity of the single pile is determined;

[0045]

[0046] Qsk: total limit side resistance standard value,

[0047] Qpk: standard value of total limit end resistance,

[0048] qsik: standard value of limit lateral resistance of the i-th layer of soil on the pile side,

[0049] qpk: the standard value of resistance at the ultimate end of the pile,

[0050] Ψsi, ψp: Size effect coefficient of end resistance, see Table 2 for calculation;

[0051] U: Circumference of outer casing,

[0052] Quk: Vertical bearing capacity of a single pile,

[0053] Li: the thickness of the i-th layer of soil,

[0054] Ap: pile tip area.

[0055] Table 2

[0056] soil type

Cohesive soil Silt

sandy soil, gravel soil

Ψsi

(0.8 / D) 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com