Automobile tail gas purifier and coating process of honeycomb carrier

A technology for automobile exhaust and purifiers is applied in chemical instruments and methods, devices for coating liquid on surfaces, coatings, etc. Good purification effect and good filtering effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

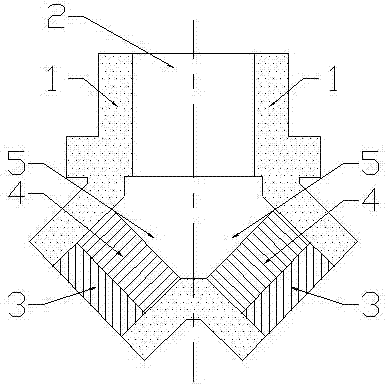

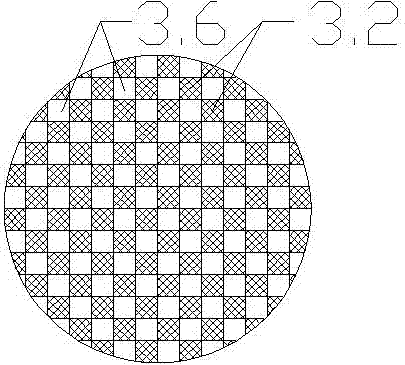

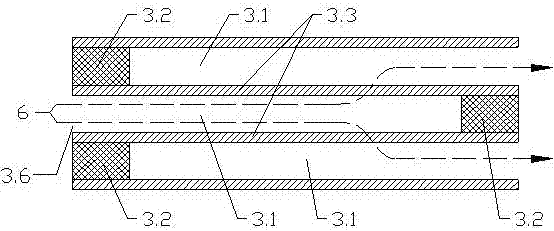

[0034] see Figure 1-4 , the present invention relates to a kind of automobile exhaust purifier, it comprises filter box 1, and described filter box 1 comprises the cylindrical main pipe 2 that is positioned at the upper part and the cylindrical sub-pipe 5 that has two bifurcations in the lower part, and the two The axis line of the branch pipe 5 and the axis line of the main pipe 2 are at an angle of 45° respectively, and the exhaust fine pipe 4 and the ceramic honeycomb carrier 3 are arranged in the said branch pipe 5 along the air flow direction in sequence, and the ceramic honeycomb carrier 3 Corresponding to the inner wall of the branch pipe 5, and the ceramic honeycomb carrier 3 is densely covered with air holes 3.1 along the axial direction, one end of the air holes 3.1 is an opening 3.6, and the other end is provided with a sealing surface 3.2, the sealing surface 3.2 and the opening 3.6 Arranged at intervals, the two adjacent air holes 3.1 are provided with a partitio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com