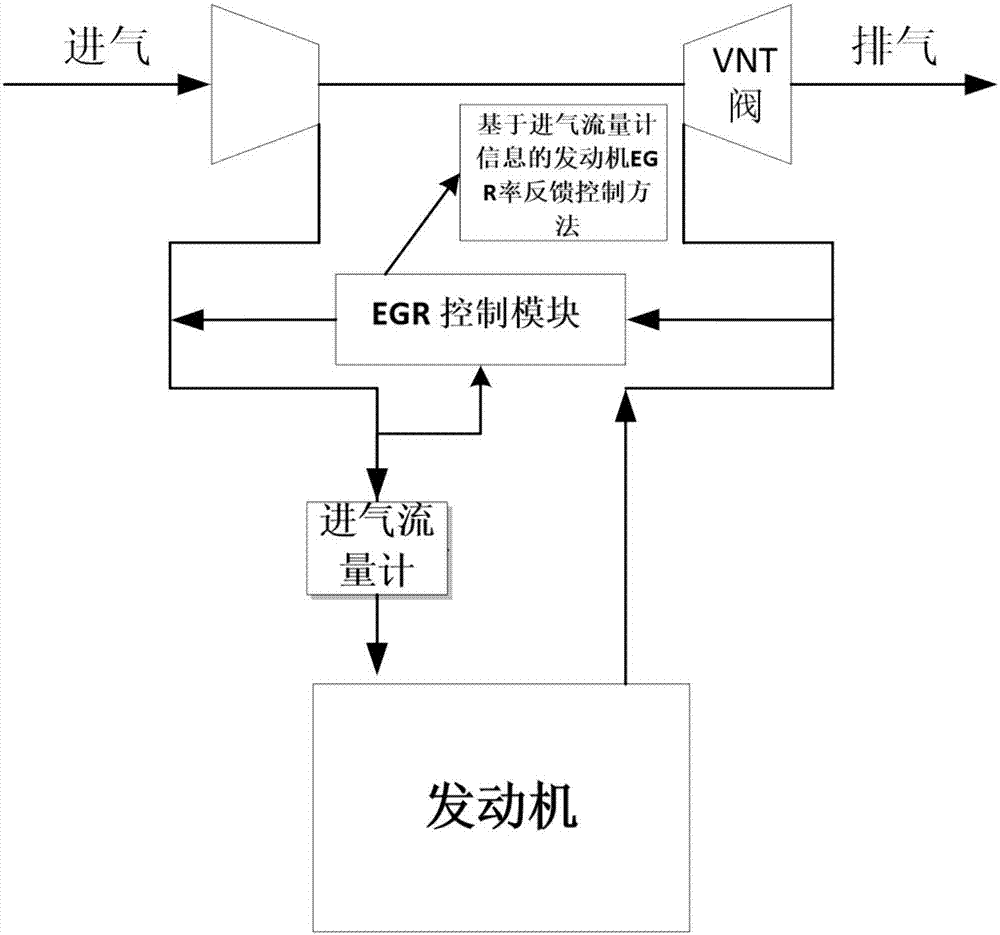

Variable supercharged engine EGR rate feedback control method based on air inlet flowmeter information

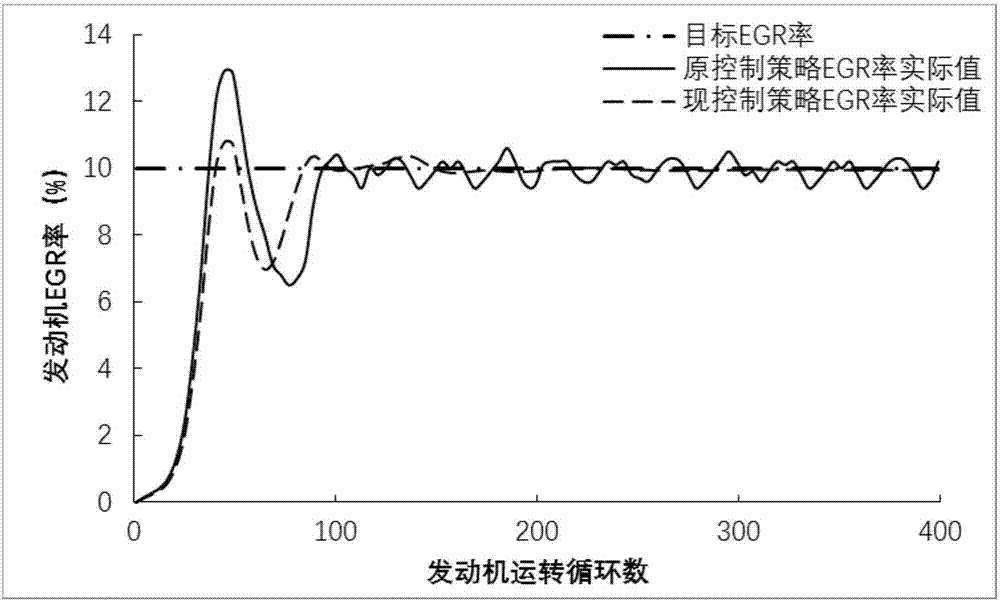

A technology of supercharged engine and intake air flow, applied in engine control, electrical control, machine/engine, etc., can solve problems such as difficulty in accurately controlling EGR rate, to avoid EGR rate fluctuations, ensure consistency, and achieve precise control. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

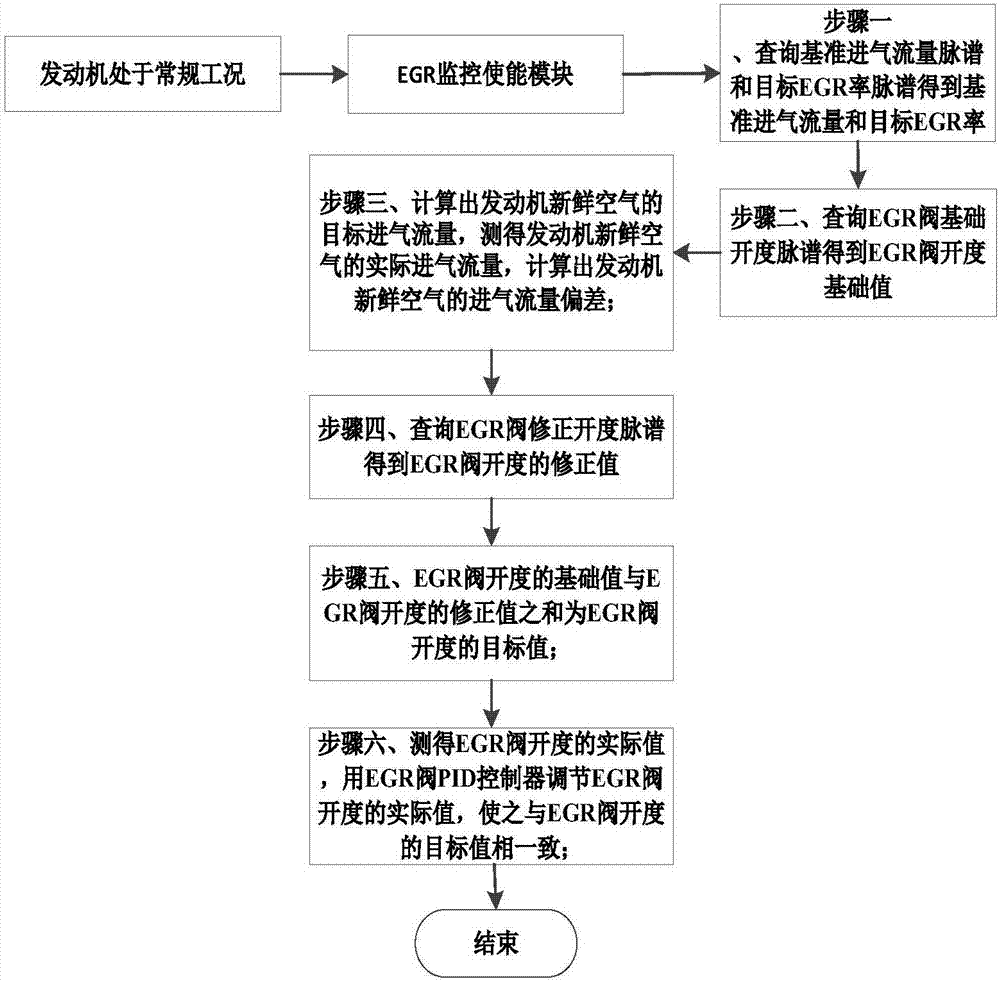

[0018] The present invention will be described in detail below in conjunction with the drawings:

[0019] In order to introduce the content of the present invention in detail, some related concepts are defined:

[0020] Definition 1. Reference intake air flow: Under a certain working condition, when the EGR valve is closed, after calibrating the VNT opening, the total air flow entering the engine cylinder, use q 0 To represent;

[0021] Definition 2: The target intake flow of fresh air: refers to the fresh intake flow required to reach the target EGR rate under the current operating conditions, and q is used in this article Fair1 To represent;

[0022] Definition 3. The actual intake flow of fresh air: refers to the actual fresh intake flow calculated by the intake air flow sensor under the current operating conditions of the engine. In this paper, q Fair2 To represent;

[0023] Definition 4: Intake air flow deviation: refers to the difference between the actual intake air flow of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com