Portable purging and trapping sampler

A purge-and-trap and sampler technology, applied in instruments, scientific instruments, measuring devices, etc., can solve problems such as low peak separation between components, diffusion of sample components, and poor quantitative results, achieving low cost, Solve the serious diffusion of components and reduce the effect of manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

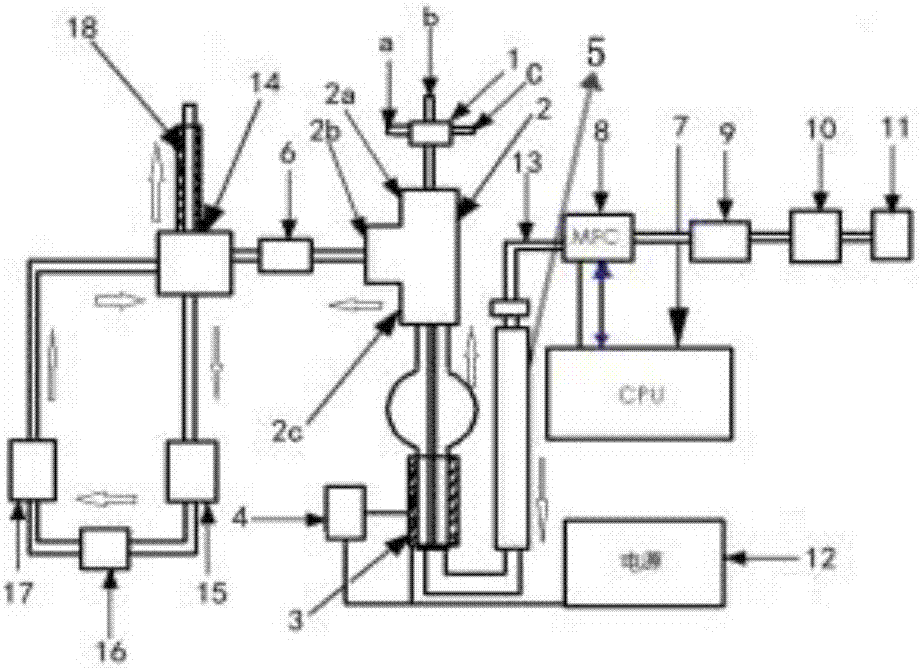

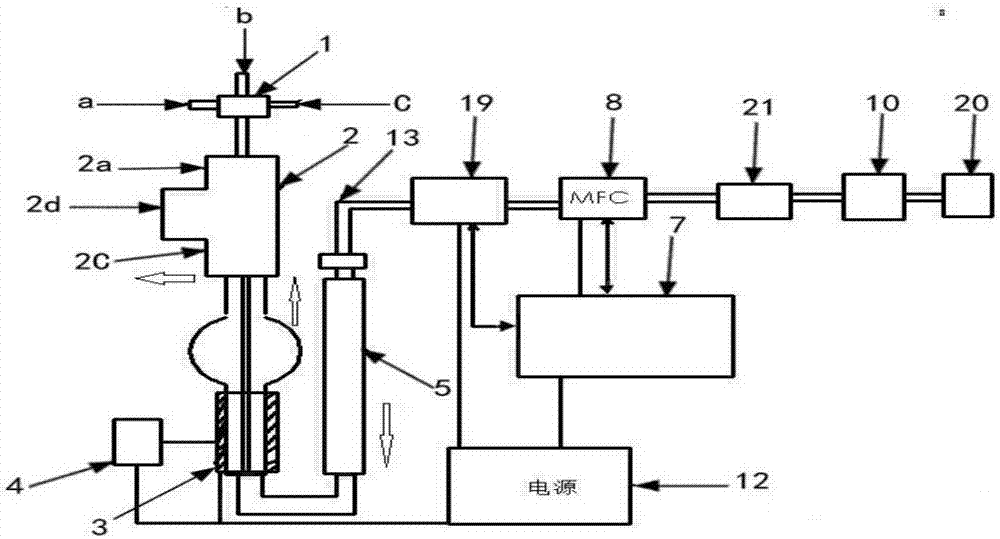

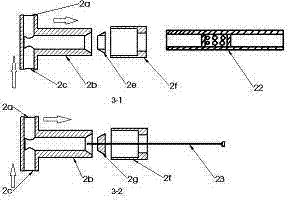

[0032] Please refer to figure 2 , image 3 , Figure 4As shown, (13) is the pipeline connected to the external source purge gas. The material of the pipeline is required to be chemically resistant, chemically inert, and preferably flexible, so that the external source purge gas enters. In this embodiment, a pipeline made of polytetrafluoroethylene is used. The pipeline is installed on the nitrogen or helium source connector I (20). In order to meet the needs of frequent disassembly of the components in the portable equipment, the present invention adopts a quick connector connection, and the material is chemically resistant polymer polymer material, stainless steel or PEEK nut fittings are also available. Through connection I, pipelines of the same specification and material are connected to the online gas filter (10) to remove nanometer-sized mechanical particles and prevent them from entering the downstream gas flow controller and damaging the flowmeter. The online filte...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com