Method for evaluating consistency between direct coal liquefaction residues and petroleum asphalt

A technology of direct coal liquefaction and petroleum asphalt, applied in the field of construction, can solve the problems of no suitable compatibility evaluation method, etc., and achieve the effects of easy operation, low energy consumption, and environmental protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

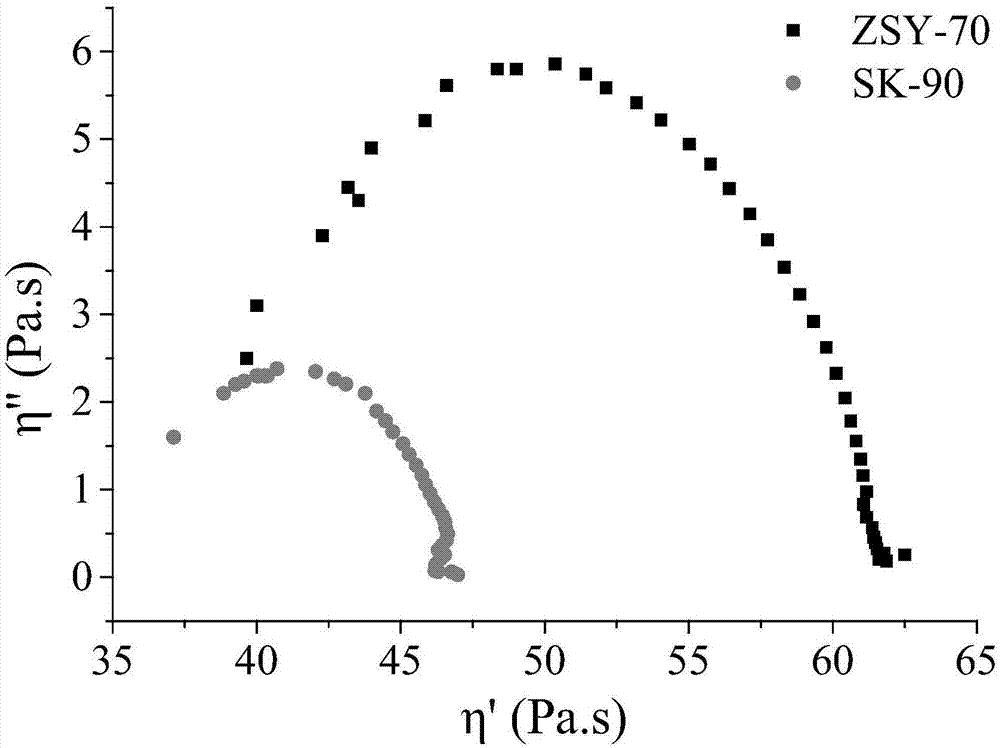

[0048] Petroleum asphalt adopts No. 70 petroleum asphalt (ZSY-70) produced by China National Petroleum Corporation and No. 90 petroleum asphalt (SK-90) produced by South Korea. DCLR comes from Inner Mongolia Shenhua Group.

[0049] 1) Test the performance of DCLR, ZSY-70 and SK-90.

[0050] The properties of DCLR, ZSY-70 and SK-90 are shown in Table 1-3 respectively.

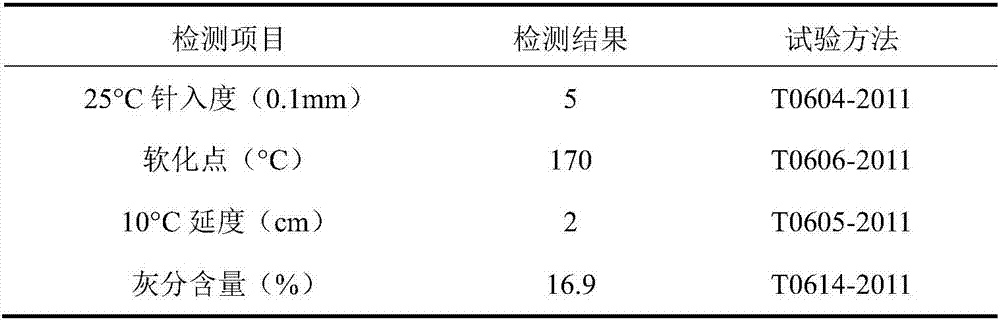

[0051] Table 1 Performance of DCLR

[0052]

[0053] Table 2 Properties of ZSY-70 asphalt

[0054]

[0055]

[0056] Table 3 Properties of SK-90 asphalt

[0057]

[0058] The technical indicators of ZSY-70 and SK-90 petroleum asphalt meet the technical standards for road petroleum asphalt in "Technical Specifications for Construction of Highway Asphalt Pavement" (JTGF40-2004).

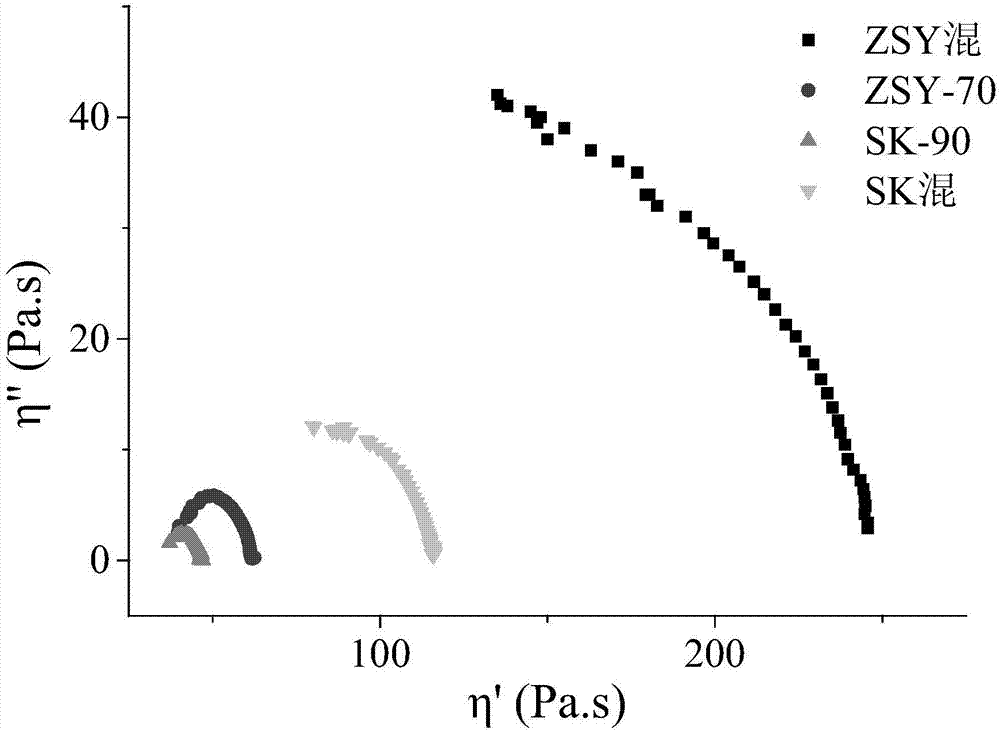

[0059] 2) The blends of DCLR, ZSY-70 and SK-90 were prepared respectively.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com