PCB-based GMI sensor probe and preparation method for the same

A sensor probe, PCB board technology, applied in the direction of instruments, single equipment manufacturing, measuring devices, etc., can solve the problems of difficulty in ensuring the number of coil turns and the stability of the winding diameter, time-consuming and laborious, and achieve flexible and convenient application and mature processing technology. Simple, technically mature effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

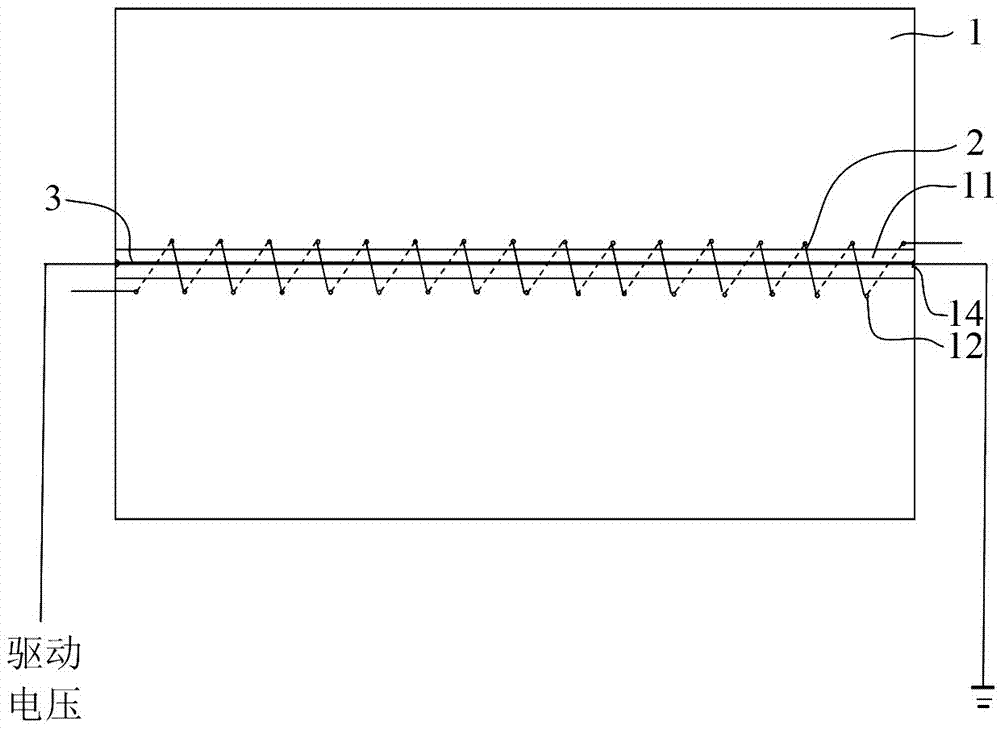

[0016] Such as figure 2 As shown, the GMI sensor probe based on PCB in this embodiment includes a PCB board 1 and a signal pickup coil 2. The PCB board 1 is provided with a groove 11 formed by etching, and the groove 11 is provided with an amorphous wire 3, and the PCB board 1 A row of via holes 12 are respectively provided on both sides of the groove 11 , and the signal pick-up coil 2 is formed by wires passing through the via holes 12 alternately on the front and back sides of the PCB 1 . In this embodiment, the signal pickup coil 2 is not a traditional coil coil, but a zigzag coil.

[0017] In this embodiment, both sides of the PCB board 1 are provided with stamp holes 14 for connecting drive signals, and the two ends of the amorphous wire 3 are respectively connected to the stamp holes 14. The packaging of the amorphous wire 3 is realized through the above structure, ensuring that the amorphous wire 3 The wire 3 connection is stable and reliable.

[0018] In this embodi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com