Method for calculating bearing capacity of steel cover plate node under action of bending moment force

A technology of bearing capacity and cover plate, which is applied in the field of engineering calculation, can solve the problems of damage, failure to consider bolt pre-tightening force, and few experimental studies of steel cover plate joints.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

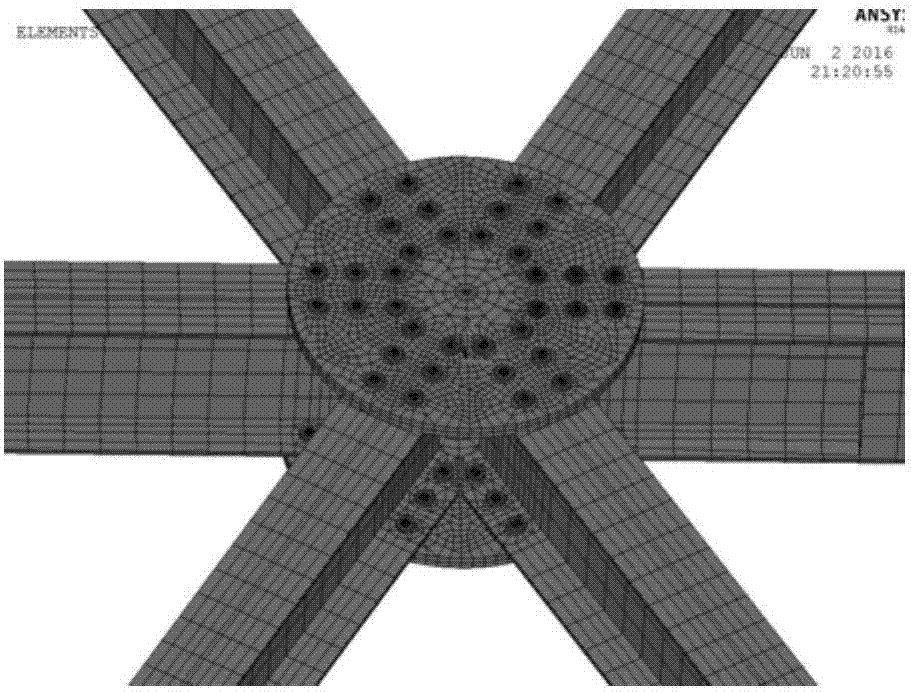

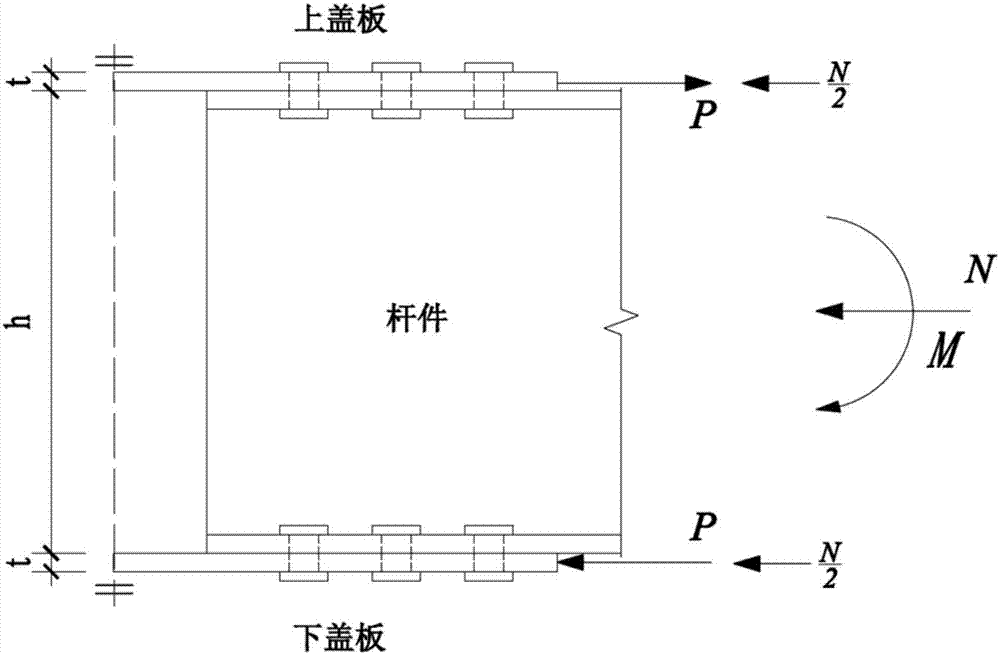

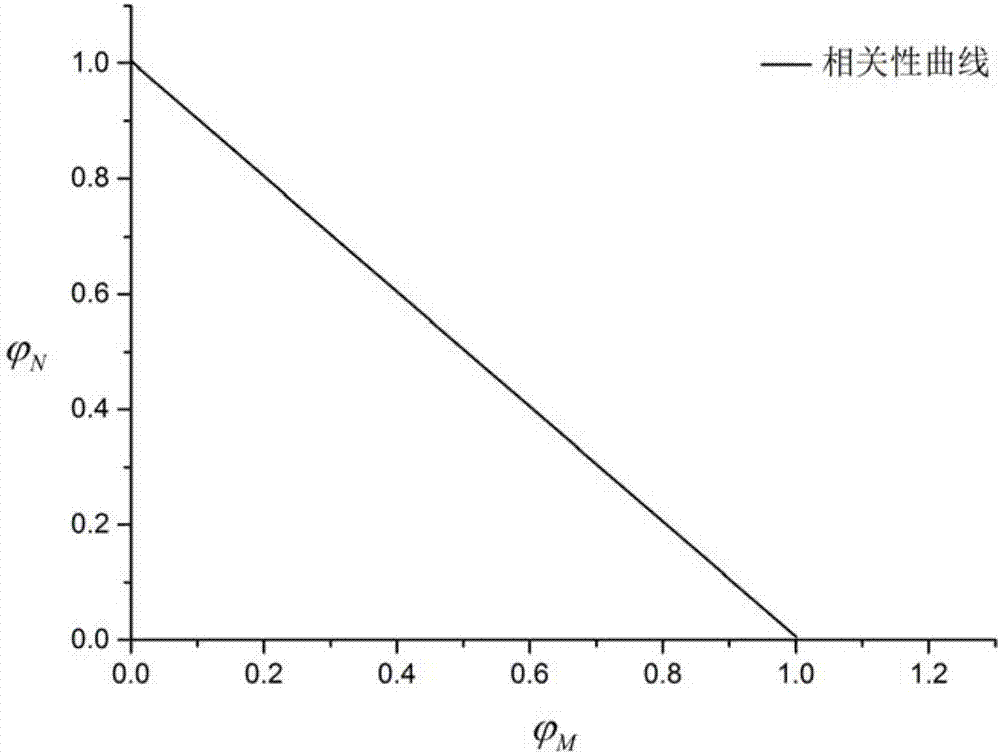

[0179] Given a steel cover plate node, the maximum axial force of the rod is 750kN, the maximum bending moment is 100kN·m, the diameter of the cover is 240mm, the thickness is 16mm, the rod is made of H-shaped steel, the steel is Q235B, and the section size is H250×125×6×8, bolt diameter is 16mm, arranged in 3 rows, such as Image 6 Shown. This cover node is now checked.

[0180] 1. First, calculate the design value N of its compressive bearing capacity under axial pressure u :

[0181] 1 If the bolt shear failure of the steel cover plate node first occurs, its shear capacity is

[0182]

[0183] Among them, the number of bolts on a single rod is n=3×2×2=12, refer to the specification f v b = 250MPa.

[0184] Therefore

[0185] 2 If the buckling failure of the center of the cover plate occurs first in the joint of the steel cover plate, the design value of the buckling failure bearing capacity of the center of the cover plate is:

[0186]

[0187] Among them, according to the arrange...

Embodiment 2

[0211] Given a steel cover plate node, the maximum axial force on the rod is 420kN, the maximum bending moment is 40kN·m, the diameter of the cover is 240mm, the thickness is 12mm, the rod is made of H-shaped steel, the steel is Q235B, and the section size is H250×125×6×8, bolt diameter is 14mm, arranged in 3 rows. This cover node is now checked.

[0212] 1. First, calculate the design value N of its compressive bearing capacity under axial pressure u :

[0213] 1 If the bolt shear failure of the steel cover plate node first occurs, its shear capacity is

[0214]

[0215] Among them, the number of bolts on a single rod is n=3×2×2=12, refer to the specification f v b = 250MPa.

[0216] Calculated

[0217] 2 If the buckling failure of the center of the cover plate occurs first in the joint of the steel cover plate, the design value of the buckling failure bearing capacity of the center of the cover plate is:

[0218]

[0219] Among them, according to the arrangement of bolts, the distan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com