Combined intelligent capacitor

A capacitor and combined technology, applied in the field of capacitors, can solve the problems of narrow spacing between parallel electrical appliances, easy heat damage and other problems, and achieve the effect of solving the problem of installation space, simple overall structure and simple wiring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

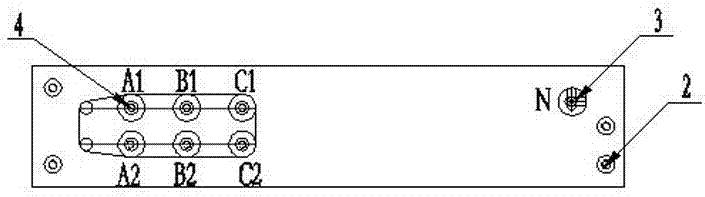

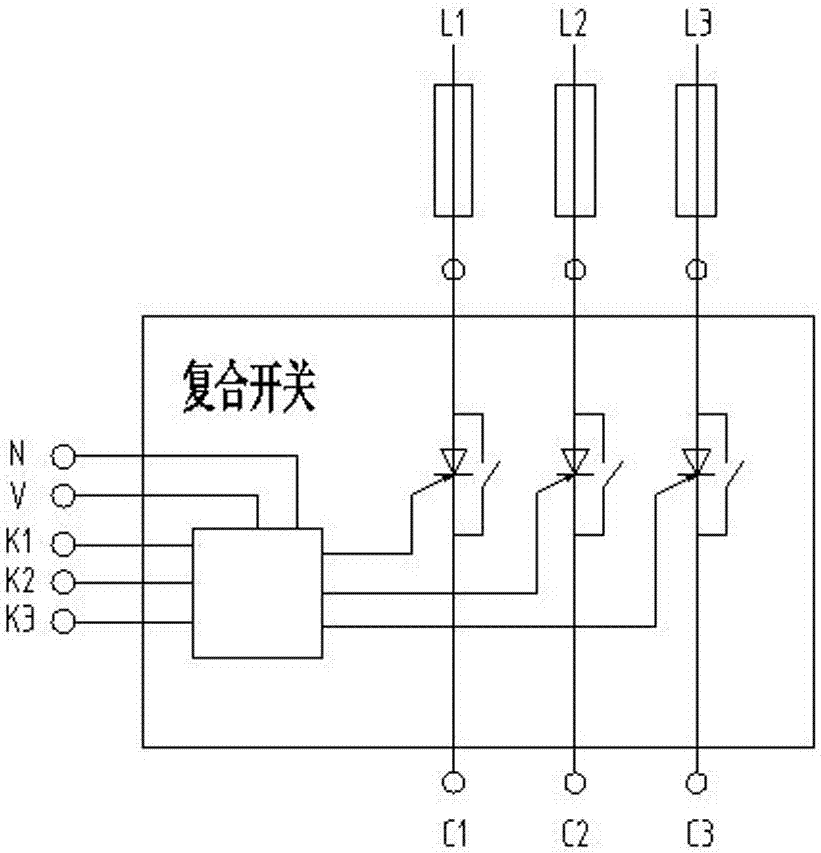

[0010] see Figure 1-3 , the combined smart capacitor is realized through the following technical solutions: it includes a shell 1, a terminal 2, a sub-compensation capacitor zero-phase output end 3, and a three-phase capacitor output end 4 manufactured by a special mold, and the shell 1 The top side is provided with a three-phase capacitor output terminal 4, and the other end is provided with a binding post 2 and a zero-phase output terminal 3 of the sub-compensation capacitor. A composite switch is provided inside the housing 1, and the three-phase input terminals L1, L2, L3 is connected to the power grid, and C1, C2, and C3 at the three-phase output end are connected to capacitors or reactors. The common compensation switch is only connected to the distribution switch K1 to control the three-phase output. The distribution switch K1 controls the output of C1, K2 controls the output of C2, and K3 controls C3. Output, V is connected to the positive pole of the common terminal ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com