Preparation method of liquorice root fermented beverage

A fermented beverage and licorice technology, applied in the direction of yeast-containing food ingredients, bacteria used in food preparation, and the function of food ingredients, can solve the problems of not removing the smell of licorice, unsatisfactory market sales, etc., to improve the taste, taste, Improvement of smell and taste Taste and pleasant flavor effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

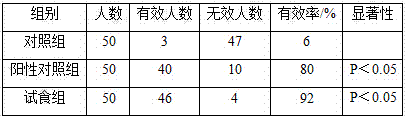

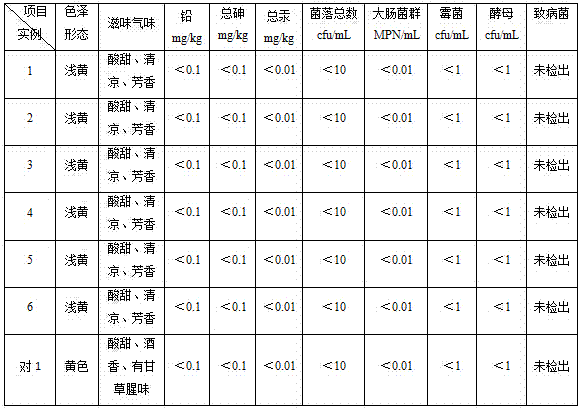

Examples

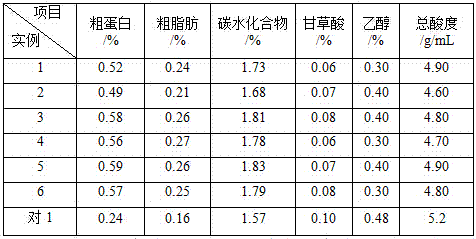

Embodiment 1

[0033] A preparation method of licorice fermented beverage, comprising the following steps:

[0034] (1) Grinding: Grind licorice and mint to 30 mesh respectively, cook and fry tartary buckwheat until fragrant and crush to 40 mesh, mix the three raw materials evenly to obtain a mixture, in which licorice, mint, and buckwheat are The weight ratio is 100:2:5;

[0035] (2) Soaking: Soak the mixture in step (1) and water according to the ratio of material to liquid: 1g: 20mL, shake for 1h, until the content of glycyrrhizic acid is 0.06%, and obtain the soaked product;

[0036] (3) Sterilization: transfer the material soaked in step (2) into a fermenter, add 3% glucose by weight of the soaked material, and sterilize;

[0037] (4) Lactic acid bacteria fermentation: Inoculate 0.6% lactic acid bacteria of the weight of the soaking material in a fermenter, ferment for 8 hours at 40°C until the pH is 3.8, and the total acidity is 4.9g / mL; the lactic acid bacteria are Streptococcus ther...

Embodiment 2

[0043] A preparation method of licorice fermented beverage, comprising the following steps:

[0044] (1) Crushing: Grind licorice and mint to 30 mesh respectively, cook and stir-fry tartary buckwheat until fragrant and crush to 50 mesh, mix the three raw materials evenly to obtain a mixture, in which licorice, mint, and tartary buckwheat The weight ratio is 100:3:5;

[0045] (2) Soaking: Soak the mixture in step (1) and water according to the ratio of material to liquid: 1g: 25mL, shake for 1.5h, until the content of glycyrrhizic acid is 0.07%, and obtain the soaked product;

[0046] (3) Sterilization: transfer the material soaked in step (2) into a fermenter, add 4% glucose by weight of the soaked material, and sterilize;

[0047] (4) Lactic acid bacteria fermentation: inoculate 0.5% lactic acid bacteria of the weight of the soaking material in a fermenter, ferment for 10 hours at 42°C until the pH is 4.0, and the total acidity is 4.6g / mL; the lactic acid bacteria are Strept...

Embodiment 3

[0053] A preparation method of licorice fermented beverage, comprising the following steps:

[0054] (1) Grinding: Grind licorice and mint to 50 mesh respectively, cook and fry tartary buckwheat until fragrant, crush to 60 mesh, mix evenly to obtain a mixture, the weight ratio of licorice, mint and tartary buckwheat in the mixture is is 100:3:6;

[0055] (2) Soaking: Soak the mixture in step (1) and water according to the material-to-liquid ratio of 1g: 22mL, shake for 2 hours, until the content of glycyrrhizic acid is 0.08%, and obtain the soaked product;

[0056] (3) Sterilization: transfer the material soaked in step (2) into a fermenter, add 5% glucose by weight of the soaked material, and sterilize;

[0057] (4) Lactic acid bacteria fermentation: inoculate 0.8% lactic acid bacteria of the weight of the soaking material in a fermenter, ferment for 9 hours at 40°C until the pH is 4.1, and the total acidity is 4.8g / mL; the lactic acid bacteria are Streptococcus thermophilus...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Acidity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com