Pickling device and production method thereof

A production method and product technology, which are applied in the production of pickle devices and the field of pickle devices, can solve problems such as easy deformation, hidden dangers to user safety, easy to cut hands at the mouth, etc., so as to improve production efficiency, reduce labor costs, and reduce labor costs. Easy to break effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

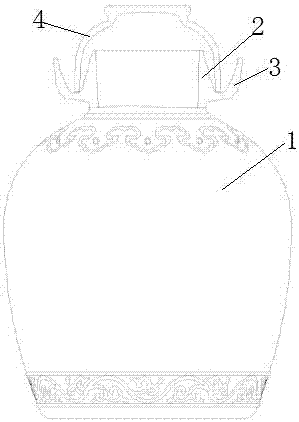

[0022] A kind of pickling device, comprising a tank body, the upper end of the tank body is provided with an inlet, and the outside of the inlet adopts a liquid seal groove integrally formed by automatic stamping, and a sealing bowl cover is placed in the liquid seal groove, and the seal The bowl cover is formed by automatic stamping.

[0023] Specifically, the upper edge and the lower edge of the tank body are provided with decorative patterns.

[0024] Specifically, the sealing bowl cover is formed by automatic stamping.

[0025] The present invention also provides a production method of a pickling device, comprising the steps of:

[0026] S1, raw material selection: choose SiO2, Al2O3, CaO, MgO, Na2O, K2O and H3BO3 as raw materials;

[0027] S2. Raw material blending: take materials according to parts by mass, take 68-72 parts of SiO2, 2-4 parts of Al2O3, 7-10 parts of CaO, 1-2 parts of MgO, 4-6 parts of Na2O, 8-10 parts of K2O and 5 parts of H3BO3 -7 parts, fully mixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com