Phase difference compensation membrane manufacturing equipment and method

A production method and compensation film technology, which is applied in the field of phase difference compensation film production equipment, can solve the problems of high scrap rate, poor stretching accuracy, and complex structure, and achieve the effects of reducing scrap rate, high stretching accuracy, and simplifying the structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

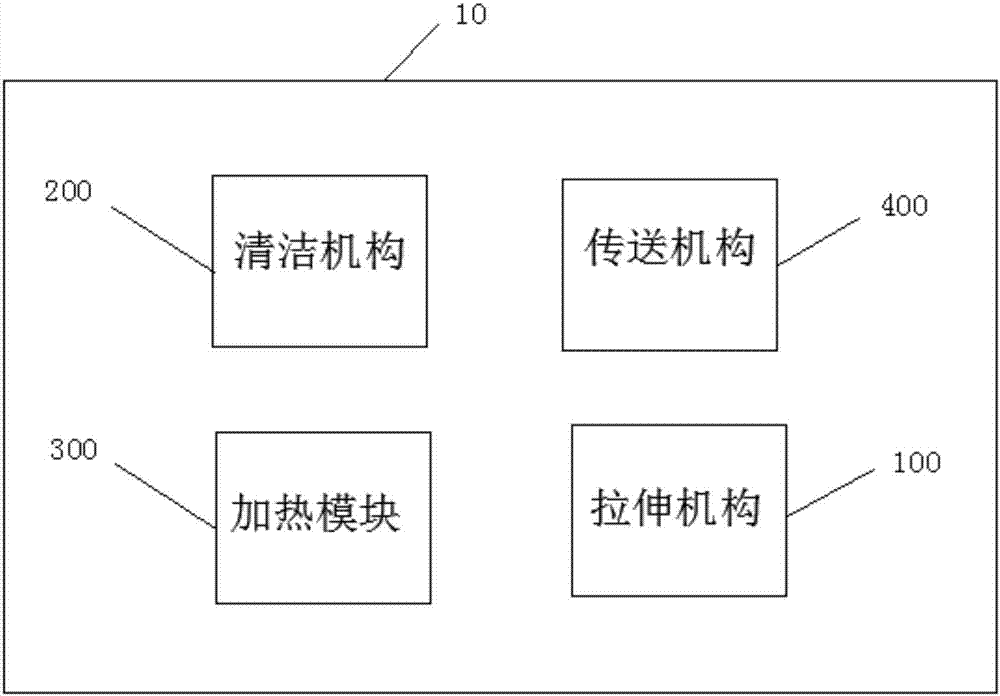

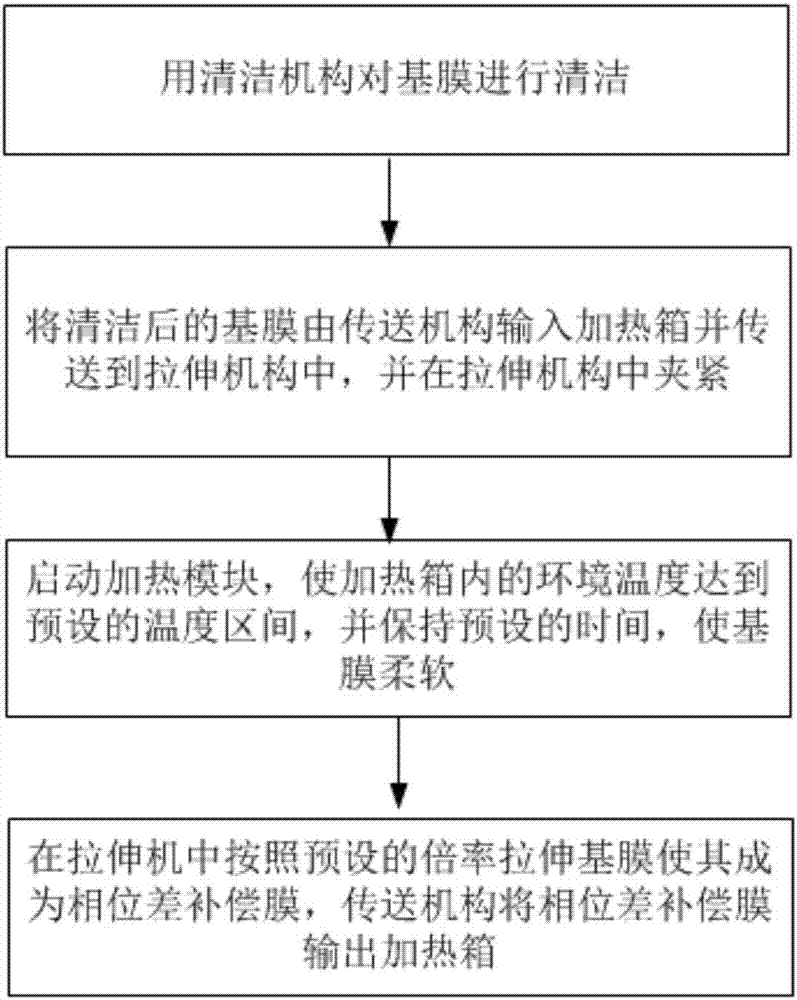

[0047] see figure 1 , figure 2 , the present embodiment provides a retardation compensation film manufacturing device 10 and a method, regarding the retardation compensation film manufacturing device 10 . It includes a cleaning mechanism 200 , a heating box, a stretching mechanism and a transport mechanism 400 .

[0048] Wherein, the cleaning mechanism 200 is arranged outside the heating box, and the cleaning mechanism 200 is used to clean the base film. A heating module 300, a transmission mechanism 400 and a stretching mechanism are arranged in the heating box. The stretching mechanism is used to stretch the heated base film according to a preset ratio to make it a retardation compensation film. The transmission mechanism 400 is used to clean the The final base film is input into the stretching mechanism and the phase difference compensation film formed after stretching is output to the heating box.

[0049] As a preferred conveying mechanism 400, it includes multiple pa...

Embodiment 2

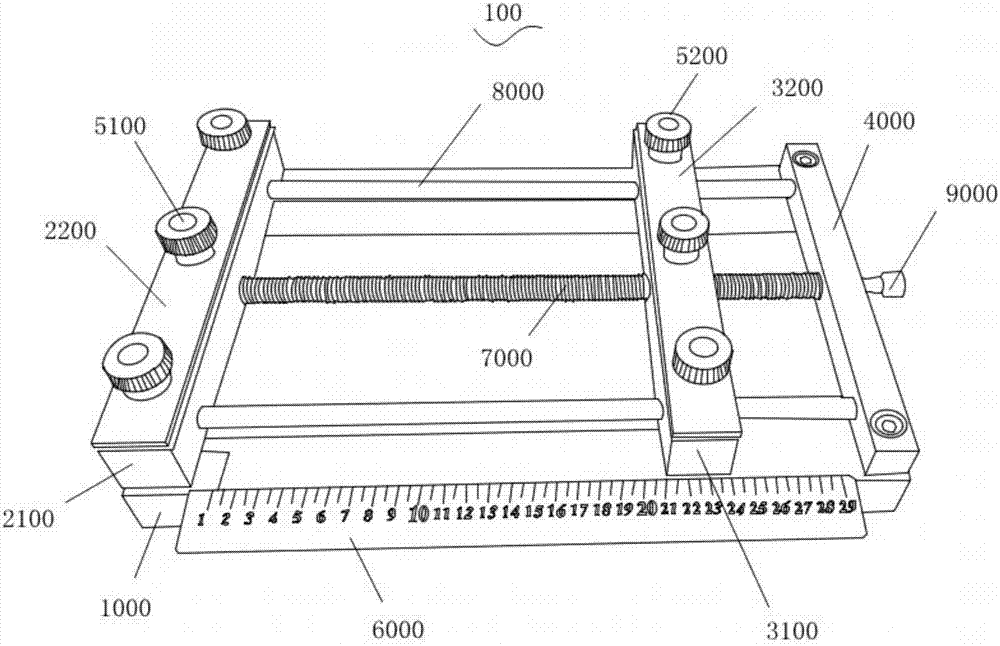

[0083] see image 3 , the present embodiment provides a retardation compensation film production equipment 10, compared with the embodiment 1, the main difference of the present embodiment is:

[0084] The first fixing plate 2100 is provided with a second threaded hole matched with the screw rod;

[0085] And / or, the fixing base 4000 is provided with a third threaded hole matched with the screw rod.

[0086] In Embodiment 1, the first fixing plate 2100 and the fixing seat 4000 cooperate with the screw rods to be bearings.

[0087] When the first fixing plate 2100 is provided with a second threaded hole cooperating with the screw rod, and the fixing base 4000 is provided with a third threaded hole cooperating with the screw rod. The screw rod is threadedly connected with the first fixing plate 2100 and the fixing seat 4000, and when the screw rod rotates, it will extend into or out from the second threaded hole and the third threaded hole.

[0088] Other features in this embod...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com