Assembled type butt joint of duplex type concrete-filled steel tube column and connection method

A technology of steel pipe concrete columns and connection methods, which is applied in the direction of architecture and building construction, can solve the problems of slowing down the construction progress of structures, high requirements for coordinated construction, and increasing the cost of building structures, so as to reduce construction difficulty and workload, and avoid vertical Correction work and improvement of construction efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

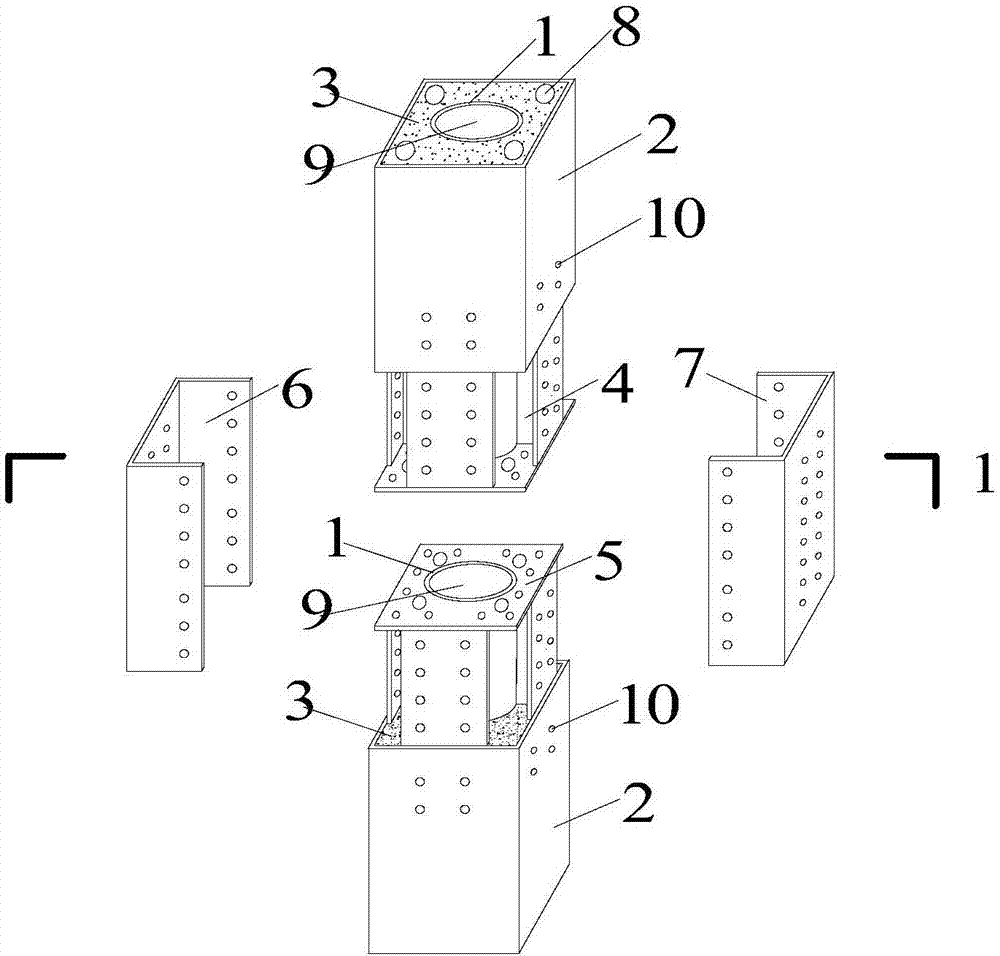

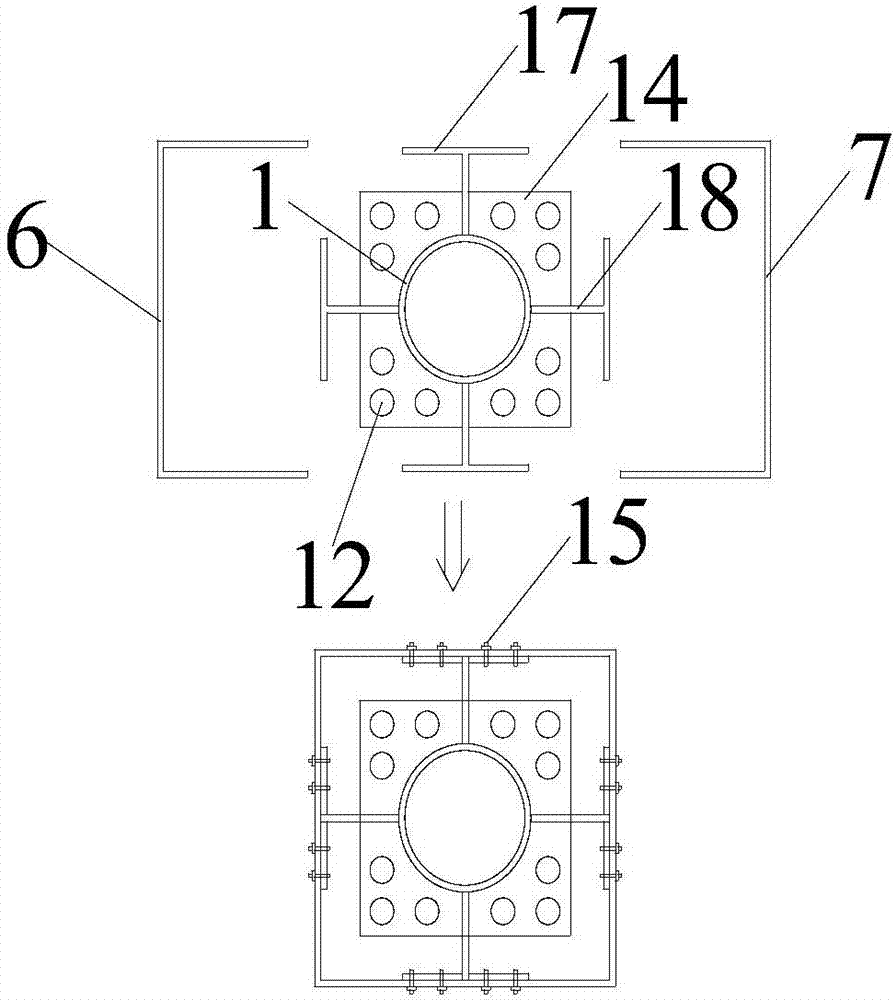

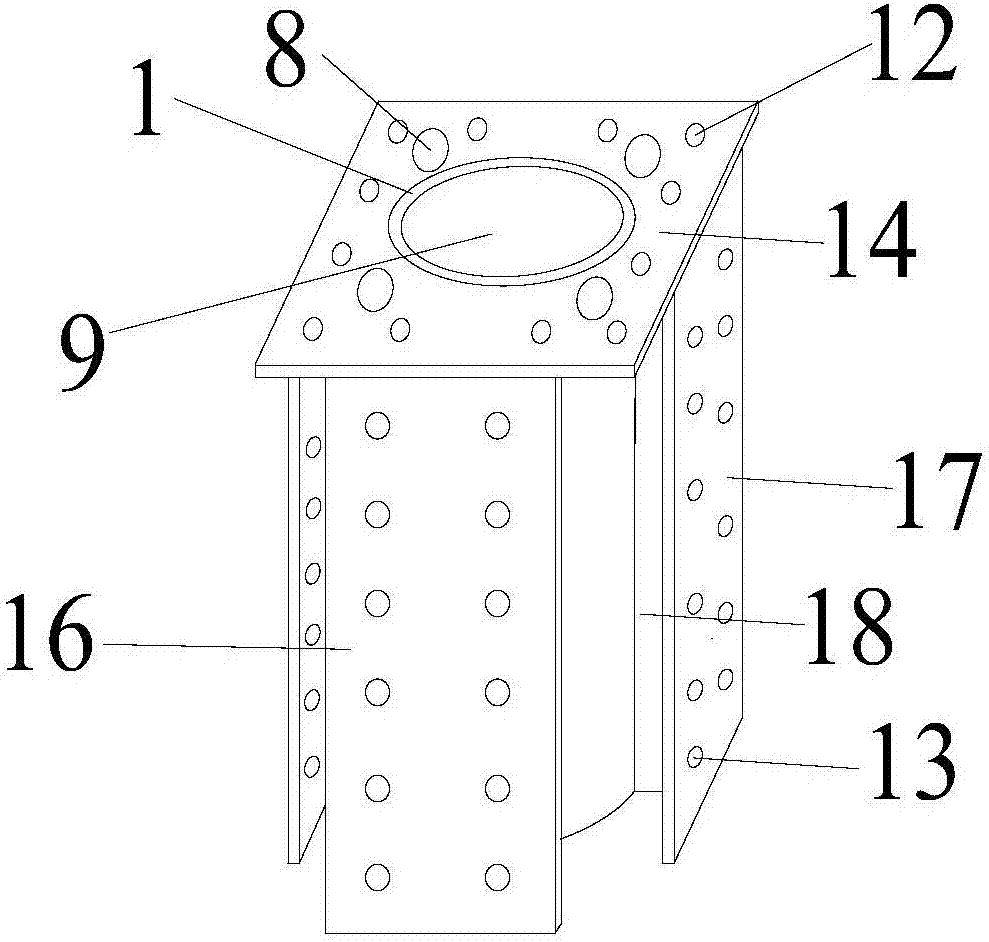

[0034] Such as figure 1 and image 3 , this embodiment provides a composite steel pipe concrete column assembled butt connection node, including a first node joint 4 , a second node joint 5 , a first channel steel joint 6 , and a second channel steel joint 7 . Wherein, the first and second node joints (4, 5) are made up of two front connecting plates 16, two side connecting plates 17 and connecting panels 14, and the two front connecting plates 16 and the two side connecting plates are connected by four Laths 18 are surrounded and welded symmetrically around the inner steel pipe 1. After the welding is completed, the connecting panels 14 are respectively welded at the ends of one end to form the butt joint connection nodes of the upper and lower columns.

[0035] In this embodiment, the first node joint 4 and the second node joint 5 adopt the same size specification, and the first channel steel joint 6 and the second channel steel joint 7 also adopt the same size specificatio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com