Method and device for under-shaft releasing

A technology of sealing section and tie rod, which is used in drilling equipment, earthwork drilling, wellbore/well components, etc., to achieve the effect of convenient connection, simple structure and precise control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

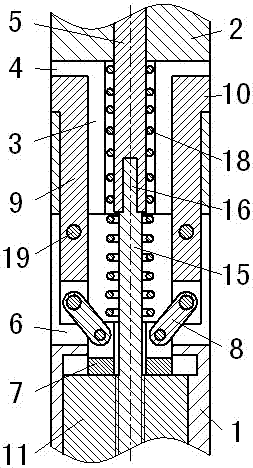

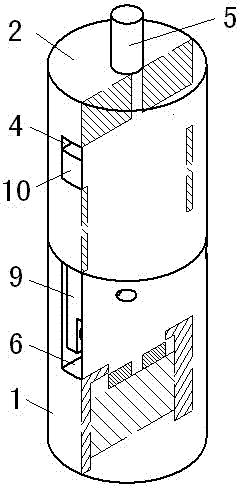

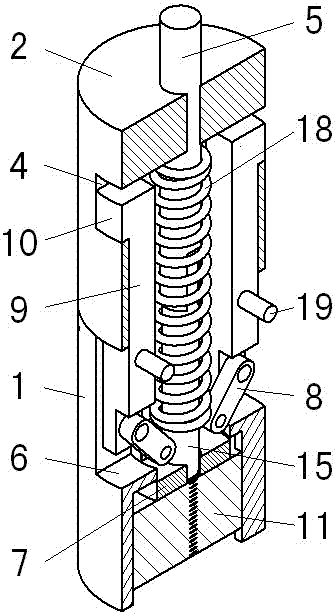

[0026] In this example, the pull rod 9, the connecting rod 8, and the slider 7 are hinged through a pin shaft 19 to form a linkage mechanism. A connecting rod groove 6 is radially opened on the top of the sealing section 1, and the connecting rod groove 6 is a through groove. The middle part of the pull rod 9 is fixed on the outer tube of the sealing section 1 through a pin shaft 19, and the pull rod 9 can rotate around the pin shaft 19. The outer tube of the delivery instrument 2 is provided with a pull rod groove 3 and a bayonet 4, and the hook 10 at the top of the pull rod 9 can be inserted into the inside of the outer tube of the delivery instrument 2, and is connected to the radially upward bayonet 4 of the outer tube of the delivery instrument 2. Hook the surface, stage clip 18 locks the mechanism, and pull rod 9 tightens the delivery instrument 2 outer tube to complete the connection of the delivery instrument 2 and the sealing section 1. Hand-losing process: the rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com