A magnetic field-assisted microfluidic carbon nanofiber size exclusion chromatography separation method

A technology of size exclusion chromatography and carbon nanofibers, which is applied in the field of separation of micro-nano-scale substances, can solve the problems of difficult separation of target substances, labeling of target substances, poor separation efficiency, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

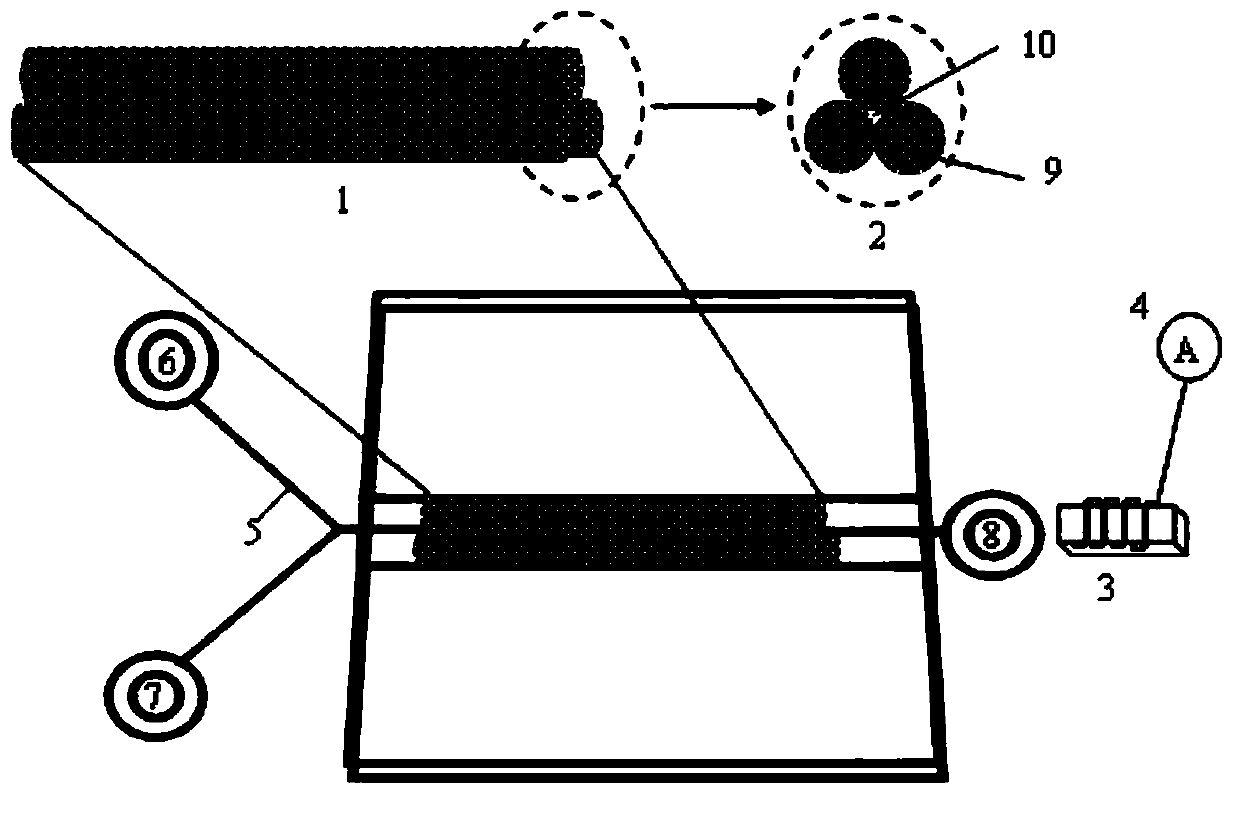

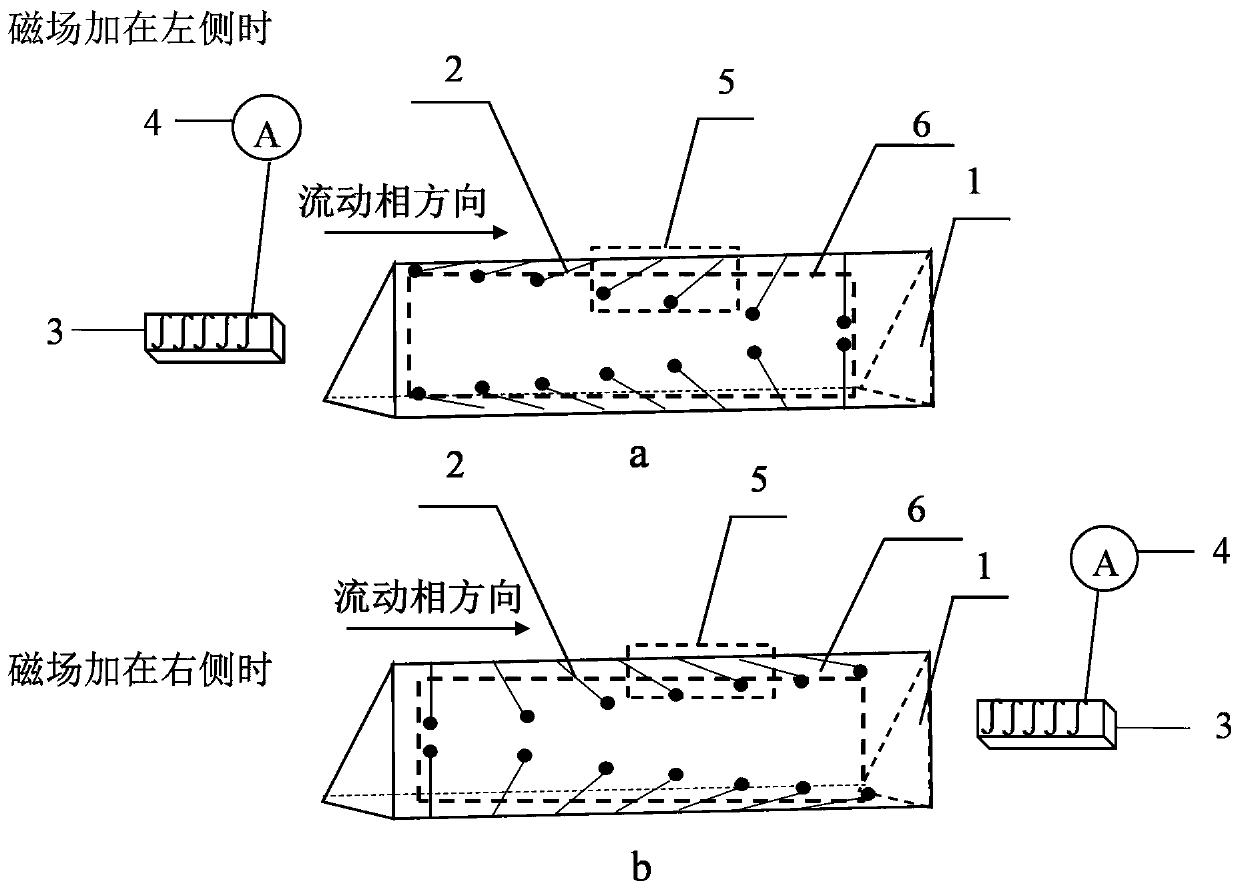

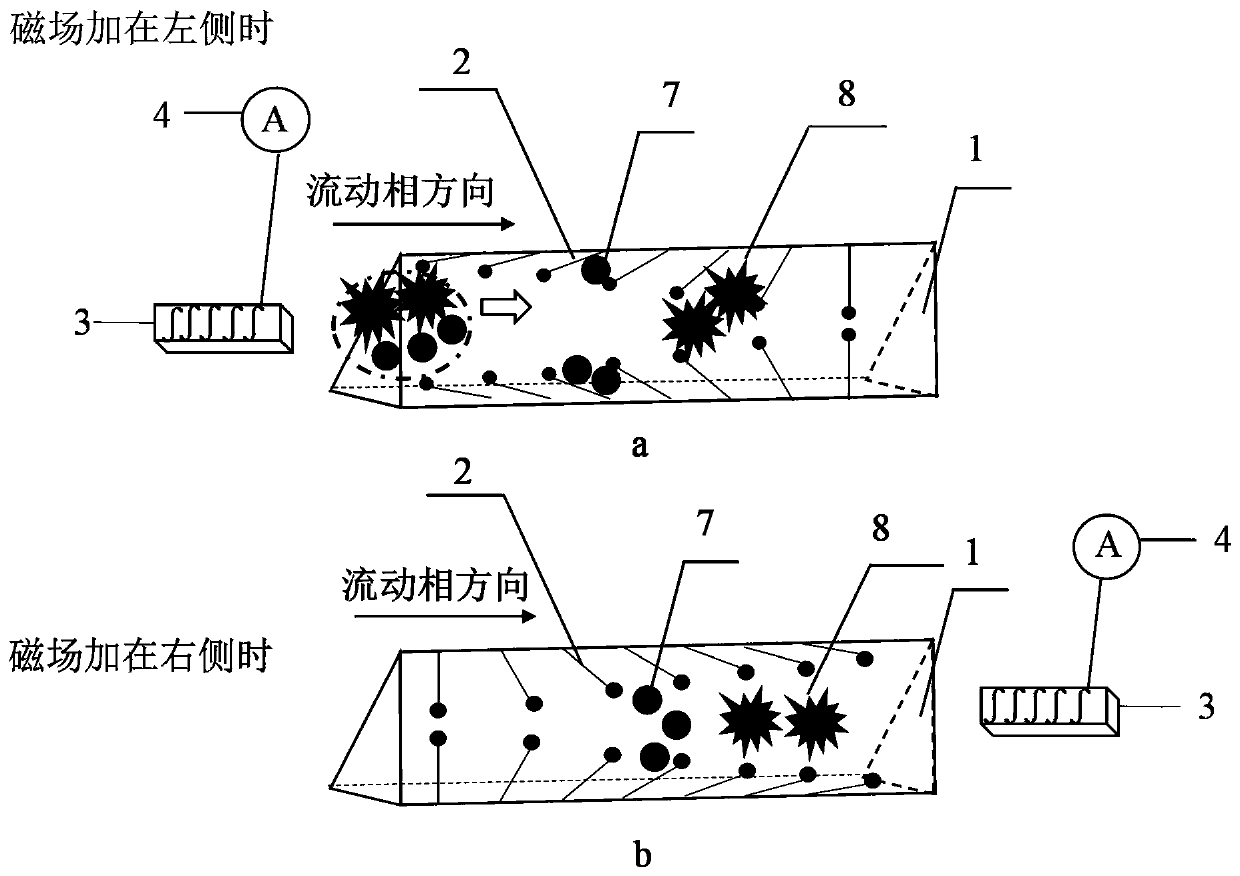

Embodiment 1

[0052] A quartz optical fiber 1 with an outer diameter of 300 μm is selected as the substrate, and after treatment, carbon nanofibers with a length of 30 μm are grown on its surface by chemical vapor deposition to obtain carbon nanofibers / substrates. Soak in the medium for a few minutes, take out the substrate and dry it naturally, and then use the oxidation reaction and dehydration condensation reaction to modify the magnetic nanoparticles with amino groups to one end of the carbon nanofiber, so that the end of the carbon nanofiber is magnetic, and the magnetic carbon nanofiber / Silica optical fiber 9, three magnetic carbon nanofibers / silica optical fibers of the same specification according to figure 1 Bonding is carried out as shown to form a separation channel 10, which is put into a microfluidic chip, and the separation channel is connected to a sampler 6, a mobile phase injection pump 7, and an ultraviolet detector 8 with a capillary 5, and the ultraviolet detection metho...

Embodiment 2

[0055] Three silica optical fibers of the same specification in Example 1 are bonded and replaced with a silica optical fiber or a pencil core or a quartz capillary tube or a combination of a metal and a quartz glass plate with CNFs on the surface to obtain a separation channel, the result is as follows Figure 4 As shown, the rest are the same as in Example 1, and the separation of micro-nano-sized substances can be realized.

Embodiment 3

[0057] The three silica optical fibers of the same specification in Example 1 were bonded and replaced with two high-purity silica sheets with CNFs on the surface to combine to obtain the separation channel, the results are as follows Figure 5 As shown, the rest are the same as in Example 1, and the separation of micro-nano-sized substances can be realized.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| depth | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com