Casting die and casting method of long-cylindrical shell iron casting with ribbed inner chamber

A technology for iron castings and casting molds, which is applied in the field of casting molds and castings for long cylinder iron castings. It can solve the problems of shrinkage porosity, high failure rate, and sand inclusion, and achieve the reduction of shrinkage porosity, product quality and production efficiency. Improve and widely promote the effect of application value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

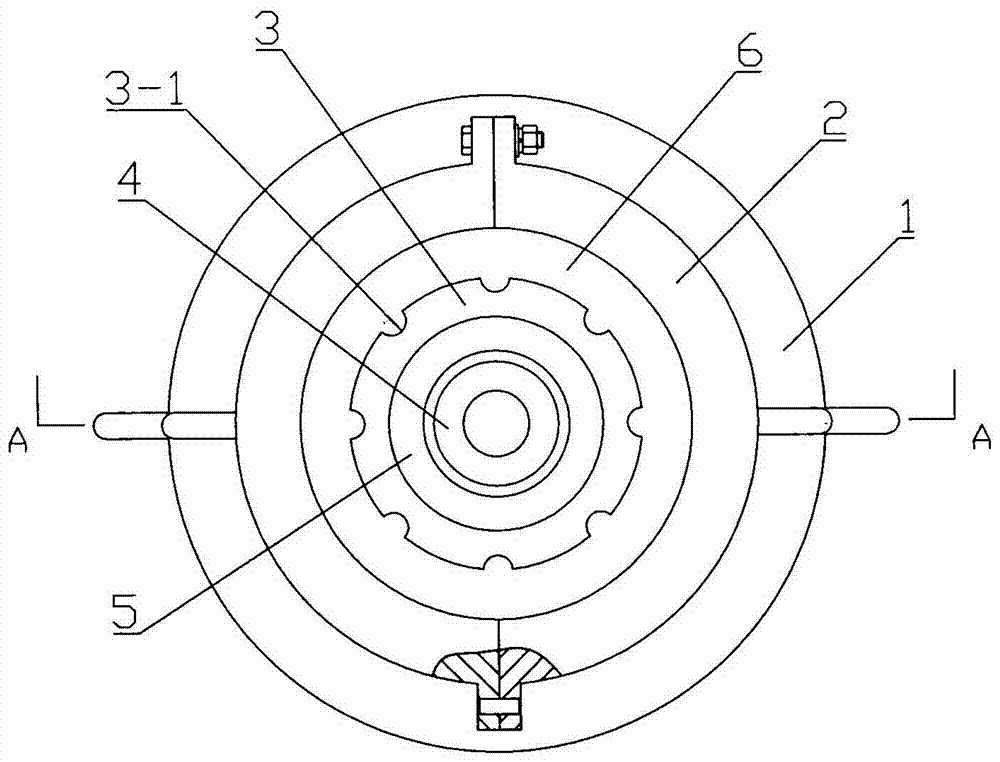

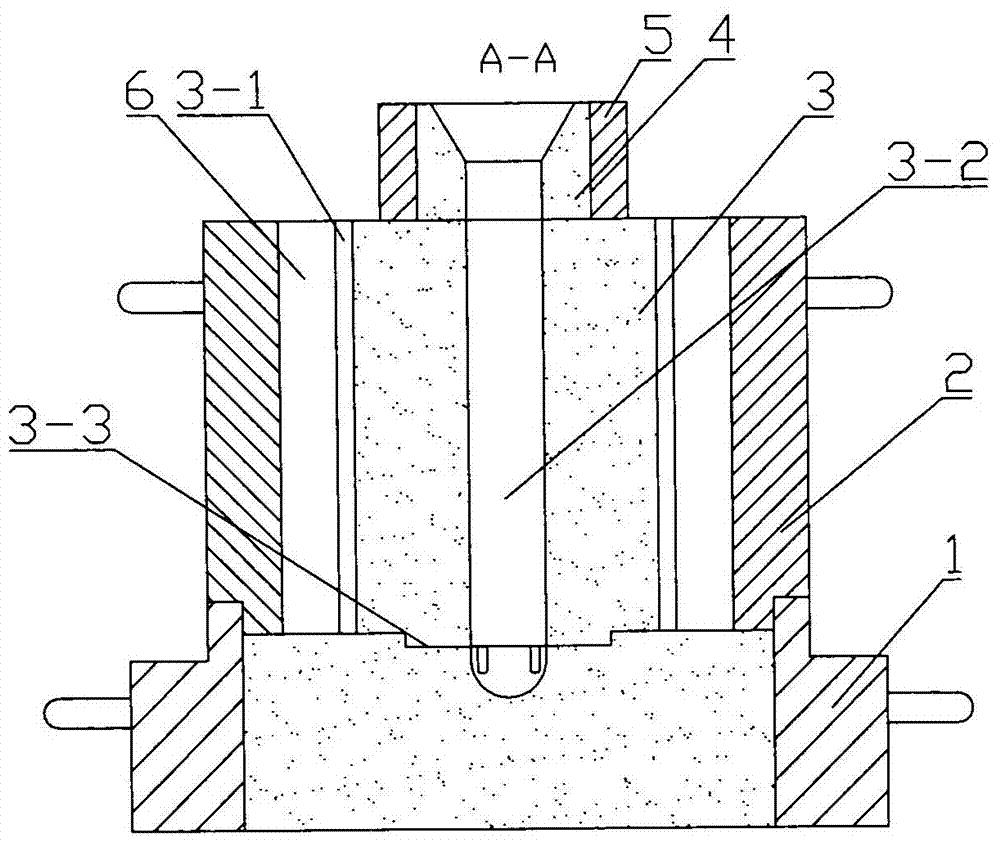

[0027] The first embodiment is a long-tube cast iron casting mold with ribs in the inner cavity, which includes a lower flask 1, a metal outer mold 2, a green sand core 3, a sprue cup 4, and a pressure box iron 5.

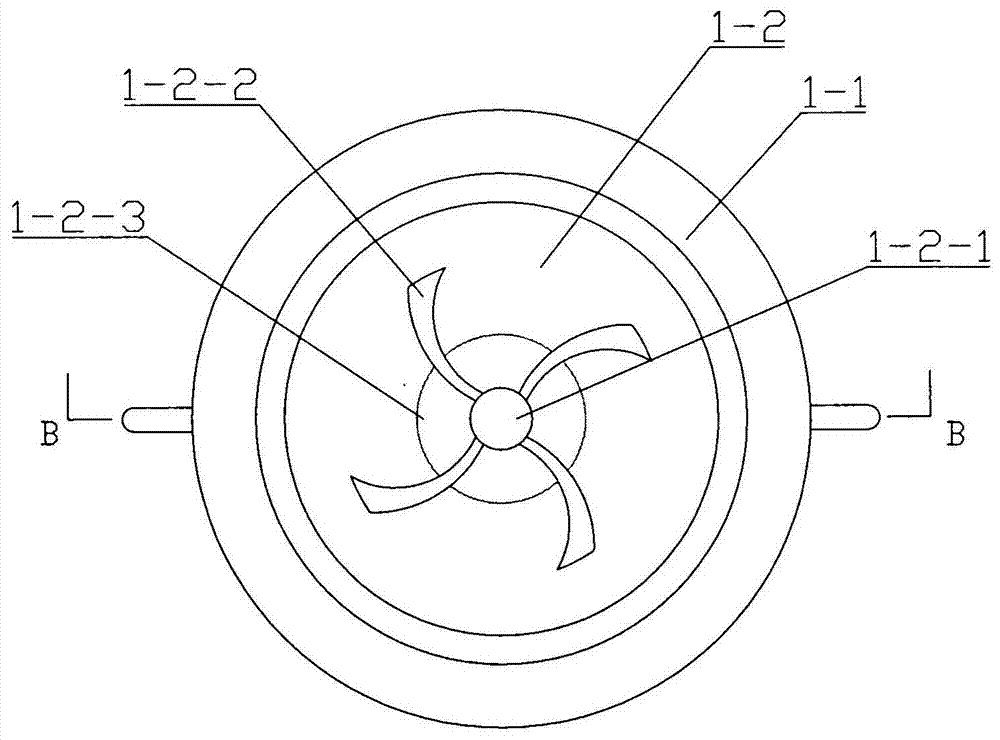

[0028] The lower sand box 1 includes a box body 1-1 and molding sand 1-2 filled in the box body 1-1, the moisture content of the molding sand 1-2 is controlled at 3.5%, and the center part of the upper end surface of the molding sand 1-2 is provided A pouring cavity 1-2-1, around the pouring cavity 1-2-1, there are four evenly distributed spiral runners 1-2-2 with a semicircular bottom, the spiral runners 1-2-2 and The pouring cavity 1-2-1 communicates, and a positioning hole 1-2-3 is provided on the upper end surface of the molding sand 1-2.

[0029] The metal outer mold 2 is a cylinder composed of two semicircular shells in cross section, and the two semicircular shells in cross section are connected to form a cylinder by bolts and positioning pins.

[0030] The green ...

Embodiment 2

[0036] The second embodiment is a long-tube cast iron casting mold with ribs in the inner cavity, which includes a lower flask 1, a metal outer mold 2, a green sand core 3, a sprue cup 4, and a pressure box iron 5.

[0037] The lower sand box 1 includes a box body 1-1 and molding sand 1-2 filled in the box body 1-1, the moisture content of the molding sand 1-2 is controlled at 4%, and the center part of the upper end surface of the molding sand 1-2 is provided A pouring cavity 1-2-1, around the pouring cavity 1-2-1, there are four evenly distributed spiral runners 1-2-2 with a semicircular bottom, the spiral runners 1-2-2 and The pouring cavity 1-2-1 communicates, and a positioning hole 1-2-3 is provided on the upper end surface of the molding sand 1-2.

[0038] The metal outer mold 2 is a cylinder composed of two semicircular shells in cross section, and the two semicircular shells in cross section are connected to form a cylinder by bolts and positioning pins.

[0039] The green s...

Embodiment 3

[0045] The third embodiment is a long-tube cast iron casting mold with ribs in the inner cavity, which includes a lower flask 1, a metal outer mold 2, a green sand core 3, a sprue cup 4, and a pressure box iron 5.

[0046] The lower sand box 1 includes a box body 1-1 and molding sand 1-2 filled in the box body 1-1, the moisture content of the molding sand 1-2 is controlled at 5%, and the center part of the upper end surface of the molding sand 1-2 is provided A pouring cavity 1-2-1, around the pouring cavity 1-2-1, there are four evenly distributed spiral runners 1-2-2 with a semicircular bottom, the spiral runners 1-2-2 and The pouring cavity 1-2-1 communicates, and a positioning hole 1-2-3 is provided on the upper end surface of the molding sand 1-2.

[0047] The metal outer mold 2 is a cylinder composed of two semicircular shells in cross section, and the two semicircular shells in cross section are connected to form a cylinder by bolts and positioning pins.

[0048] The green sa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com