Double-wire and double-arc digital submerged arc welding power supply

A technology of submerged arc welding and power supply, applied in arc welding equipment, welding equipment, manufacturing tools, etc., can solve the problems of heavy welding machine power frequency transformer, narrow frequency adjustment range, unstable welding, etc., to achieve high work efficiency, high frequency The effect of large adjustment range and stable welding current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

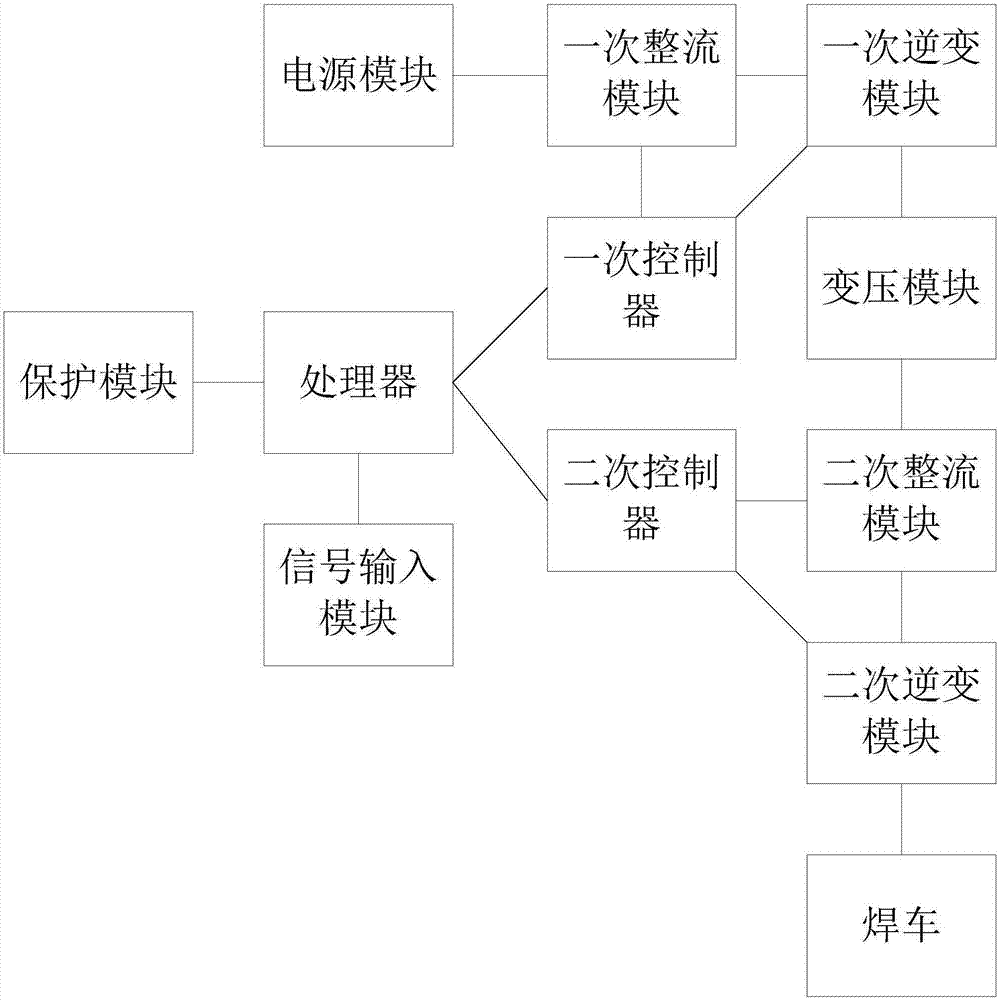

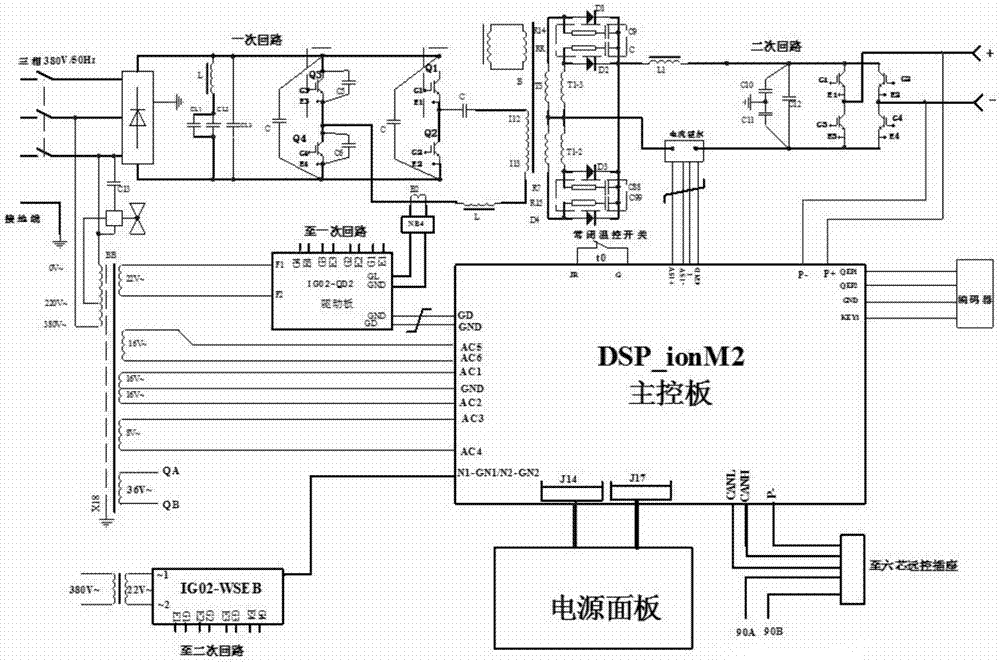

[0022] Such as figure 1 , figure 2 As shown, the double-wire double-arc digital submerged arc welding power supply of the present invention includes a power supply module and a welding car, and a primary rectification module, a primary inverter module, a transformer module, and a secondary rectification module are sequentially connected between the power supply module and the welding car. The module and the secondary inverter module are fast. The three-phase 380V grid power supply is rectified by the power frequency rectifier bridge, and then supplied to the inverter to be converted into high-frequency AC, and then high-frequency transformation and rectification are performed. The output signal is controlled by feedback to obtain a smooth and continuously adjustable DC power supply. , sent to the secondary inverter for conversion, the inverter is converted into low-frequency AC, supplied to the welding car, and the workpiece is automatically welded by the welding car. It al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com