stone crusher

A stone crusher and main engine technology, applied in stone processing tools, stone processing equipment, work accessories, etc., can solve problems such as unfavorable operation, hydraulic system volume, large weight, limited impact force of stones, etc., and achieve simple structure and portable Convenient and flexible application effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

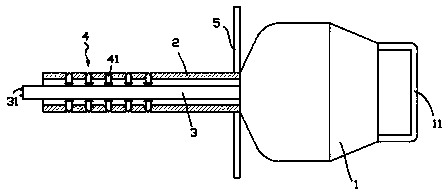

[0013] exist figure 1 In the shown embodiment one, the lithotripter includes a main machine 1; a handrail 11 is provided at the rear of the main machine 1; A shaft 3 that extends axially and extends out of the intubation tube 2; in the first embodiment, the shaft 3 is fixed to the host 1; the outer end of the shaft 3 is provided with a discharge electrode 31 that can generate an arc; The host 1 is provided with a high-voltage power supply, which can apply high voltage to the discharge electrode 31 to make it discharge; two rows of side top mechanisms 4 are evenly distributed on the side of the intubation tube 2 in the circumferential direction, and the side top mechanisms 4 include components that communicate with the inside of the intubation tube. The slideway, and the slide post 41 located in the slideway; the outer end of the slide post 41 forms a pointed cone, and when the slide post 41 laterally slides to the outermost end, the outer end of the slide post 41 is pushed out...

Embodiment 2

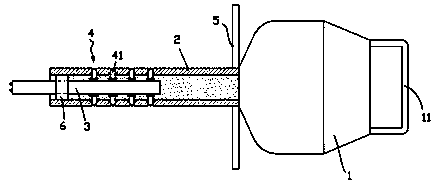

[0018] for figure 2 The second embodiment shown is different from the first embodiment in that the shaft 3 is fixed on the axial sliding plug 6 inside the intubation tube 2; The airtight fit is always maintained, and the airtight fit is always maintained between the sliding column 41 and the slideway; hydraulic oil is sealed in the cannula 2; the sliding column 41 is made of ferromagnet, and in the natural state, each The spool 41 is automatically retracted into the inside of the intubation tube 2 by the attraction of the shaft 3 until the inner end of the swipe 41 touches the shaft 3, and the shaft 3 itself constitutes the inner limit body of each slid 41; The inner end of the sliding column 41 is rounded. In the non-working state, the hydraulic oil in the cannula 2 extends axially to the maximum size, which can make the shaft 3 push out to the limit, and is easy to contact the explosives in the stone hole; When an explosion occurs, the impact force of the high-pressure ga...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com