Double planetary gear train multi-mode hybrid power system and control method

A technology of a hybrid power system and a double planetary gear train, which is applied in the directions of hybrid power vehicles, electric braking systems, power units, etc., can solve the problem of engine characteristic violation, the inability of the engine to output power, and the inability to realize the hybrid power series working mode and parallel working. Mode and other issues, to achieve the effect of mature configuration and compact structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] This embodiment is only a preferred technical solution, and the various components and connection relationships involved are not limited to the following implementation described in this embodiment. The configuration and connection relationship of the various components in the preferred solution can be Carry out arbitrary permutations and combinations to form a complete technical solution.

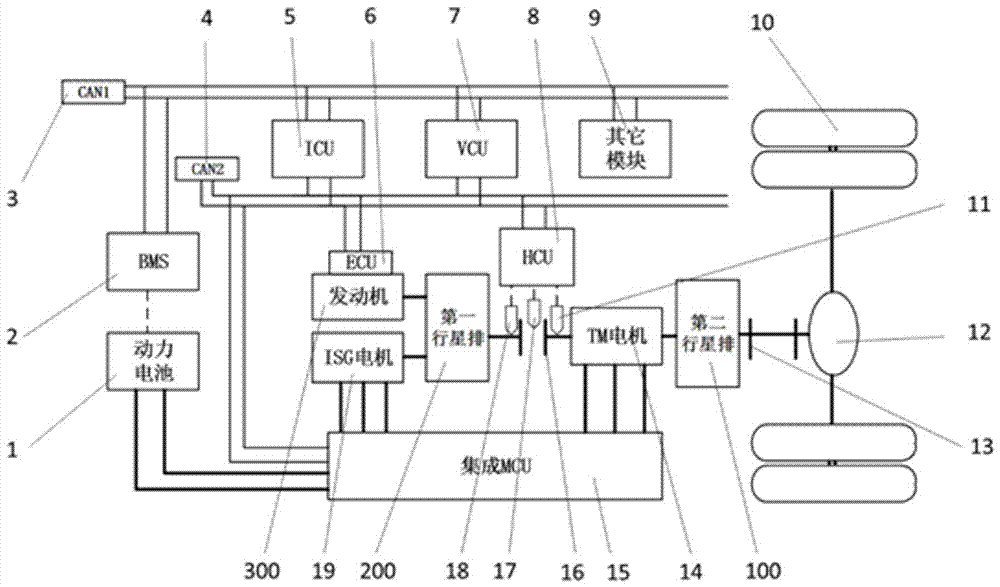

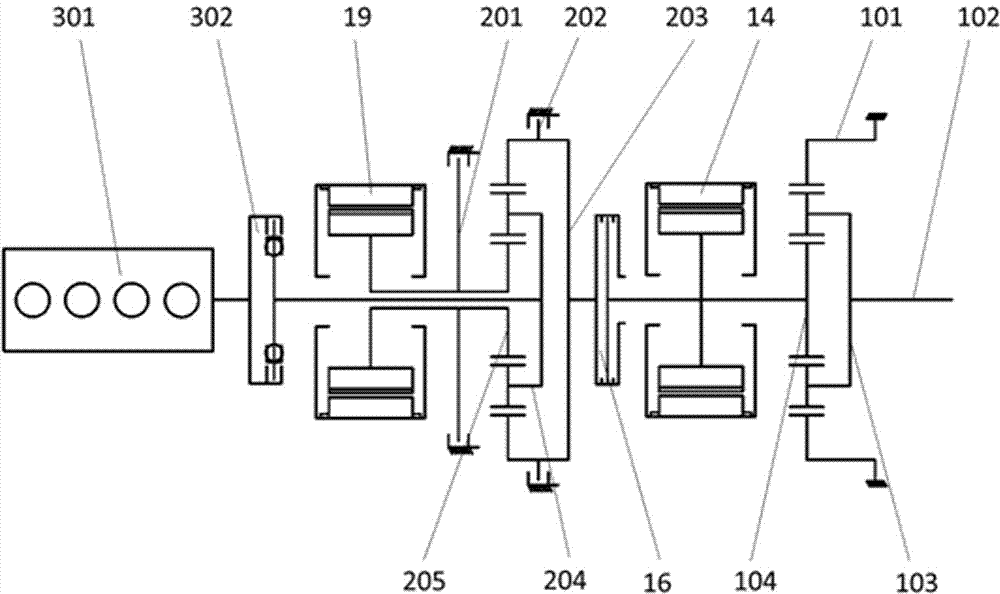

[0041] Combine below figure 1 , 2 Describe in detail the technical solution of the dual planetary gear train multi-mode hybrid power system:

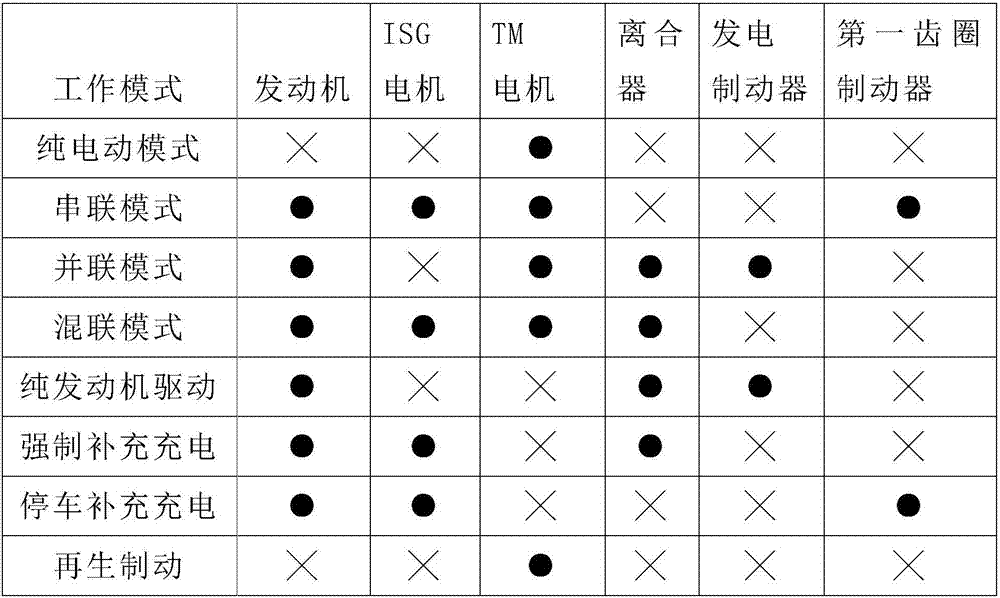

[0042] A dual planetary gear train multi-mode hybrid power system, including an engine assembly 300, an integrated starter generator motor 19, a main drive motor 14, a first planetary gear train assembly 200 and a second planetary gear train assembly 100, the two The sets of planetary gear trains are independent of each other in terms of their internal connection and movement. The engine assembly 300 includes the engine 301, the first plan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com